Agricultural plastic polyethylene mulching film

An agricultural mulch, polyethylene technology, applied in application, plant protection, horticulture, etc., can solve the problems of white pollution, the physical and mechanical strength of polyethylene mulch film, and seeds cannot take root, etc., and achieve the effect of improving production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

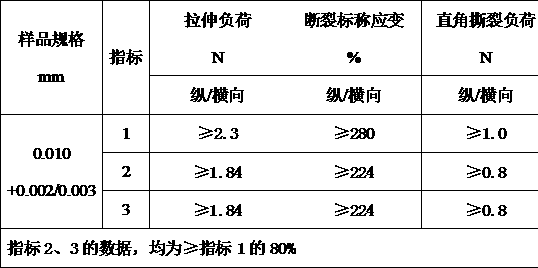

Image

Examples

Embodiment 1

[0034] Produced by conventional mulch production process, the raw materials are proportioned by weight, 86 parts of linear polyethylene, 10 parts of metallocene polyethylene, 2 parts of anti-aging masterbatch for Demeron mulch, 0.5 part of open masterbatch for Demeron mulch; Anti-aging masterbatch for Demeiron mulching film: 86 parts of polyethylene, 14 parts of light stabilizer 944, 3 parts of antioxidant 1010, 0.5 part of zinc oxide, 0.5 part of zinc stearate; special opening masterbatch for Demeuron mulching film is: The particle size is 20,000 mesh calcium carbonate / silicon dioxide 80 parts, wax 10 parts, polyethylene 7 parts.

Embodiment 2

[0036] Produced by conventional mulch production process, the raw materials are proportioned by weight, 90 parts of linear polyethylene, 14 parts of metallocene polyethylene, 3 parts of anti-aging masterbatch for Demeron mulch, 3 parts of open masterbatch for Demeron mulch; Anti-aging masterbatch for Demeiron plastic film: 90 parts of polyethylene, 20 parts of light stabilizer 944, 5 parts of antioxidant 1010, 1 part of zinc oxide, and 1 part of zinc stearate; special opening masterbatch for Demeiron plastic film is: The particle size is 20,000 mesh calcium carbonate / silicon dioxide 90 parts, wax 15 parts, polyethylene 10 parts.

Embodiment 3

[0038] Produced by conventional mulch production process, the raw materials are proportioned by weight, 88 parts of linear polyethylene, 12 parts of metallocene polyethylene, 2.5 parts of anti-aging masterbatch for Demeron mulch, 2 parts of open masterbatch for Demeron mulch; Anti-aging masterbatch specially used for Demeron mulch film: 88 parts of polyethylene, 18 parts of light stabilizer 944, 4 parts of antioxidant 1010, 0.75 part of zinc oxide, 0.75 part of zinc stearate; special opening masterbatch of Demeron mulch film is: The particle size is 20,000 mesh calcium carbonate / silicon dioxide 85 parts, wax 12 parts, polyethylene 8 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com