Fire hose drying device with direct combustion type solution dehumidification and heat recycling

A technology of heat recovery device and fire hose, which is applied in the direction of progressive dryer, drying gas arrangement, drying room/container, etc. It can solve the problems of moldy and rot, unable to dry, fire hose cannot be dried in time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

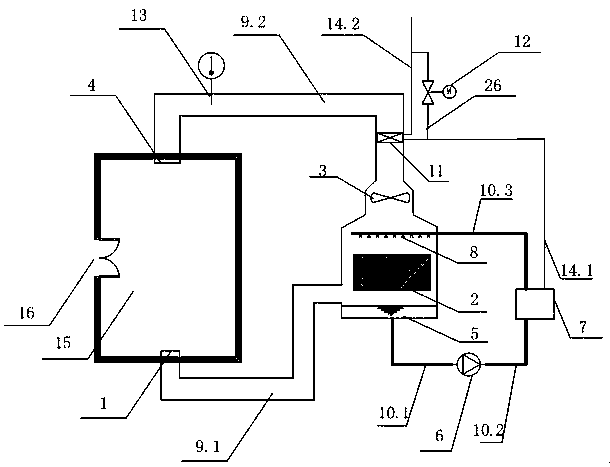

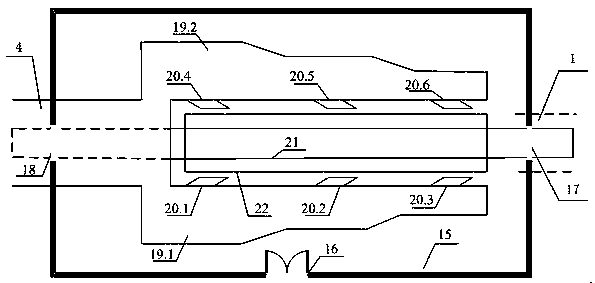

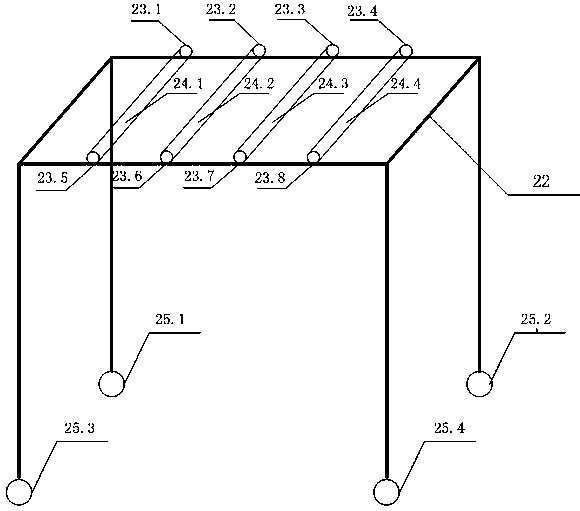

[0011] A fire hose drying device with direct combustion solution dehumidification and heat recovery according to the present invention will be further described below in conjunction with the illustrations.

[0012] Such as figure 1 , figure 2 , image 3 As shown, a direct-fired solution dehumidification and heat recovery fire hose drying device, including: return air outlet 1, absorber 2, fan 3, air inlet 4, lithium bromide dilute solution collector 5, solution pump 6, generator 7. Lithium bromide concentrated solution nozzle 8, air pipe 9, solution pipe 10, heat recovery device 11, electronic bypass ventilation valve 12, thermometer 13, flue gas pipe 14, drying chamber 15, personnel access door 16, fire hose inlet 17, Fire hose outlet 18, Y-shaped branch air duct 19, double-layer louver air outlet 20, fire hose 21, workbench 22, bearing 23, steel pipe 24, and wheels 25. The air return port 1 is connected to the air pipe 9.1, the air pipe 9.1 is connected to the absorber 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com