Semiconductor device and preparation method thereof

A manufacturing method and semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of high source-drain contact resistance, etc., and achieve the effects of small contact resistance, reduced contact resistance, and good alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] The fabrication process of semiconductor devices includes:

[0060] A germanium-based semiconductor preparation 10 is provided, the semiconductor preparation 10 includes a germanium substrate and a source region 11 and a drain region 12 arranged in the germanium substrate, figure 1 Only the source region 11 is shown in the figure, and the drain region 12 is the same as the source region 11, both of which are doped with N-type impurity P;

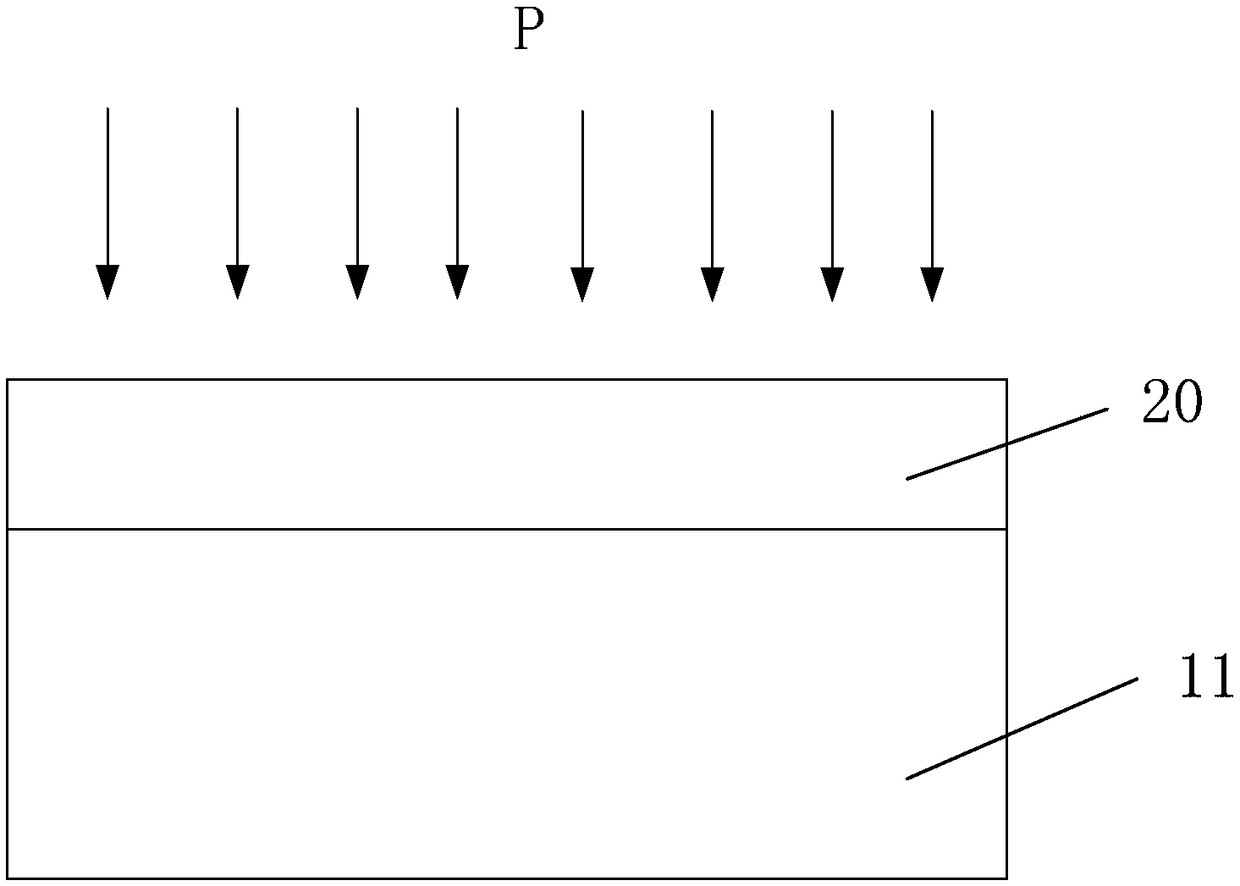

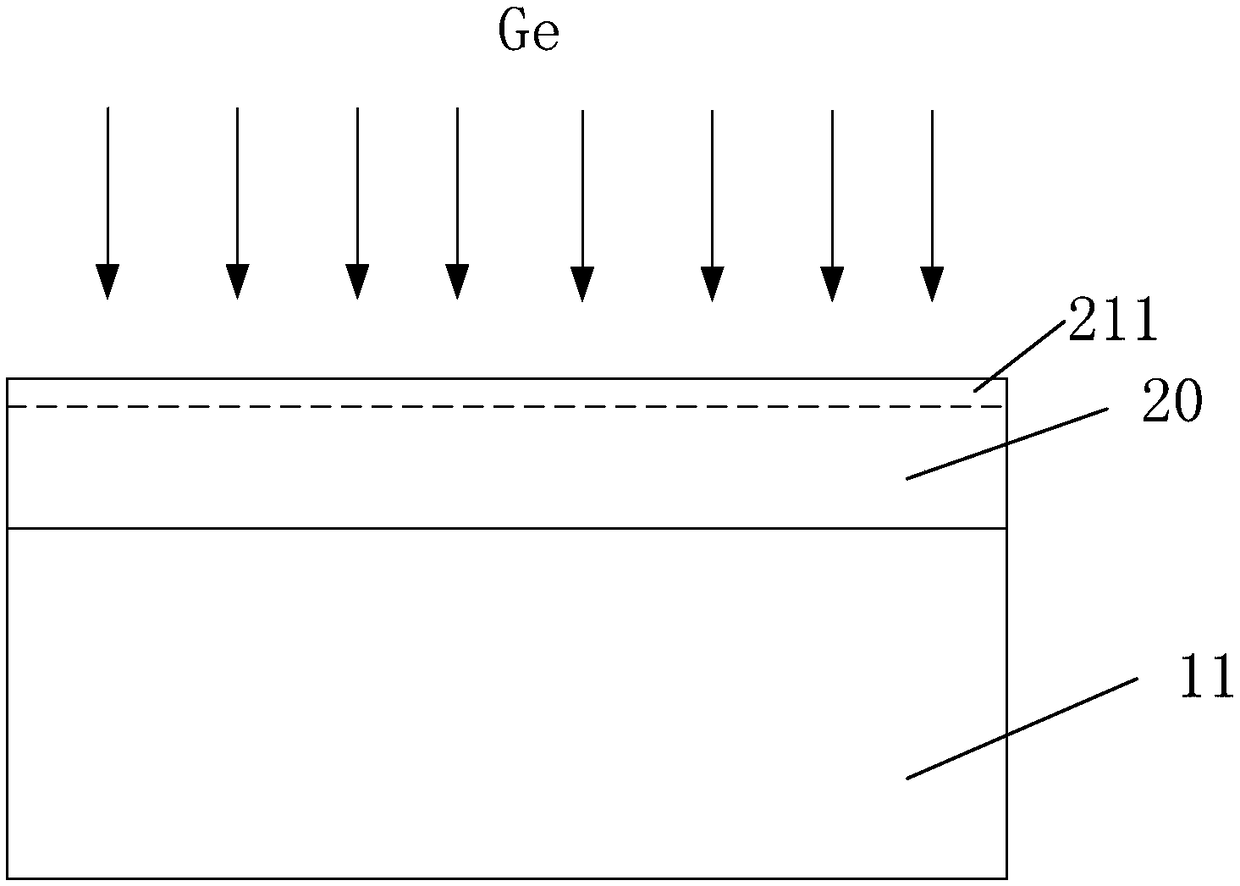

[0061] Pre-epitaxial layers 20 are respectively arranged on the exposed surfaces of the source region 11 and the drain region 12, and each of the above-mentioned pre-epitaxial layers 20 includes a base material and a second N-type impurity doped in the base material, and the base material is Silicon, the second N-type impurity is P, and the doping concentration of the above-mentioned second N-type impurity is 1.0×10 20 cm -3 ~9.0×10 21 cm -3 between, figure 2 It just shows that a pre-epitaxial layer 20 is provided on the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com