Automatic adjusting mechanism for distance between every two finger boards of two-layer platform of drilling workover rig

An automatic adjustment, two-story platform technology, applied in drilling equipment, drill pipes, drill pipes, etc., to achieve the effects of safe and reliable operation, lower operating costs, and accurate finger-beam spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

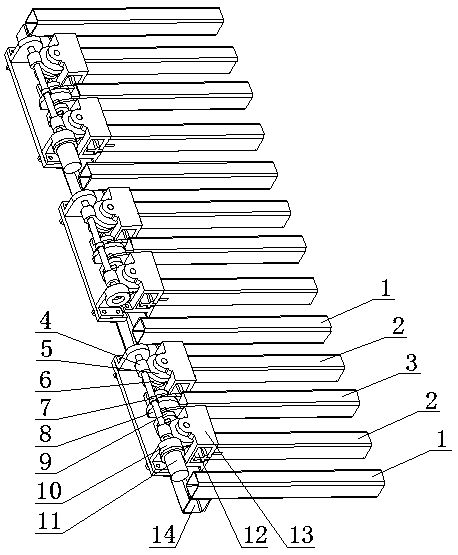

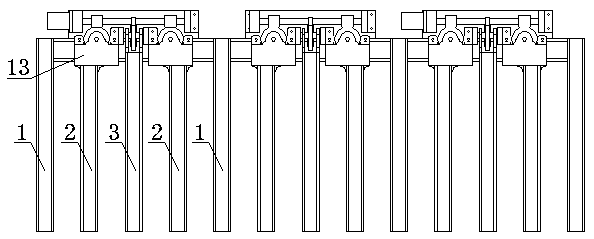

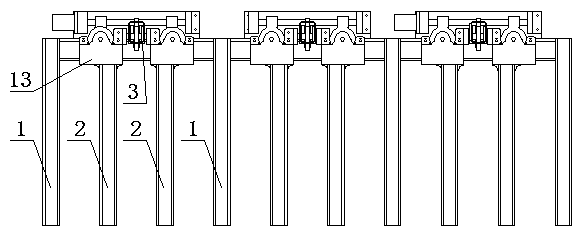

[0026] The principle and characteristics of the automatic adjustment mechanism for the distance between the fingers and beams of the second-floor platform of the drilling and workover rig will be further described below in conjunction with the accompanying drawings (see the attached Figure 1-8 ).

[0027] The automatic adjustment mechanism for the distance between the finger beams of the second floor platform of the drilling and workover rig is a finger beam unit of the second floor pipe rack of the workover rig, and the second floor pipe rack consists of two or more sets of finger beam units on the second floor rack (see attached Figure 7-8). It consists of fixed finger beam 1, sliding finger beam 2, flipping finger beam 3, worm screw 4, worm gear 5, gear A6, gear B7, gear C8, gear bearing seat 9, transmission shaft bearing seat 10, motor 11, rack 12, The sliding seat 13, the two-story platform longitudinal beam 14 and the drive shaft 15 are composed; the second-story pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com