Liquid ammonia equipment monitoring system used for safety production accident potential safety hazard monitoring

A technology for hidden dangers of accidents and safe production, which is applied in signal transmission systems, closed-circuit television systems, televisions, etc., to achieve the effect of simple operation and true and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

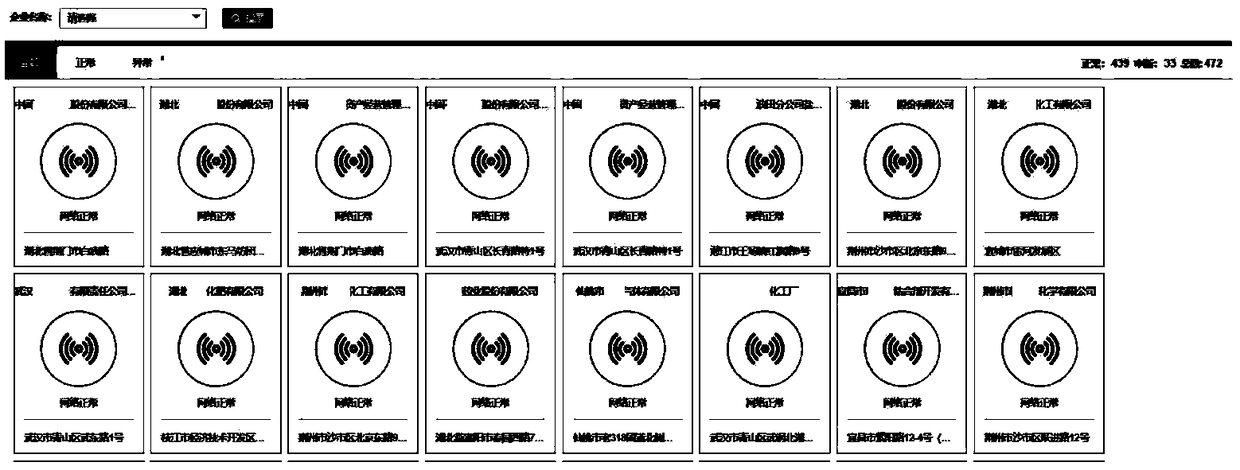

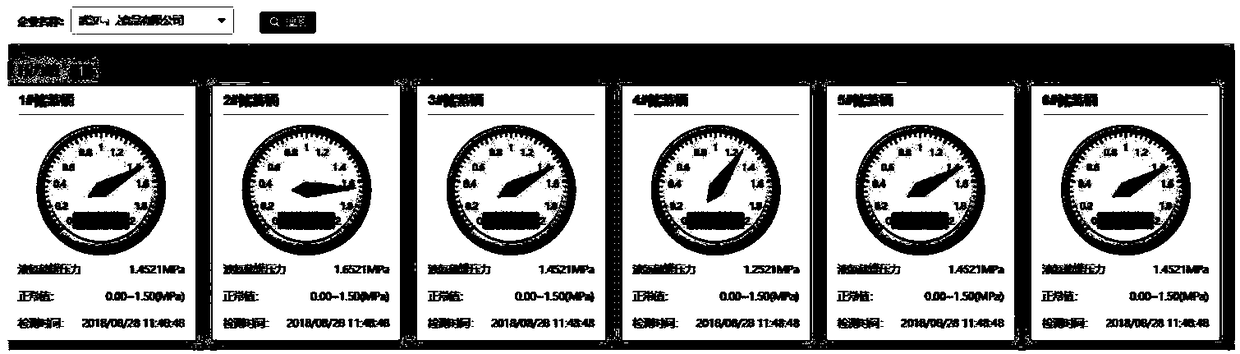

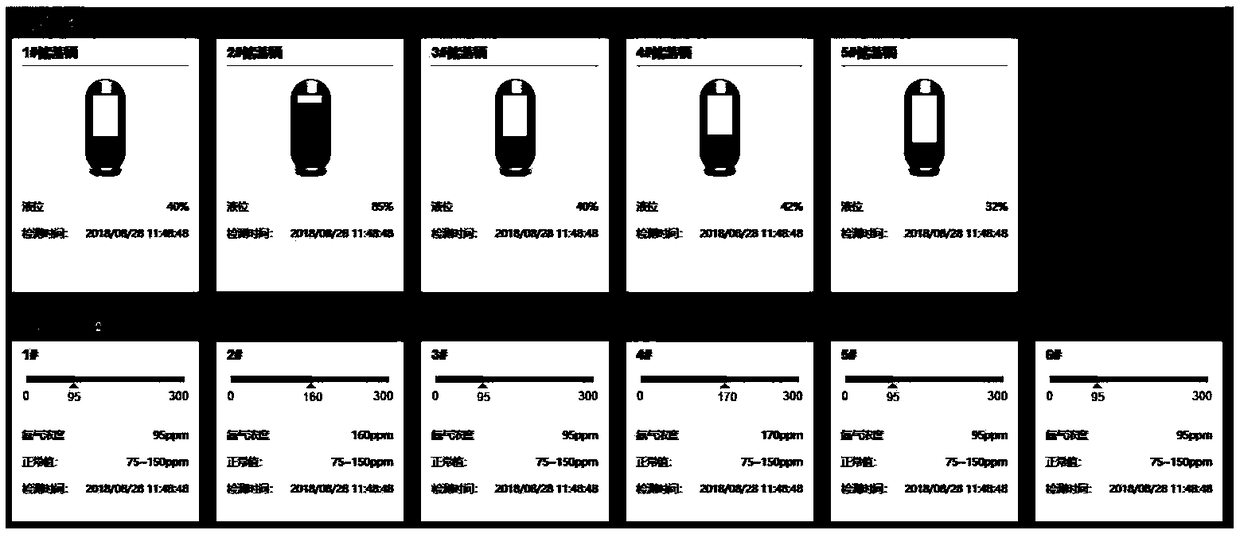

[0039] refer to figure 1 , which is a schematic diagram of an embodiment of the liquid ammonia equipment monitoring system for monitoring hidden dangers of production safety accidents according to the present invention. Sensor groups and video monitoring equipment are arranged in each company, and each liquid ammonia storage tank corresponds to a group of sensor groups , each group of sensors includes a pressure sensor, a concentration sensor and a liquid level sensor to respectively detect the pressure inside the barrel of the corresponding liquid ammonia storage barrel, the concentration of ammonia gas at the storage location, and the height of the liquid in the barrel. The video monitoring equipment is installed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com