Method and device for controlling humidity of belt-shape material in pringting machine

A printing machine and belt control technology, which is applied to the general parts of printing machinery, printing machines, rotary printing machines, etc., can solve problems such as disturbed positioning, difficult calibration, and unsteady width of paper tapes, etc., to achieve increased functionality and rapid The effect of the final alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

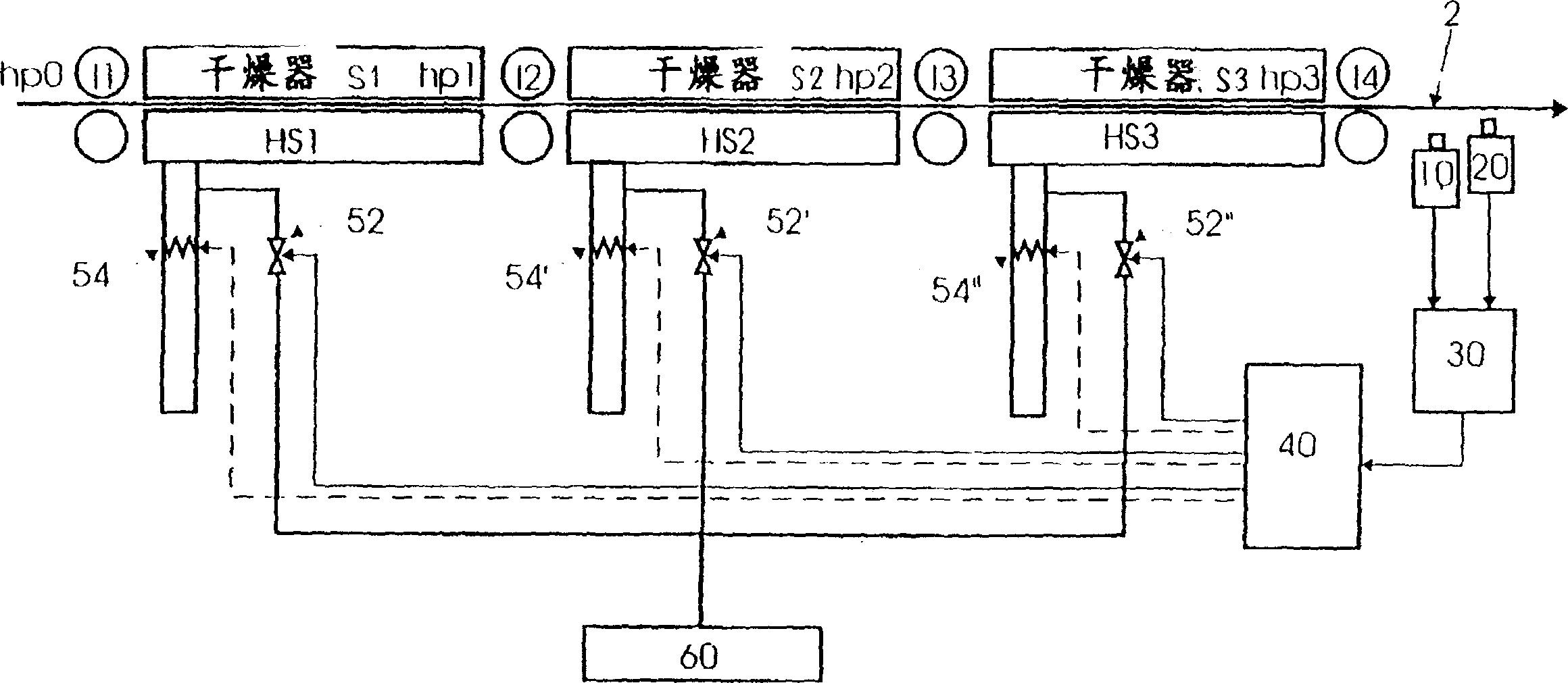

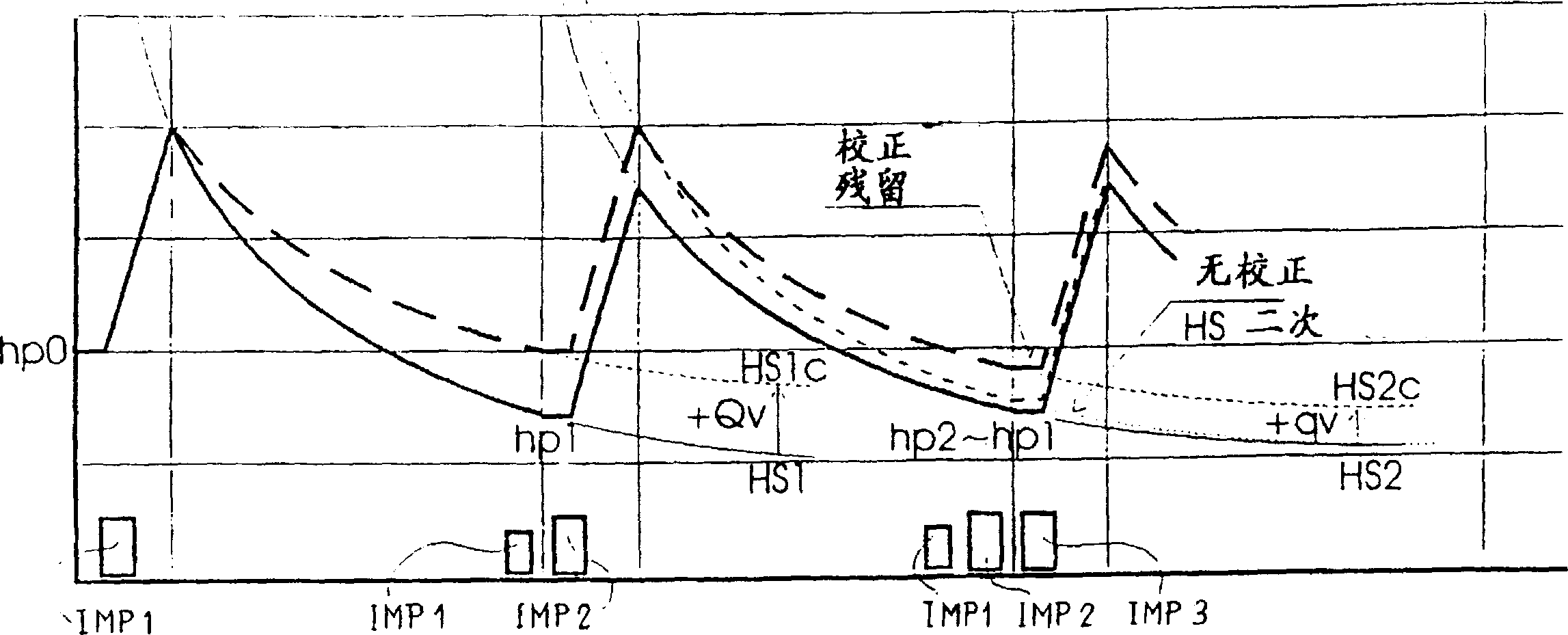

[0043] exist figure 1 The upper part of , schematically represents a printing press in which a color image is to be printed on a web (eg paper or cardboard) 2 . The gravure press, for example, consists of four printing groups: the first group I1 prints yellow; the second group I2 prints red; the third group I3 prints blue and the last group I4 prints black so that The final image is finished with contrasting shades of color. With offset printing, the colors are printed in reverse order, from darker to lighter. In this machine, the previous color must be completely dry before the next color is printed to avoid mixing or smudging at all. In addition, the oil applied by the first printing group wets the web momentarily, which widens the web and it is best to allow it to return to its original size before going to the next printing. Thus, in the illustrated embodiment, the web entering the machine has an initial humidity of hp0 and a humidity of hp1 at the exit of the first pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com