Extrusion-cutting device for vertical thick-wall sprue with high solid phase and semi-solid state

A thick-wall gate and semi-solid technology, which is applied in the field of high-solid semi-solid die-casting, can solve the problems that the extrusion and cutting device cannot meet the extrusion and cutting requirements, and achieve the effect of solving the problem of dust environmental pollution, high product efficiency and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated below with reference to the drawings.

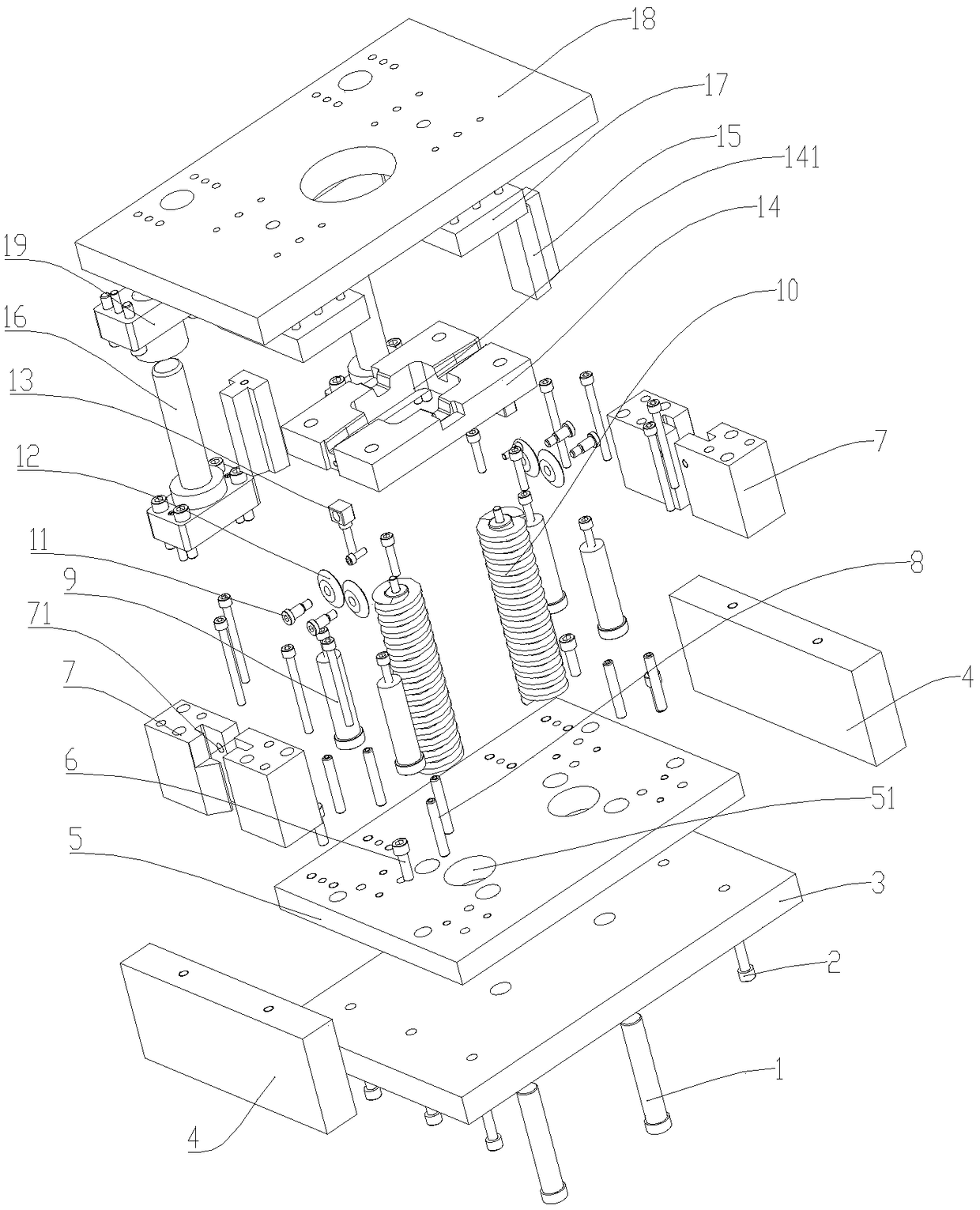

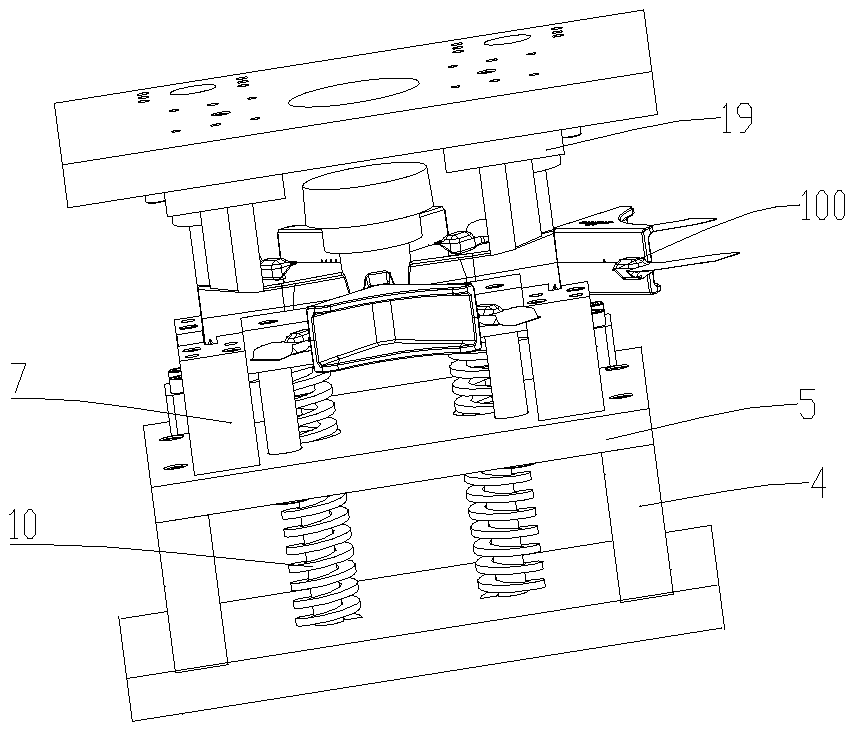

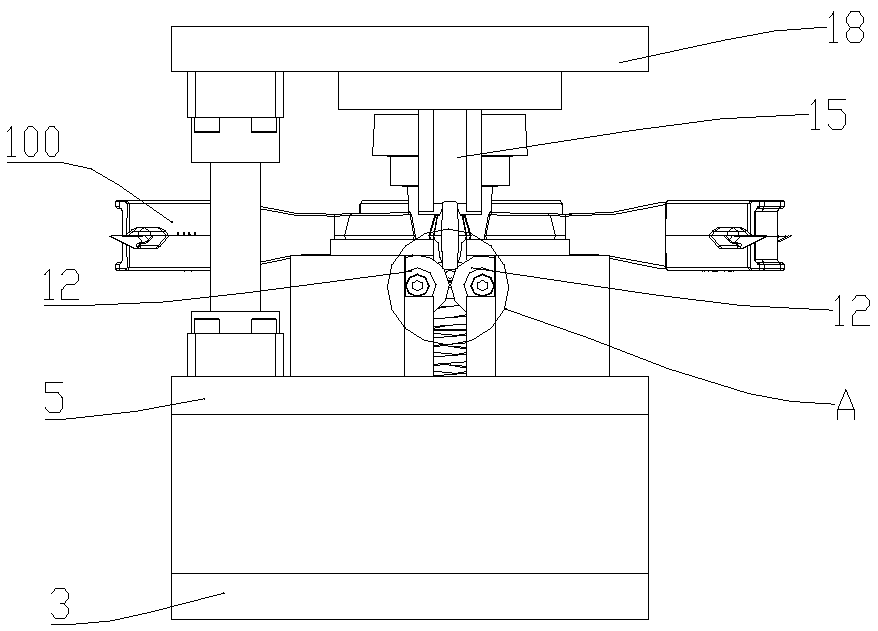

[0021] See Figure 1 to Figure 4 In this embodiment, the high-solid-phase semi-solid vertical thick-wall gate extrusion device includes: an upper mold assembly and a lower mold assembly, which are clamped and fixed between the upper mold assembly and the lower mold assembly The workpiece 100 squeezes and cuts the gate of the workpiece.

[0022] See again figure 1 , The upper mold assembly includes: an upper template 18, a fixed plate 17 connected to the upper template 18, and a punch 15 connected to the fixed plate 17; the fixed plate 17 is connected to the upper template 18 by screws There are two fixed plates 17 which are connected to the upper template 18 in a linear distribution. A punch 15 is connected to the two fixed plates 17 respectively. The punch 15 is used to push the workpiece 100 down when the workpiece 100 is pressed down.

[0023] Further, the lower die assembly includes:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com