A low-noise diamond saw blade

A diamond saw blade, low-noise technology, used in stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of reduced service life, large noise, substrate deformation, etc., and achieve the effect of improving service life and reducing cutting noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

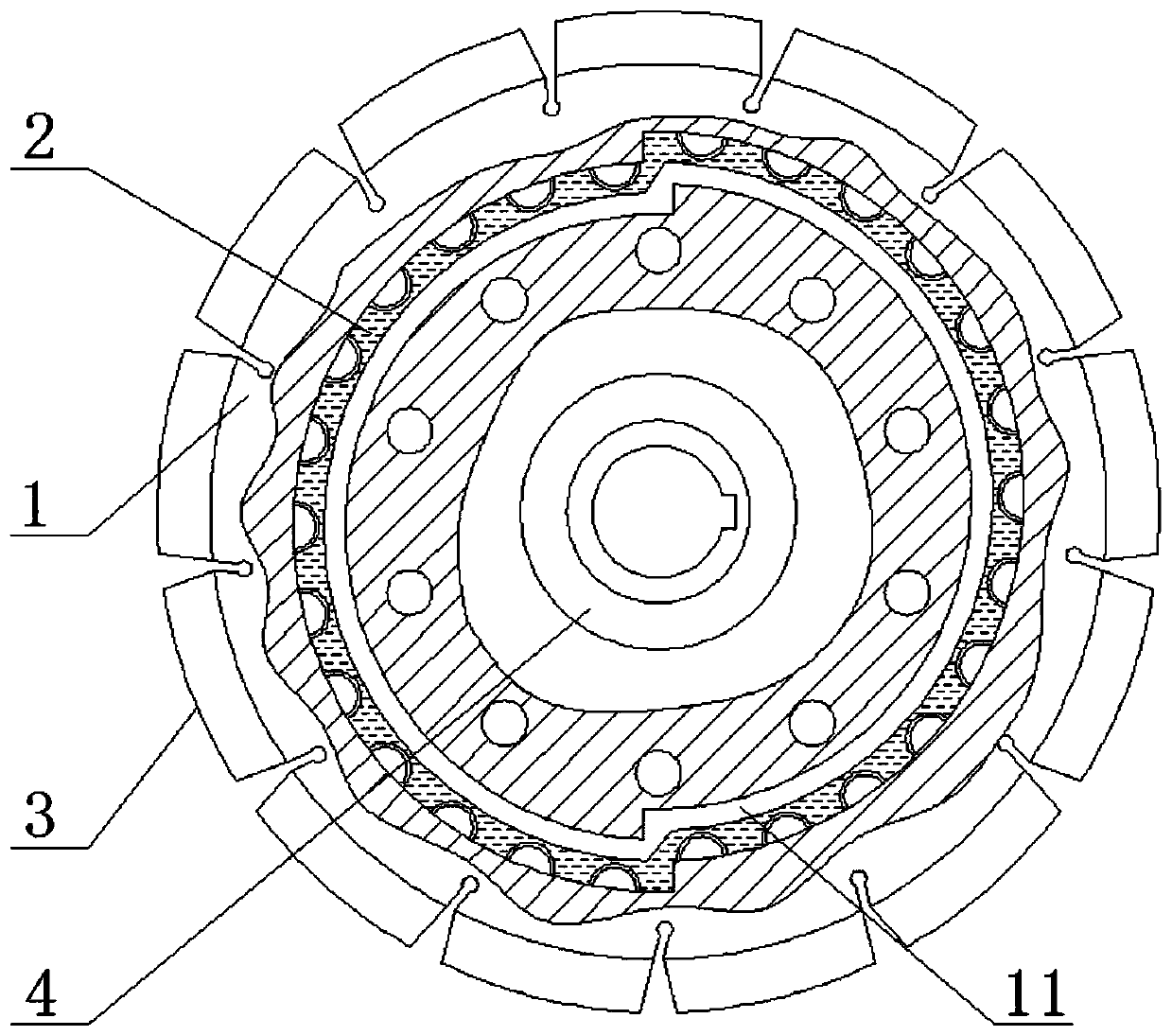

[0032] As a preferred embodiment of the present invention, the outer side of the base circular plate 1 is located between the two diamond segment pieces 3 with inclined chip guide penetration grooves.

[0033] As a preferred embodiment of the present invention, the volume of the liquid gallium alloy 2 is half of the inner volume of the staggered eccentric guide channel 11 .

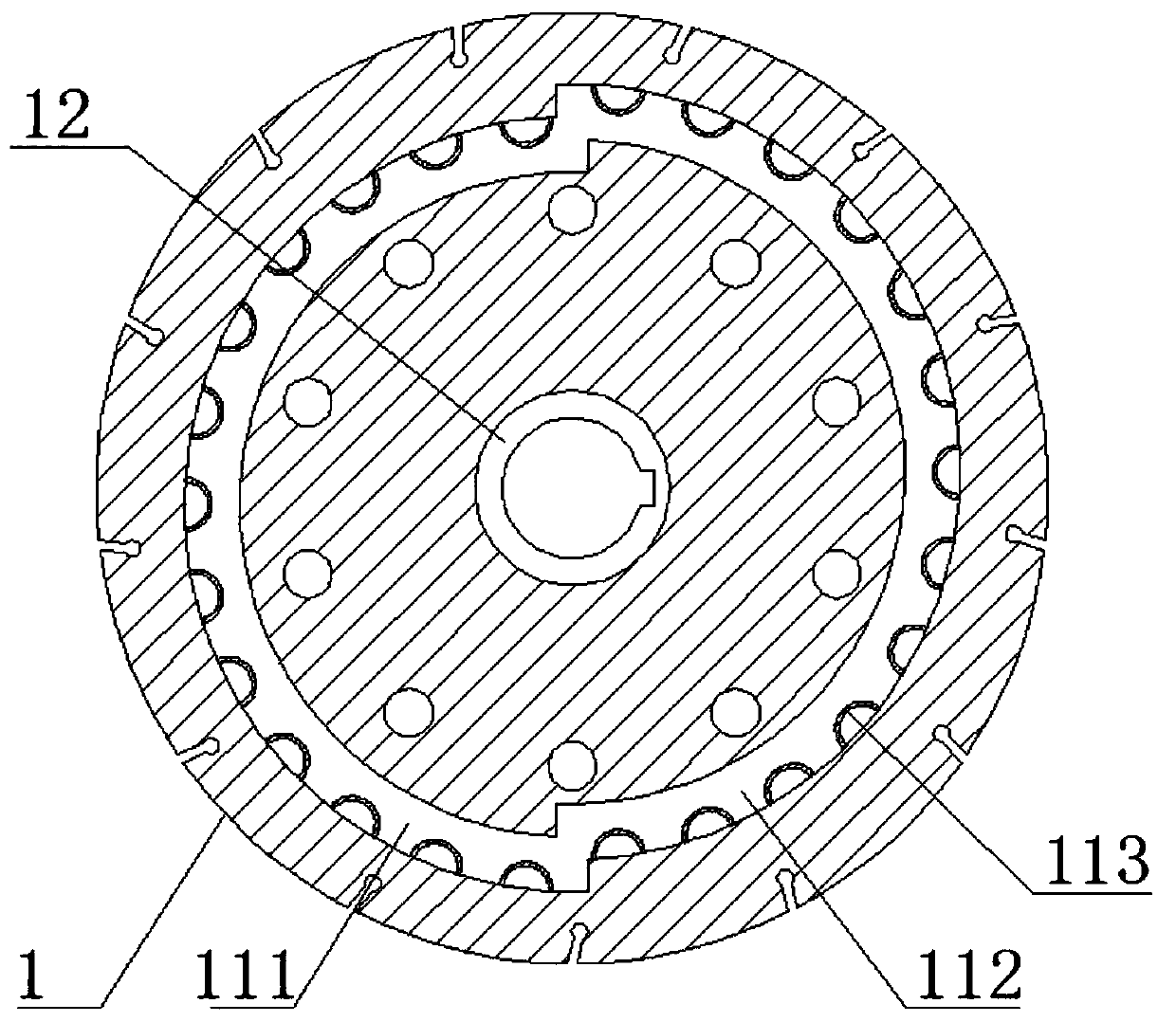

[0034] As a preferred embodiment of the present invention, the first annular channel 111 and the second annular channel 112 have the same size and specification, and the midpoint of the line connecting their centers coincides with the center of the base circular plate 1 .

[0035] As a preferred embodiment of the present invention, both ends of the thin-walled circular arc plate 113 are welded to the inner sidewalls of the first annular channel 111 and the second annular channel 112 and can vibrate.

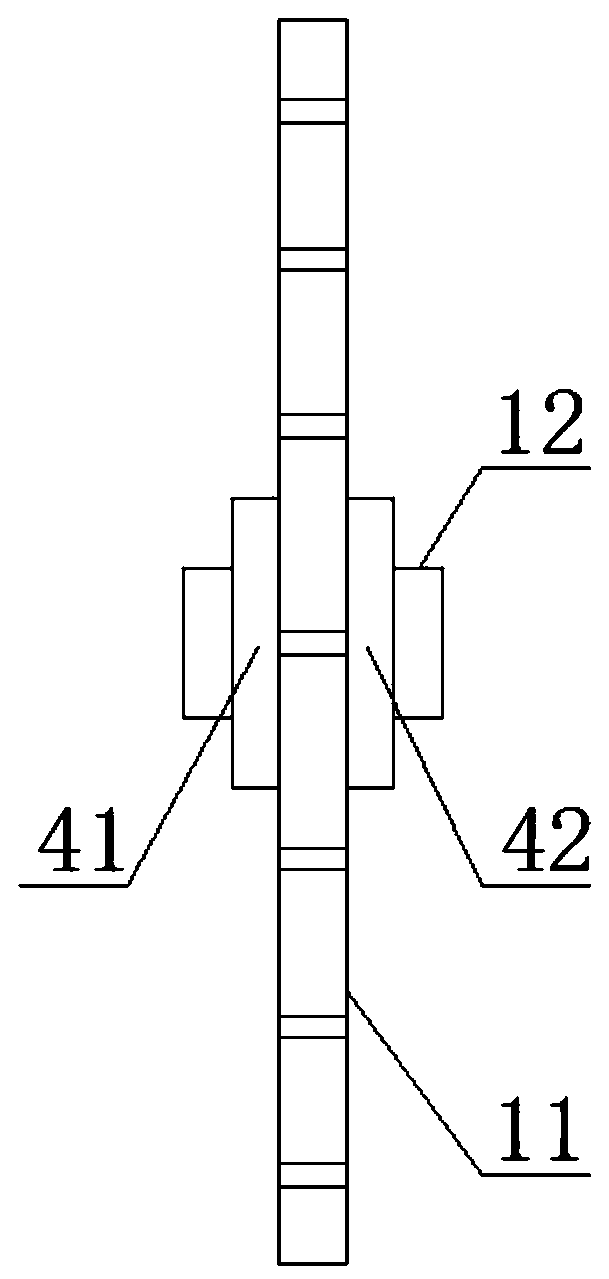

[0036] As a preferred embodiment of the present invention, cooling holes are uniformly opened on the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com