Vacuum adsorption clamp

A vacuum adsorption and fixture technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of uneven force on sheet workpieces, affecting the quality of sheet workpieces, and low adsorption force, so as to improve processing accuracy and service life , Uniform adsorption force, improve the effect of adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

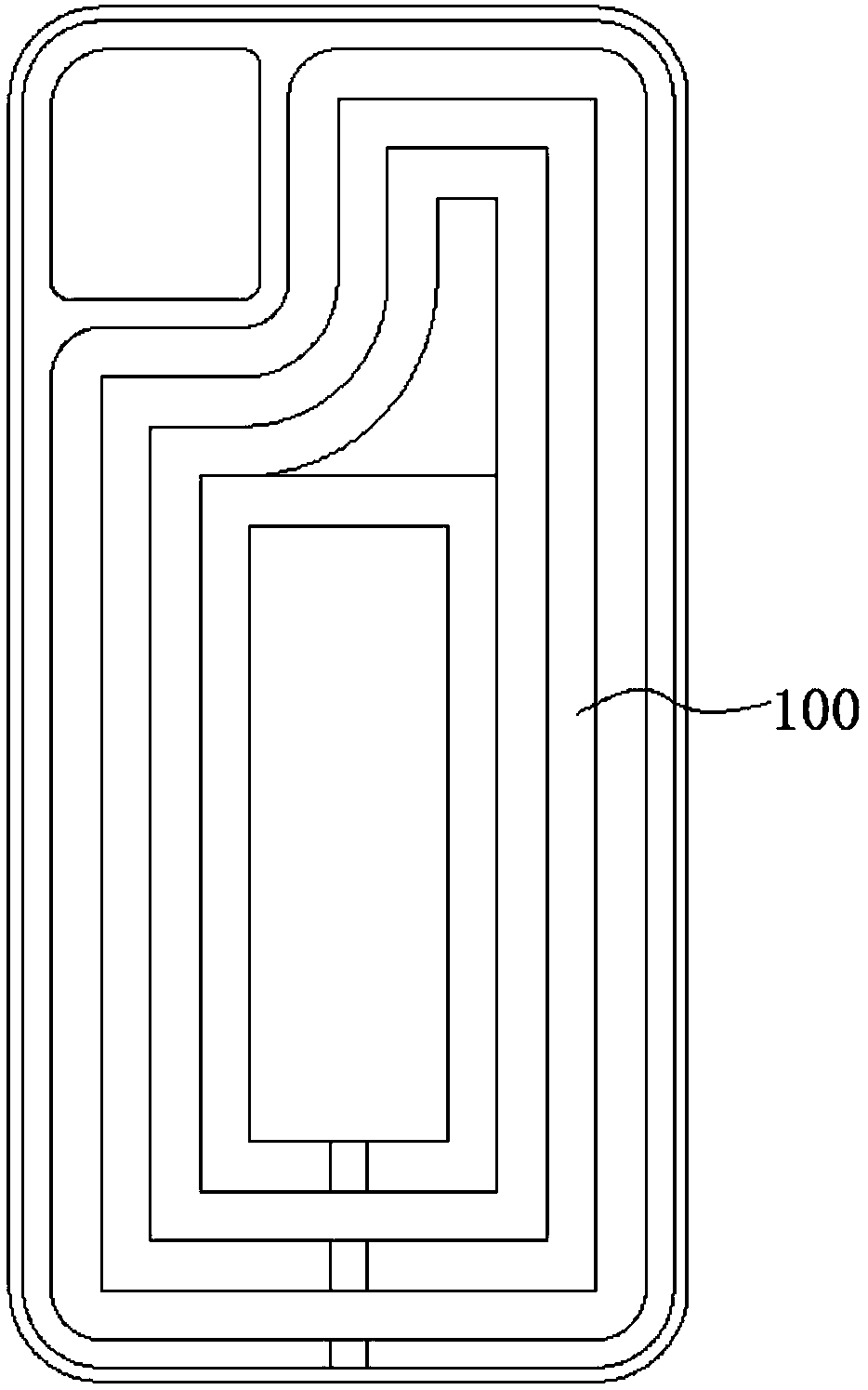

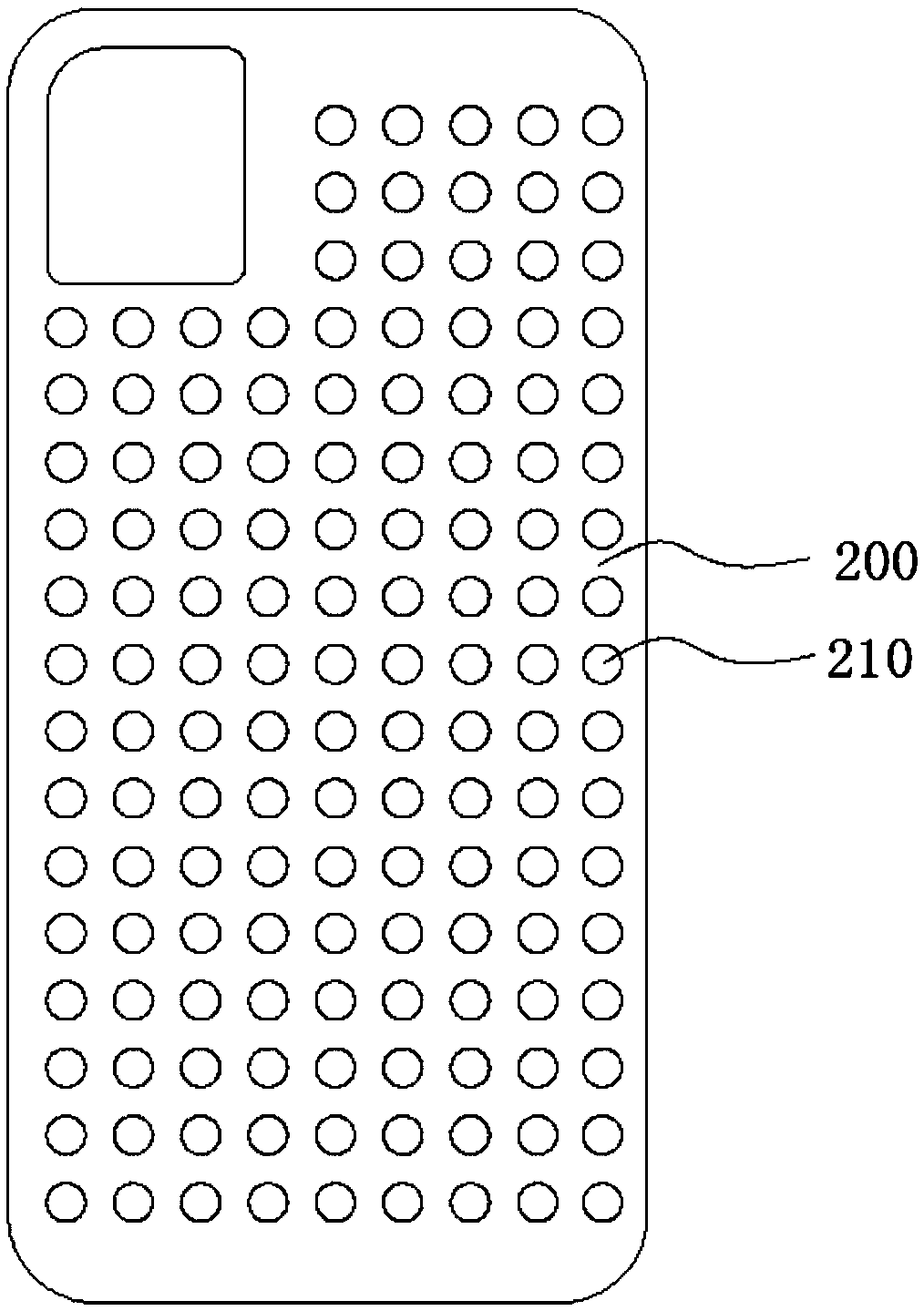

[0046] See Figure 4 and Figure 5 As shown, the vacuum adsorption fixture of the present invention is schematically shown, which includes a fixed plate 10 and a workpiece adsorption block 20 above the fixed plate 10. The upper surface of the workpiece adsorption block 20 in this embodiment is used to absorb the workpiece to be processed. For example, sheet workpieces such as mobile phone screen glass or shell, the upper surface of the workpiece adsorption block 20 is provided with a number of first air holes 21 arranged in a ring structure near the outer edge of the workpiece, and is located in the ring structure surrounded by the first air holes 21. The inner side of the fixed plate 10 is provided with a number of second air holes 22 that run through the upper and lower surfaces of the workpiece adsorption block 20. The inside of the fixed plate 10 is provided with a sealed cavity 11 communicated with the second air holes 22, and the outer side of the fixed plate 10 is provi...

Embodiment 2

[0054] See Figure 8 and Figure 9 As shown, the difference between the workpiece adsorption block 20 in this embodiment and the first embodiment is that the lower surface of the workpiece adsorption block 20 is provided with a groove 26 that is opposite to and communicated with the sealed cavity 11, and the groove 26 The side wall is sealed and connected to the side wall of the sealed cavity 11, and the second air hole 22 penetrates from the upper surface of the workpiece adsorption block 20 to the groove 26, so as to reduce the overall weight of the workpiece adsorption block 20; one side of the fixed plate 10 is provided with a depression 13 , The air extraction hole 12 is located in the depression 13, so as to shorten the length of the air extraction hole 12, so as to improve the processing accuracy of the air extraction hole 12, improve the processing efficiency and reduce the processing cost.

[0055] Further, the workpiece adsorption block 20 is provided with an annula...

Embodiment 3

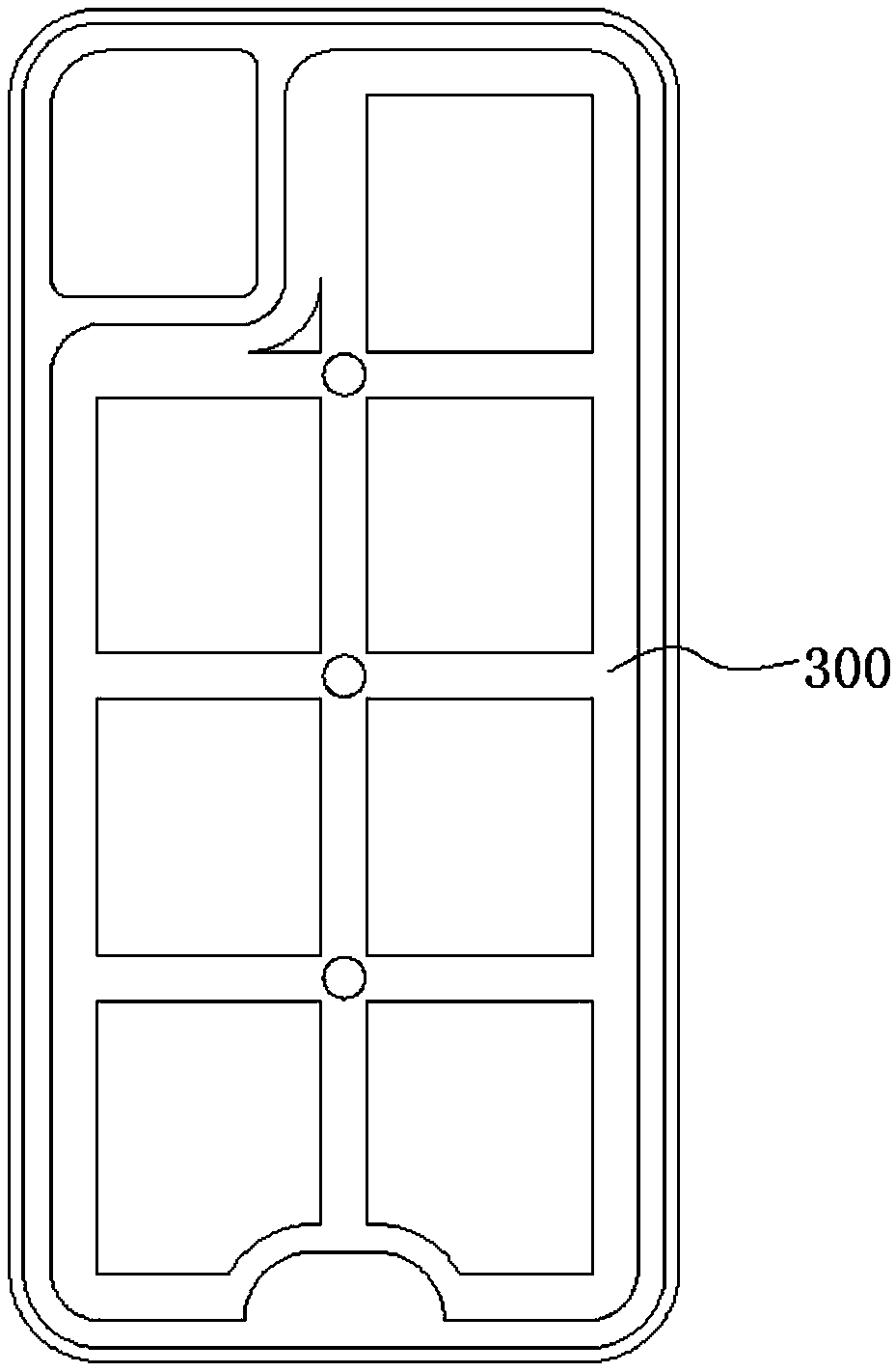

[0064] See Figure 10 , Figure 11 and Figure 12 As shown, the difference between the vacuum adsorption fixture in this embodiment and the second embodiment is that a plurality of sealed cavities 11 are arranged side by side inside the fixed plate 10, and a plurality of sealing cavities 11 are provided on the lower surface of the workpiece adsorption block 20. The groove 26 of position one-to-one correspondence (as Figure 12 shown in ), each groove 26 communicates with the sealed cavity 11 respectively, the side wall of the groove 26 is sealed and connected with the side wall of the sealed cavity 11 corresponding to it, and each groove 26 communicates with the second air hole 22 respectively; at the same time, The outside of fixed plate is provided with a plurality of air extraction holes 12 (as Figure 11 shown in ), each pumping hole 12 is connected to a vacuum pump, and each pumping hole 12 communicates with each sealed cavity 11 respectively.

[0065] In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com