Noise-reducing air flue shell and nitrogen and oxygen separating device employing same

A shell and air duct technology, which is applied in the field of noise-reducing air duct shells, can solve problems such as affecting sleep, high noise, and complicated production and assembly, and achieve the effect of facilitating mass production, obvious economic benefits, and simple and delicate structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

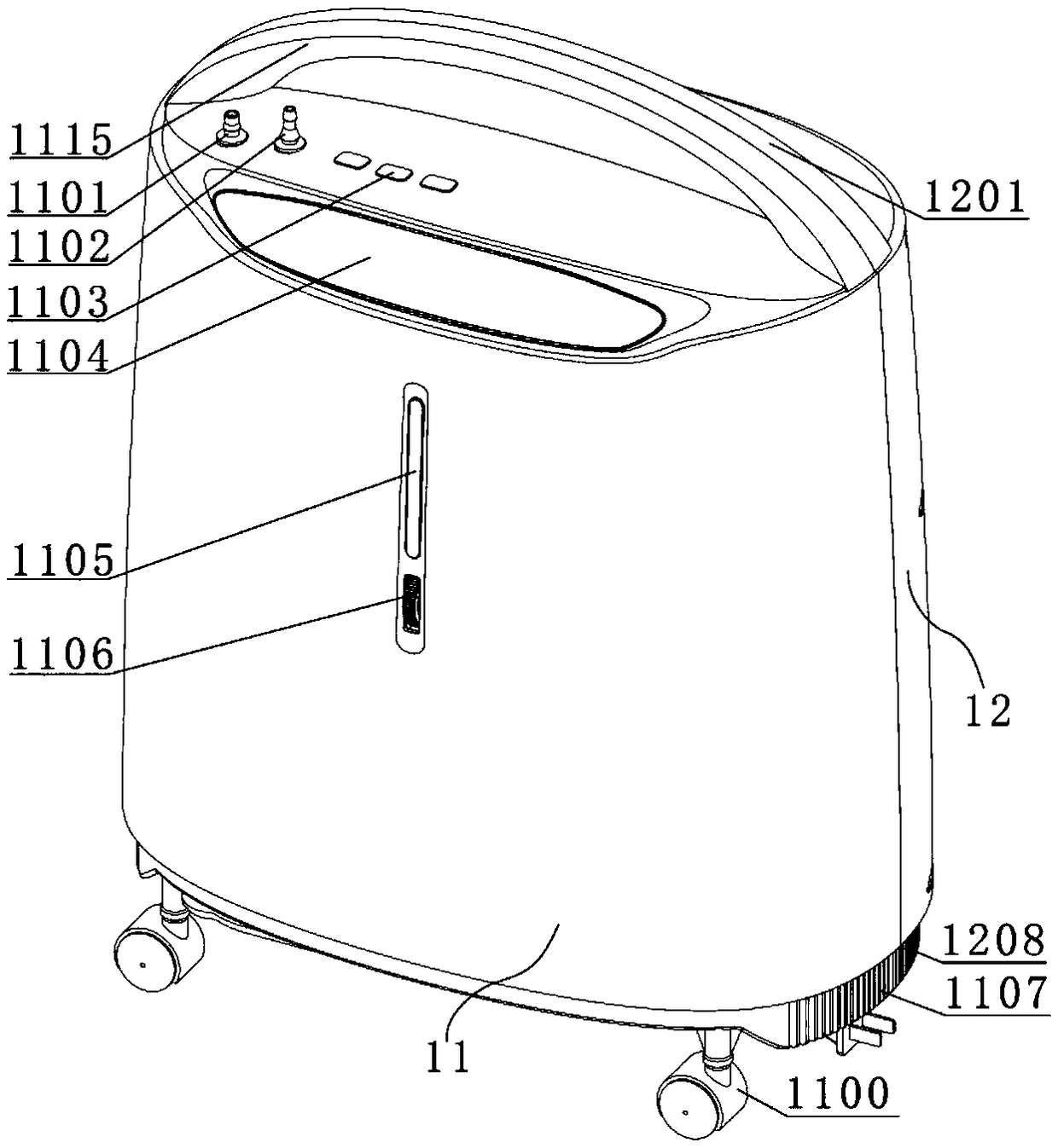

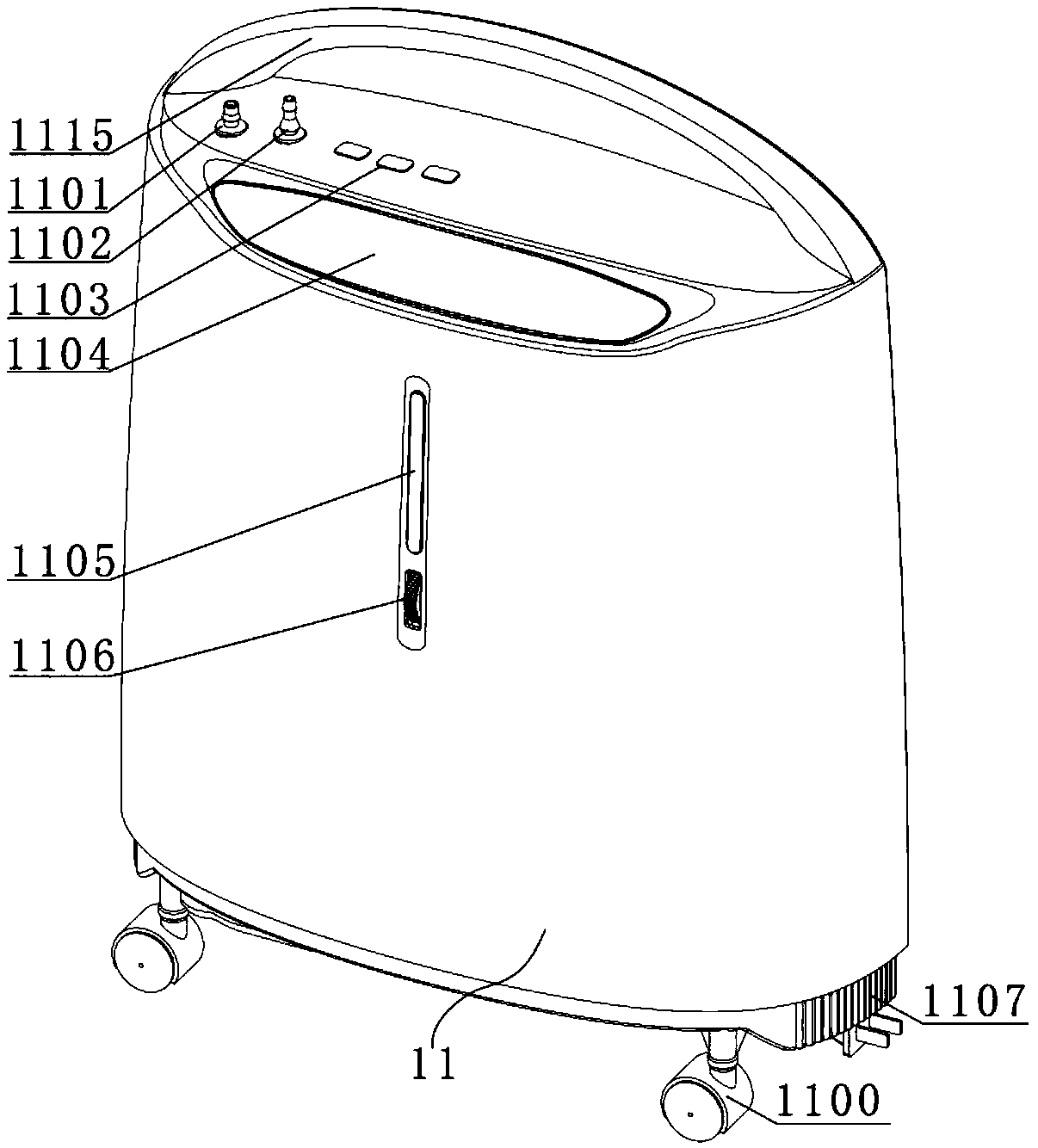

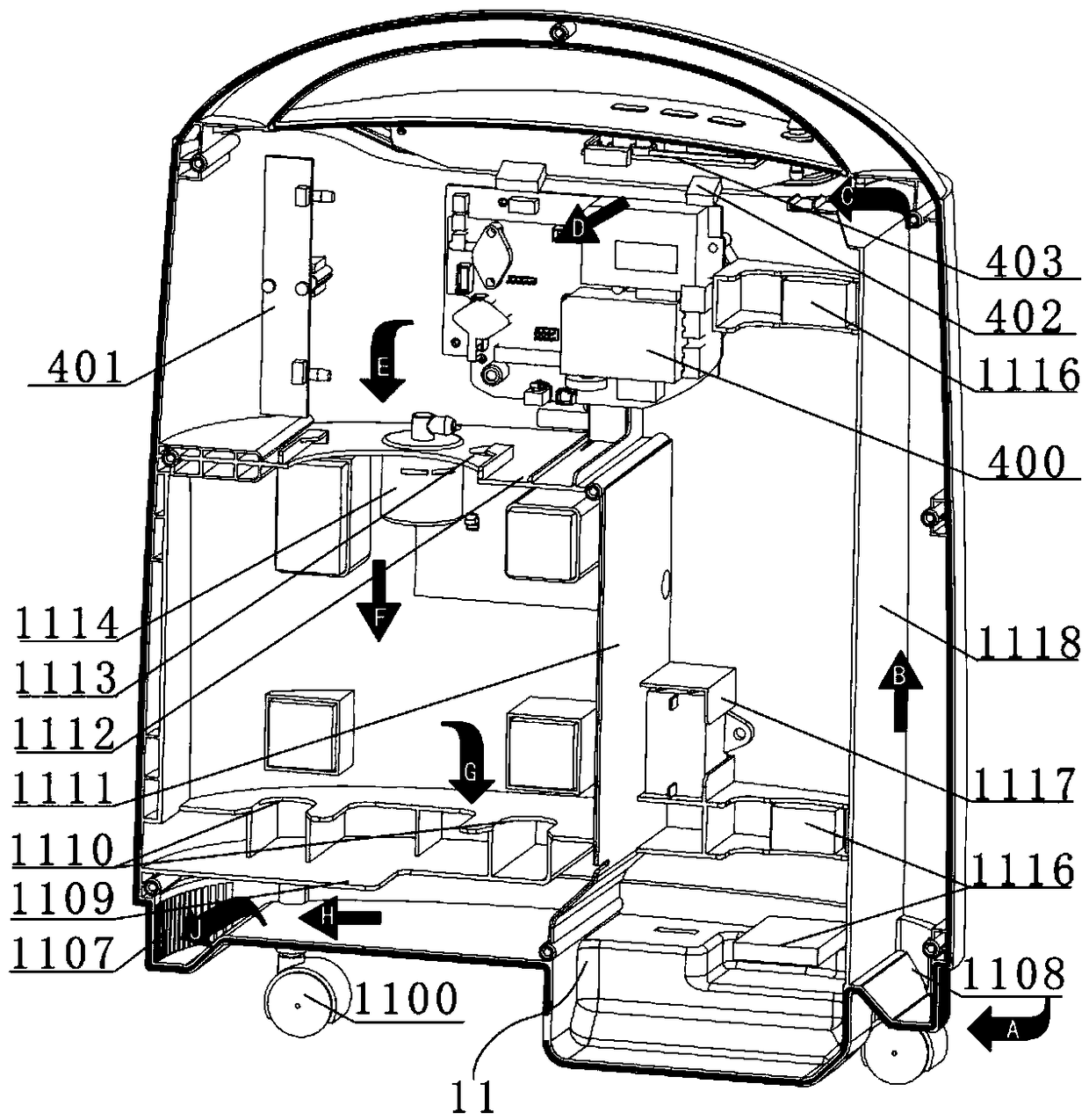

[0035] refer to Figure 1 to Figure 7 As shown, the noise reduction air duct housing of this embodiment only includes the first sub-housing 11 and the second sub-housing 12, and the first sub-housing 11 and the second sub-housing 12 are located on the front and rear sides of the housing respectively. , the shapes of the two are basically symmetrically arranged, and the two sub-housings are assembled to form a complete housing (the two sub-housings can be fixedly connected by means including but not limited to socket structures, buckle structures, screws or gluing) ), the first sub-housing 11 and the second sub-housing 12 are assembled to form an oxygen-generating component accommodating cavity inside, and all oxygen-generating components are placed in the accommodating cavity inside the housing.

[0036] The inner walls of the first sub-housing 11 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com