Automatic gear locking method and system of electric vehicle

An electric vehicle and automatic technology, applied in multi-gear ratio transmissions, transmission components, vehicle parts, etc., can solve problems such as aggravating the wear of transmission parts and affecting driving comfort, and achieves high feasibility, low implementation cost, and short cycle time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0037] In order to solve the problem of climbing and shifting cycles of Automated Manual Transmission (AMT) models, the existing AMT models are mainly solved by adding a manual lock function. When the manual lock is turned on, AMT gear shifting is prohibited, that is, when climbing a steep slope, you can manually lock it in the first gear, and let it climb in the first gear all the time.

[0038] However, this method has certain limitations, that is, the gear needs to be manually locked before climbing, and the gear needs to be released when the road is flat, which increases the driving intensity of the driver.

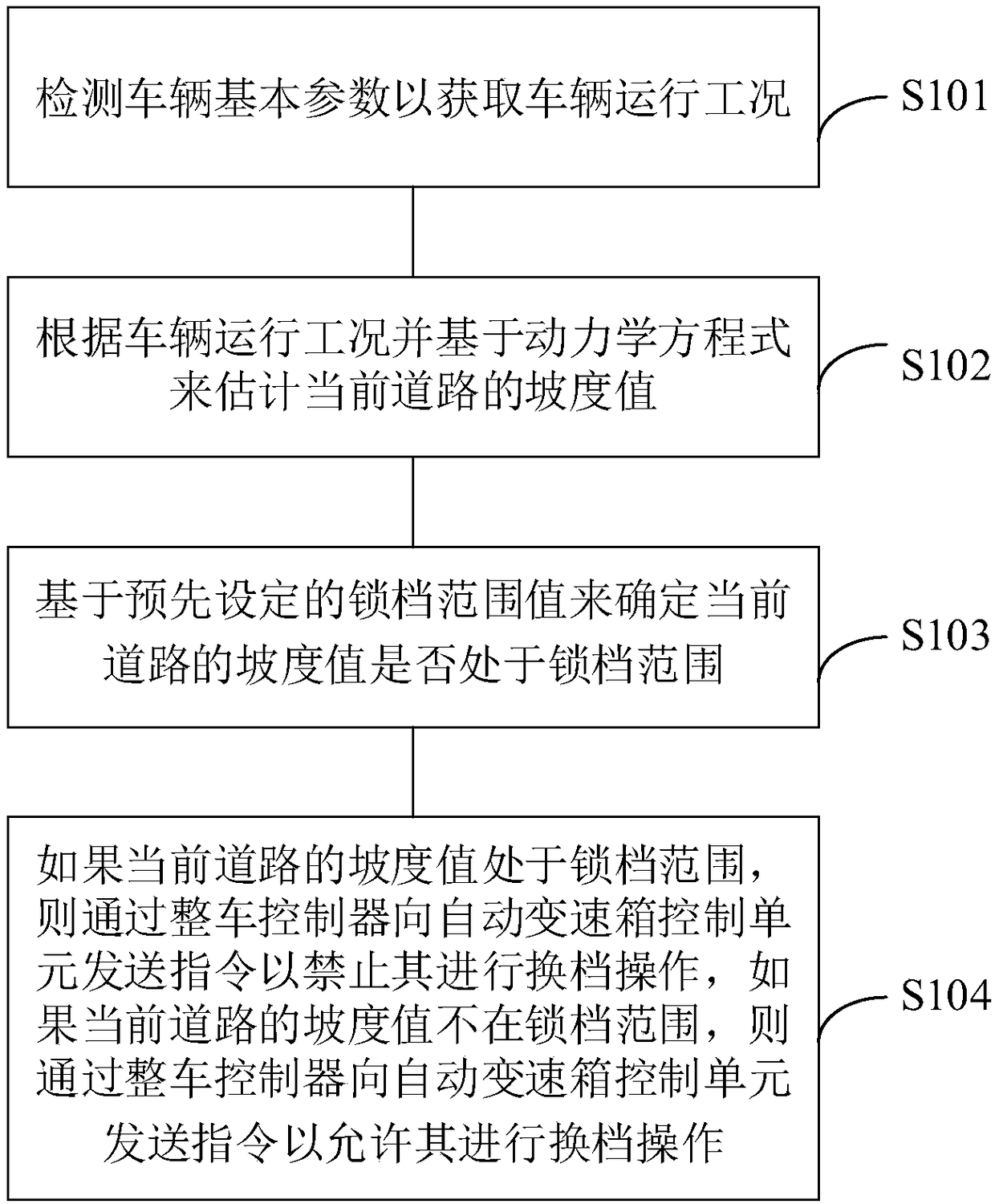

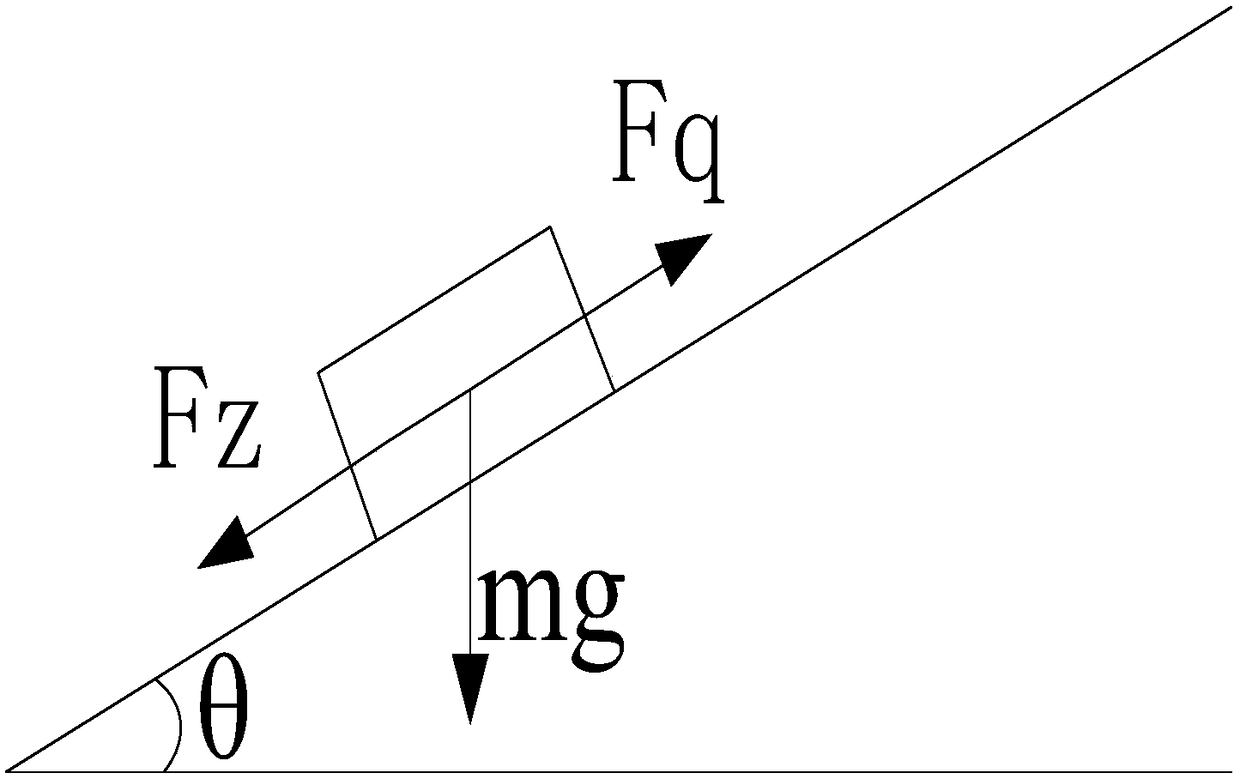

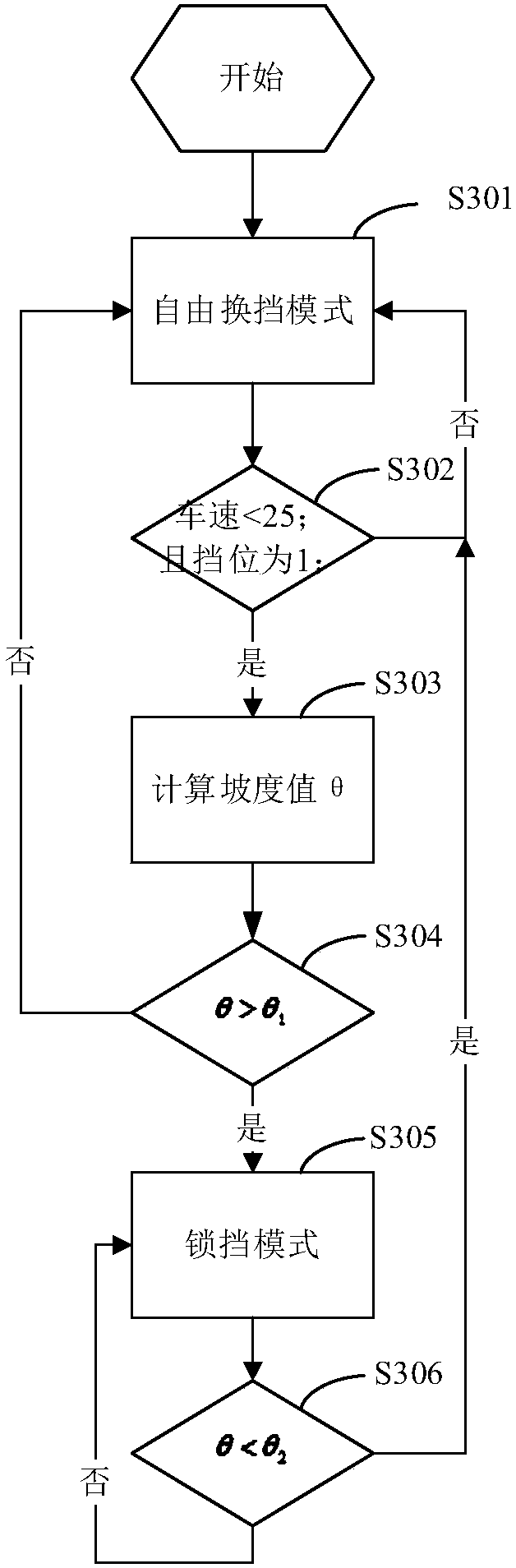

[0039] Therefore, the present invention provides a method and system for automatic gear locking of electric vehicles. The road gradien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com