Photovoltaic back membrane resistance testing instrument

A technology of resistance tester and back film, which is applied in the field of photovoltaic back film resistance tester, can solve the problems of limited insulation characteristics and inability to meet the insulation test, and achieve the effect of simple and reliable structure, convenient measurement and wide detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

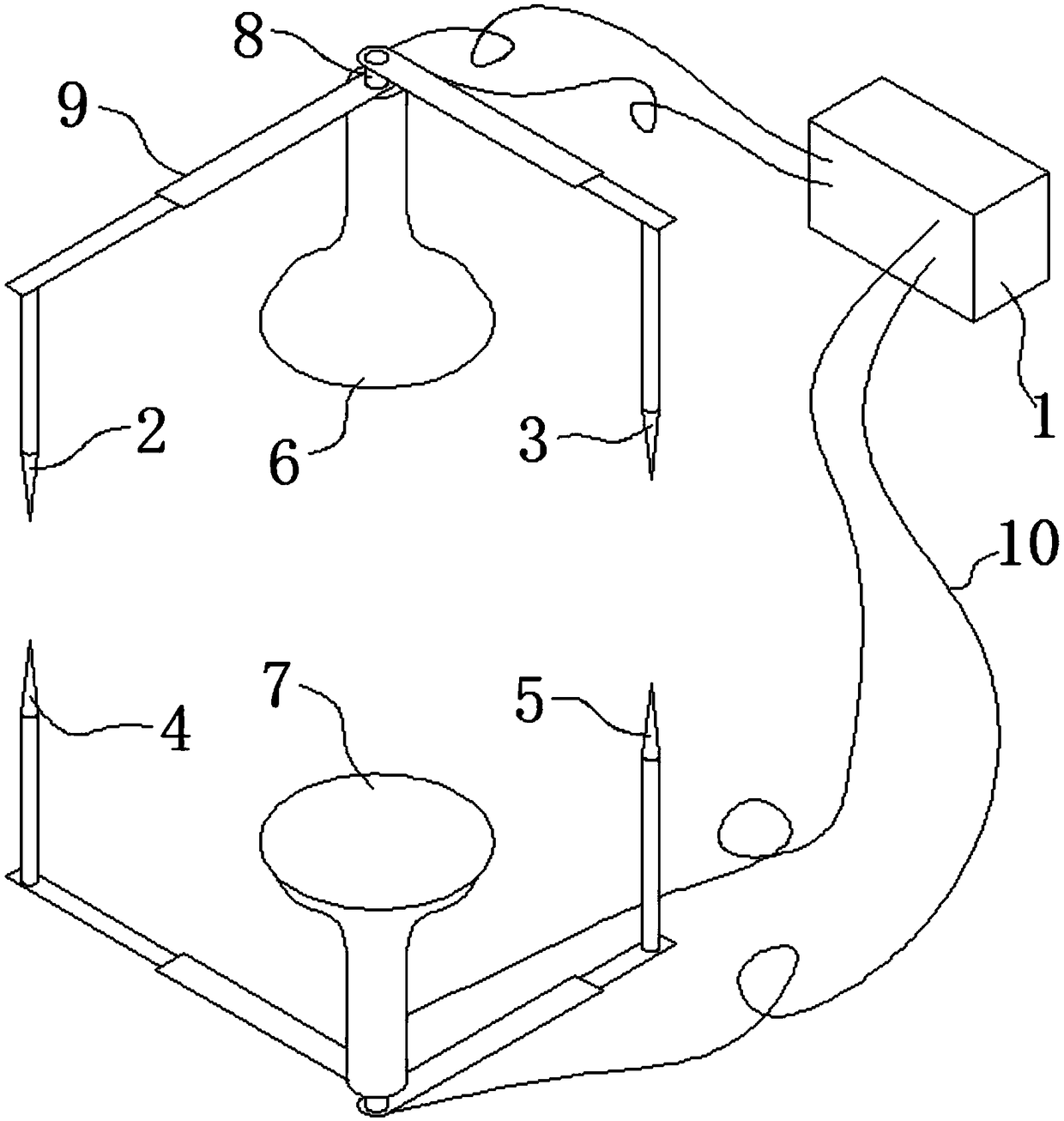

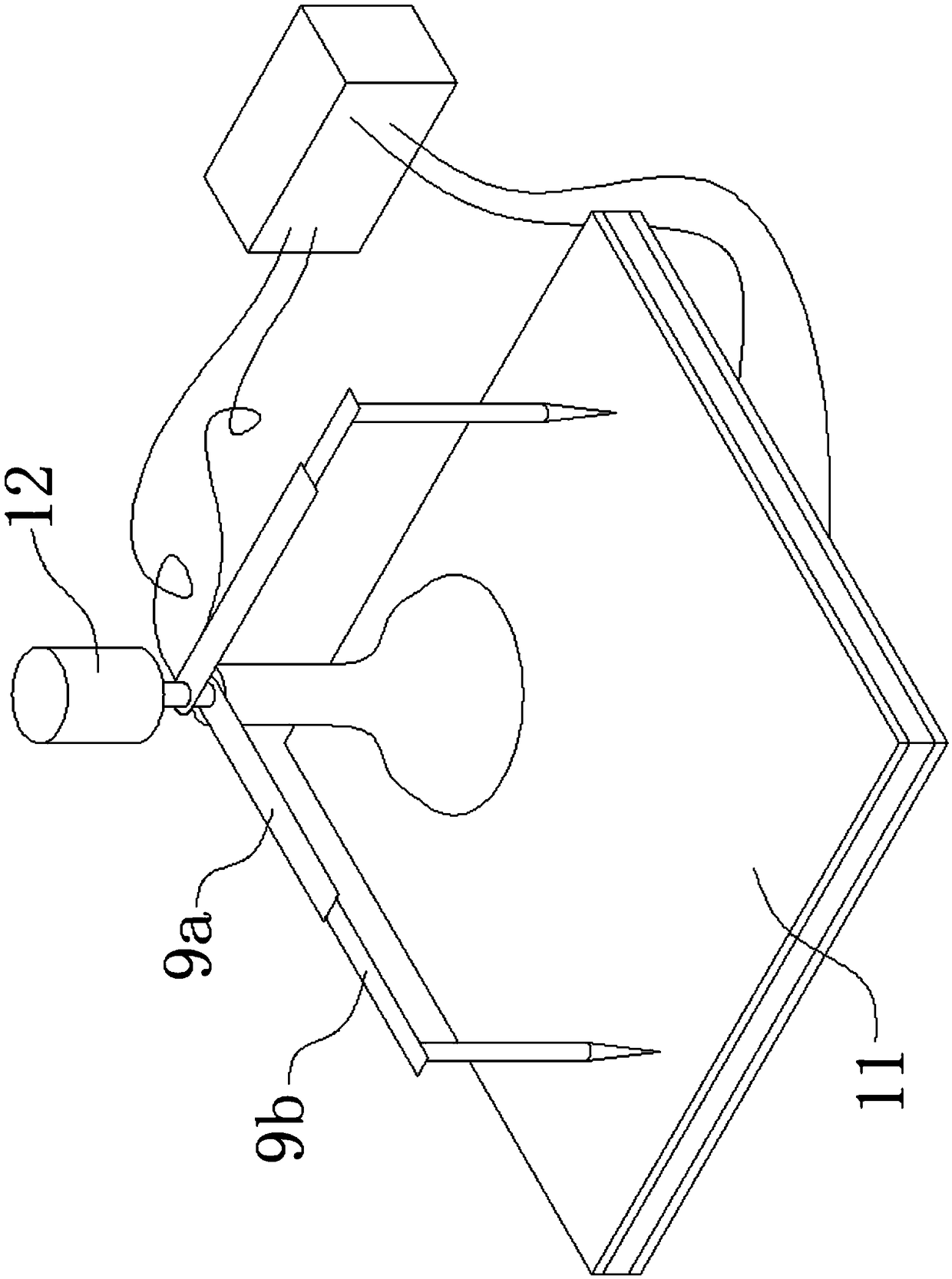

[0030] In order to achieve the purpose of the present invention, a kind of photovoltaic back film resistance tester comprises: resistance table box 1; The positive terminal 4 on the back and the negative terminal 5 on the back are connected to the resistance meter box 1 through wires 10 respectively; the connection mechanism is movably connected and mutually insulated. The front negative terminal 2 and the front positive terminal 3 are movably connected and insulated from each other. 4. Negative terminal 5 on the back.

[0031] The front negative terminal 2, the front positive terminal 3, the back positive terminal 4, and the back negative terminal 5 are connected to the resistance meter box 1 through four wires 10 in total. A battery is provided in the resistance meter box 1, and resistance is measured using Ohm's law.

[0032] The beneficial effect of ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com