Wall surface installing assembly of wood protection wall board and installing method of wall surface installing assembly

A technology for installing components and wall panels, which is used in the processing of building materials, covering/lining, construction, etc., which can solve the problem that the upper lock and the lower lock are difficult to maintain horizontally, the wall panels are prone to tilt, and the wall panels are spliced together. Gap and other problems, to achieve good decoration and protection, simple and ingenious structure, good installation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0050] (A) Cut wooden wall panels, wooden wall panels include: longitudinal inclined wall panels, transverse inclined wall panels, horizontal wall panels, longitudinal inner wall panels and longitudinal outer wall panels, of which longitudinal inclined wall panels , one side of the horizontal slope wall panel is a slope (such as Figure 14 shown);

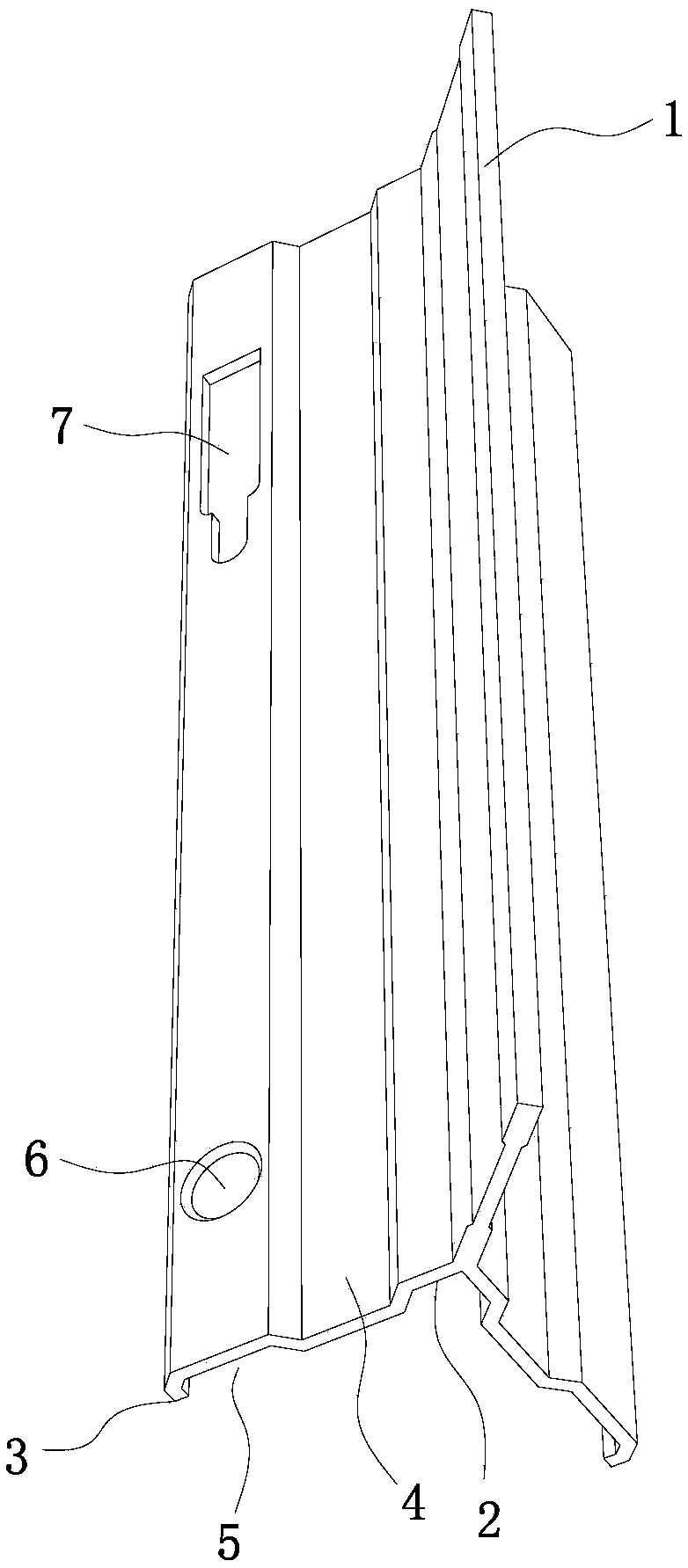

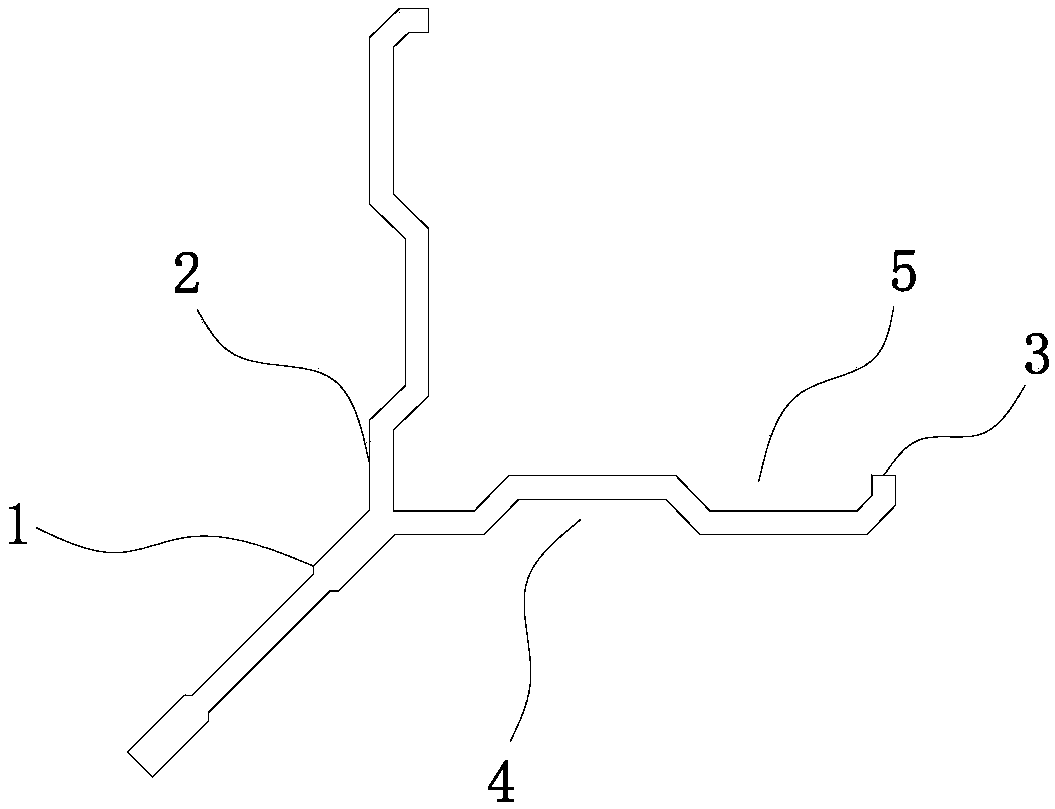

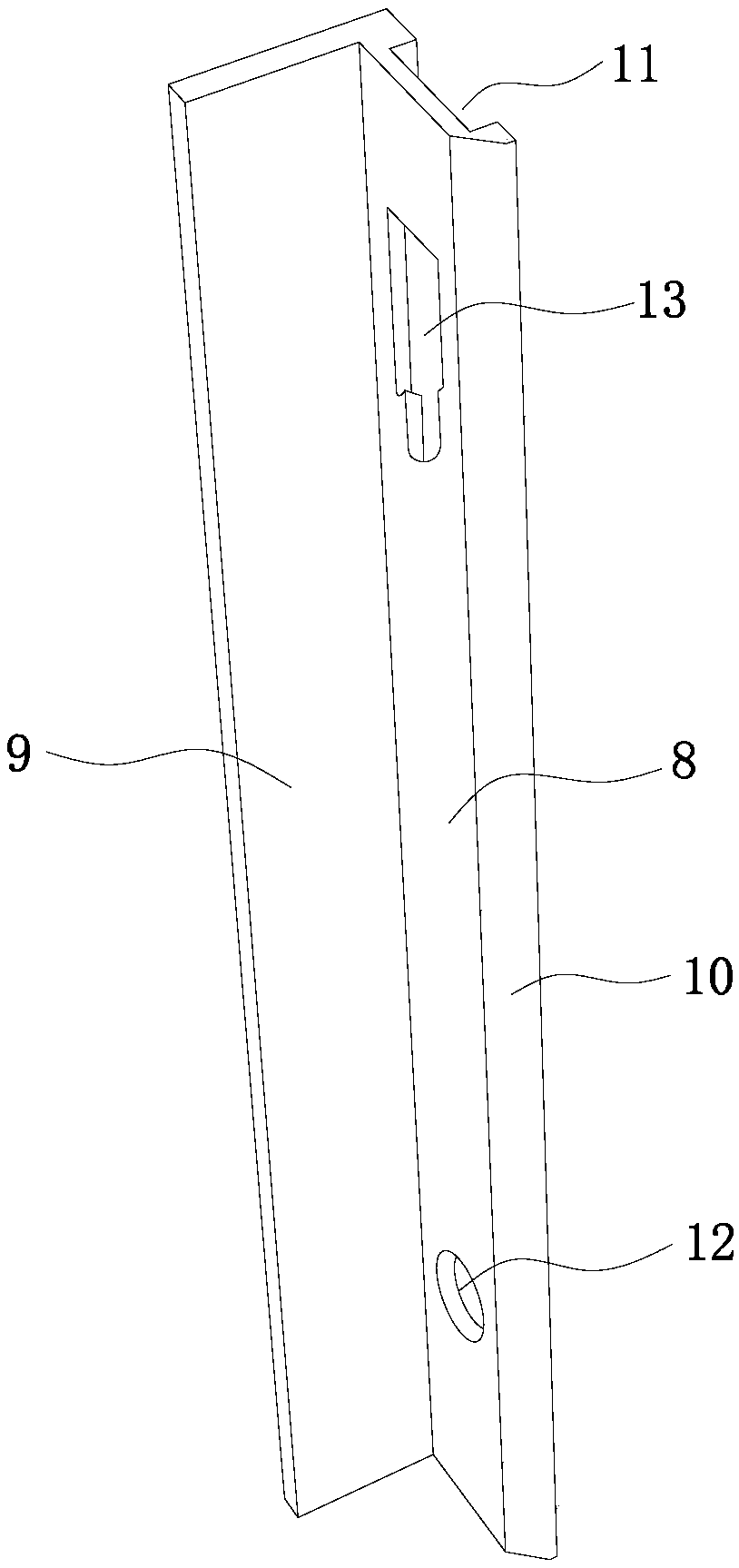

[0051] (B) Take an outer corner connector of the wall panel (such as figure 1 , figure 2 shown) and a wall panel inner corner connector (such as image 3 , Figure 4 shown); the outer corner connector of the wall panel includes a right-angle piece and an oblique partition 1, the right-angle piece is formed by connecting two partitions 2 perpendicular to each other, and the oblique partition is fixed at the outer corner between the two partitions , the angle between the inclined partition and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap