Hardware system of printer

A hardware system and printer technology, applied in printing devices, printing, etc., can solve the problems of inability to fade, withstand the test of time, and long-term preservation of text, and achieve good printing results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] Explanation of terms:

[0043] MCU: Micro Controller Unit (micro control unit), also known as single-chip microcomputer (Single Chip Microcomputer) or single-chip microcomputer.

[0044] SDRAM: Synchronous Dynamic Random Access Memory (Synchronous Dynamic Random Access Memory)

[0045] LCD: Liquid Crystal Display (liquid crystal display)

[0046] LCD display parameters: CLOCK: pixel clock;

[0047] VS: Vertical Sync (horizontal synchronization)

[0048] HS: Horizontal Sync (vertical synchronization)

[0049] DE: Data Enable (data valid enable)

[0050] DATA: display data

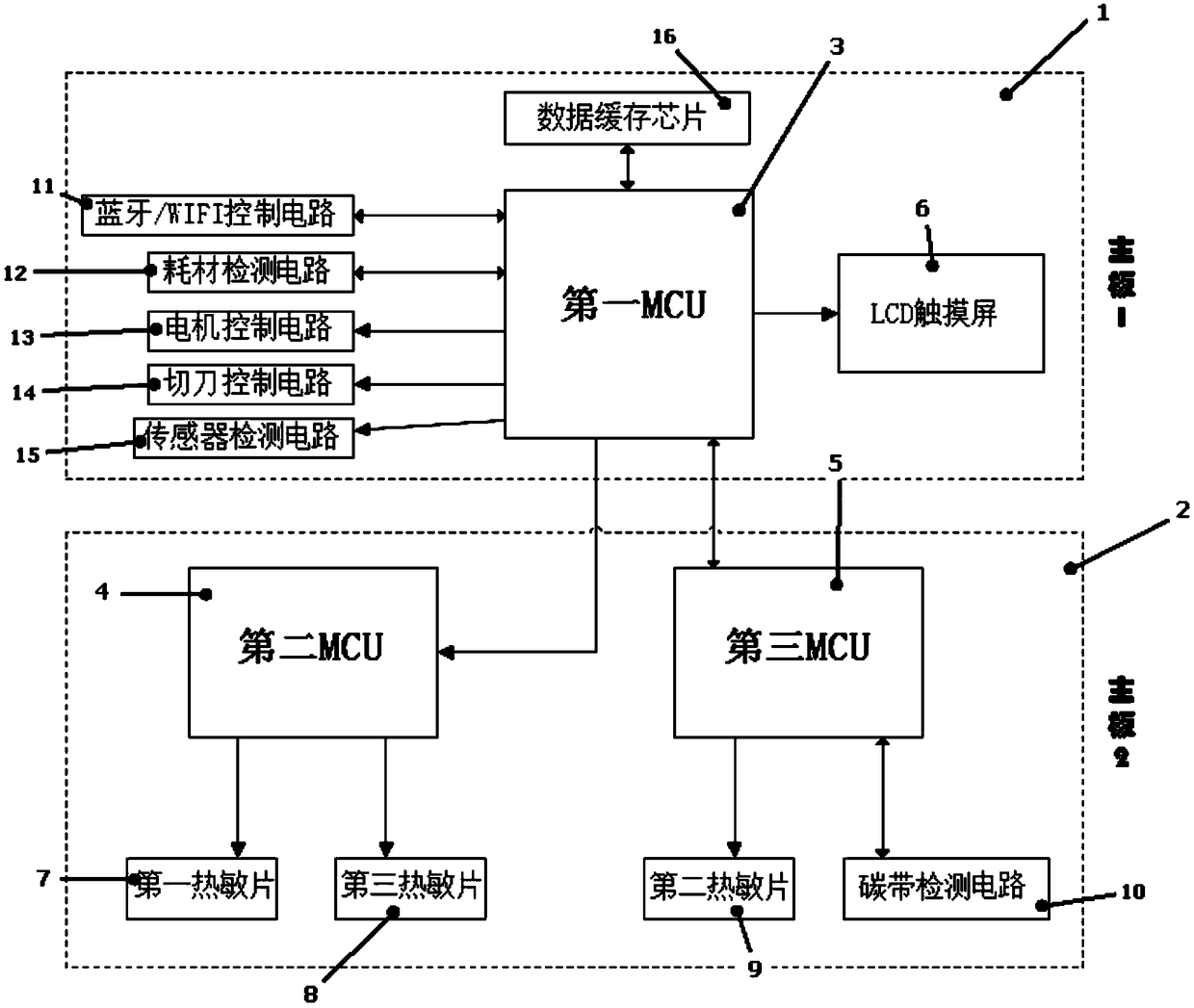

[0051] Such as figure 1 As shown, the present invention provides a hardware system of a printer, including a first MCU 3, a second MCU 4, a third MCU 5, a data cache chip 16, a wireless control circuit 11, a consumable detection circuit 12, a motor control circuit 13, a cutting Knife control circuit 14, sensor detection circuit 15, touch screen 6, first thermal sheet 7, second thermal sheet 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com