High-precision indexing mechanism with temperature control function

A technology of temperature control and indexing mechanism, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., it can solve the problems that the frame is easily deformed, cannot work normally, and its own accuracy is difficult to guarantee, so as to improve the test efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

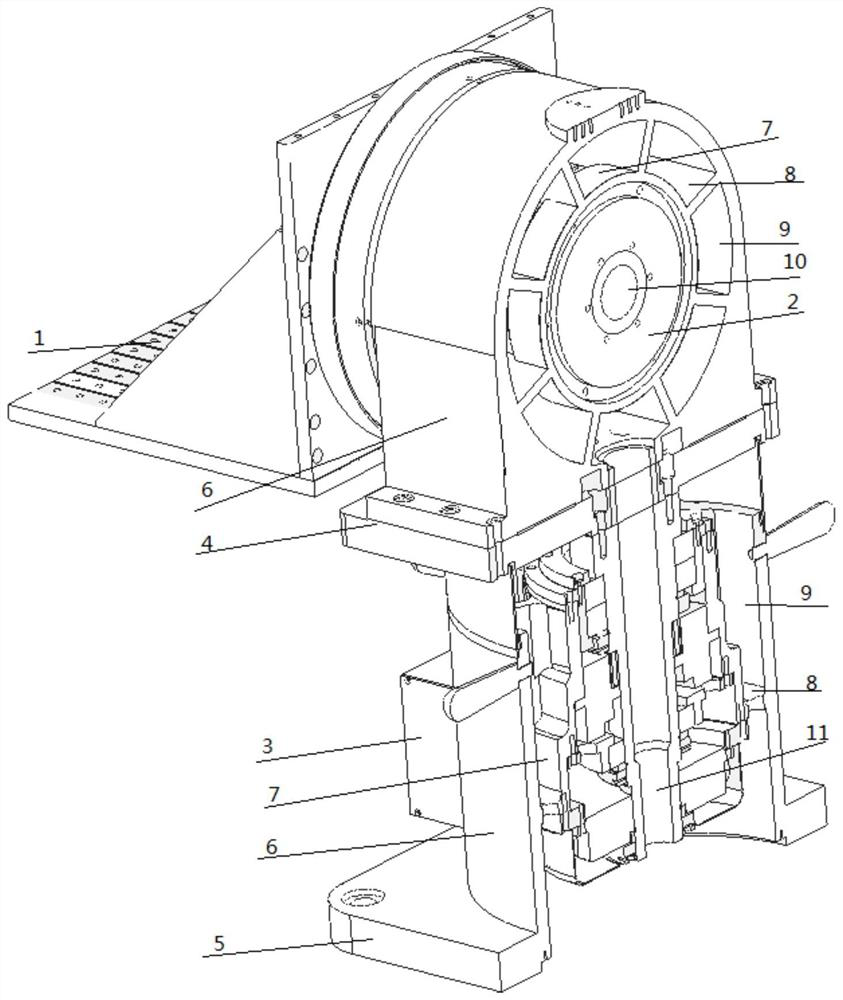

[0020] A high-precision indexing mechanism with temperature control function, including a horizontal axis 10 and a vertical axis 11, the horizontal axis 10 drives the worktable 1 to complete the rotation movement in the pitch direction; the vertical axis 11 drives the pitch base 4, and the pitch base 4 drives the worktable 1 Complete the rotational movement in the yaw direction, and make the normal of the worktable 1 point to any area of the sky through the horizontal axis 10 and the vertical axis 11. The whole device is installed on the yaw base 5 .

[0021] The sensor 2 is installed on the outer periphery of the horizontal axis 10. When the outdoor temperature is lower than the allowable working temperature of the sensor 2, the temperature control system 3 is turned on, and the temperature control system 3 respectively controls the first-stage temperature control system 6 on the yaw base 5 and the temperature control system on the yaw base 5. The second-level temperature c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com