Electric-resistance-welded steel pipe for boiler having excellent stress corrosion cracking resistance, and method for manufacturing same

A technology for stress corrosion resistant and electric resistance welded steel pipes, applied in the field of electric resistance welded steel pipes, can solve problems such as pipe bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

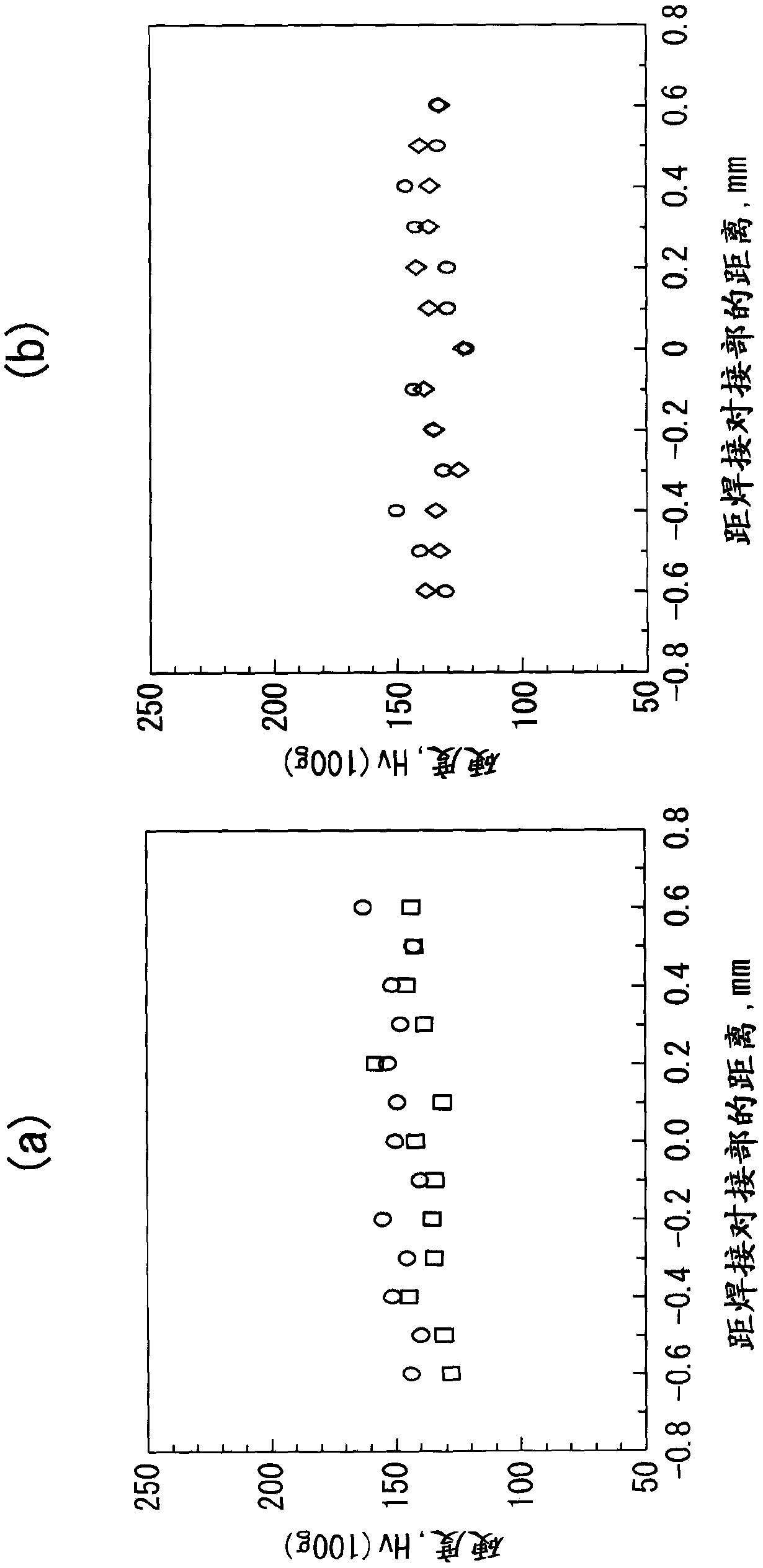

[0180] Next, the effects of the present invention were demonstrated by comparing the characteristics of the examples of the present invention (invention steel pipe) and the characteristics of comparative examples (comparison steel pipes). The conditions used in producing the inventive steel pipe are examples of conditions adopted for confirming the practicability and effects of the present invention, and therefore the present invention is not limited by these examples of conditions. In addition, the present invention can adopt various conditions without departing from the gist and achieving the purpose.

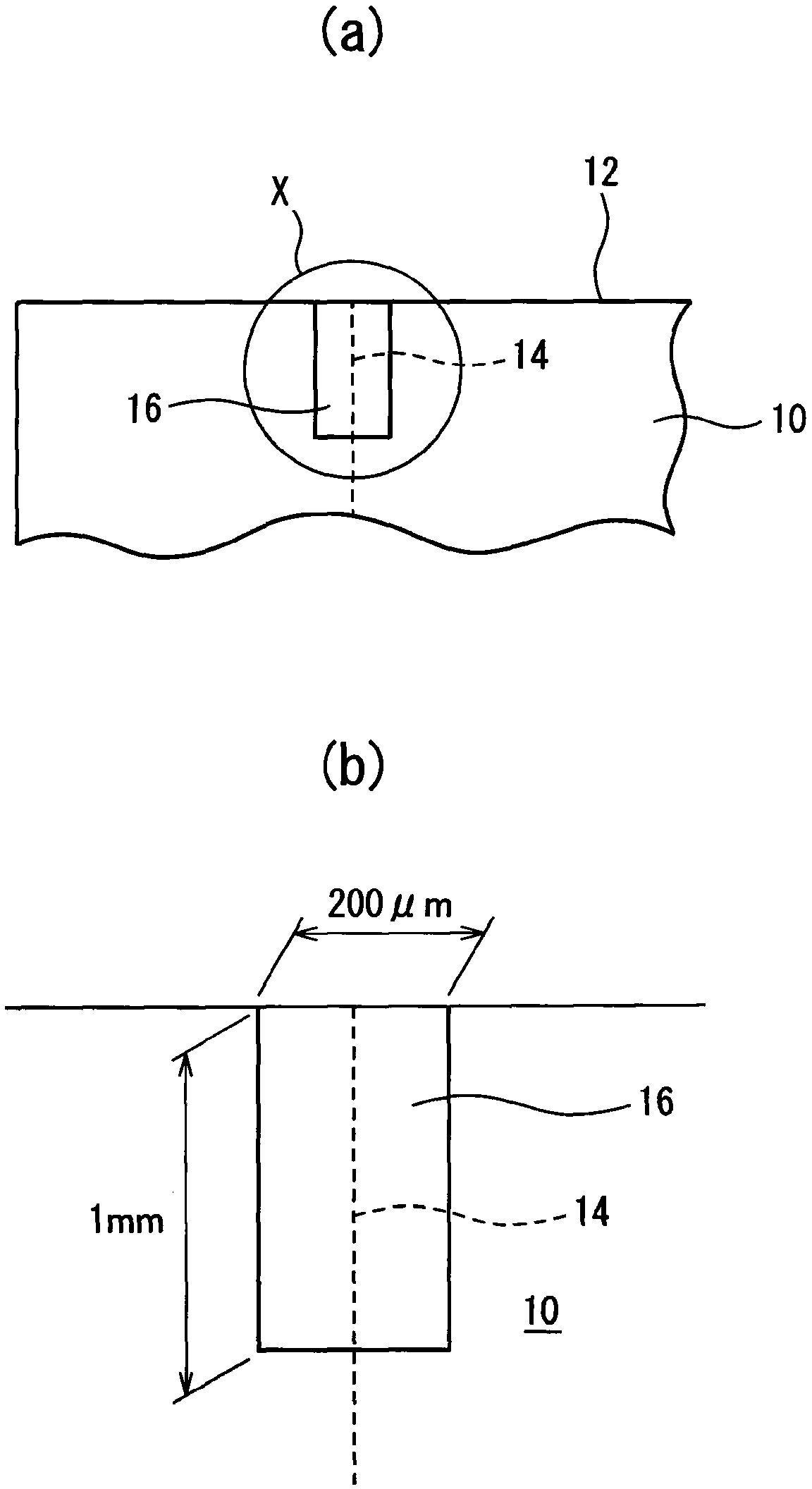

[0181] [Manufacture of electric resistance welded steel pipe]

[0182] Each steel strip shown in Table 1 having 20 kinds of composition was molded. In addition, the calculation method of Ac3 point about each steel strip is described in the lower part of Table 1 at the same time. In addition, in Table 1, a blank part means not containing that element.

[0183] Table 1

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com