Method for measuring orientation deviation angle of oriented silicon steel through X-ray diffraction

An oriented silicon steel, off-angle technology, used in material analysis using radiation diffraction, measuring devices, material analysis using wave/particle radiation, etc. Low, simple sample preparation, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

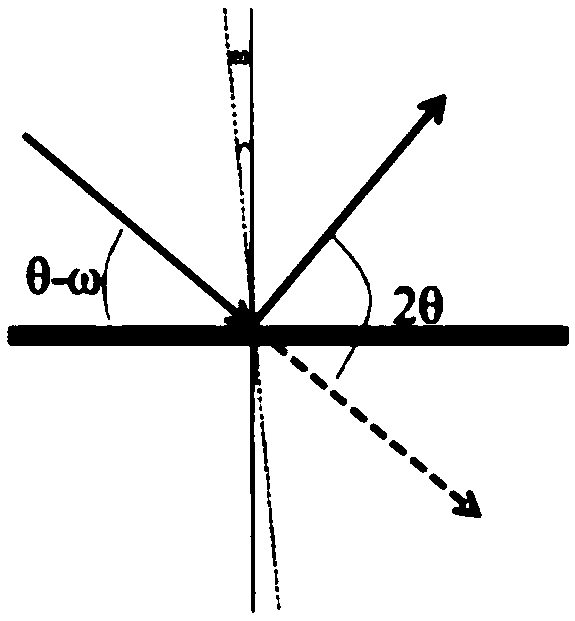

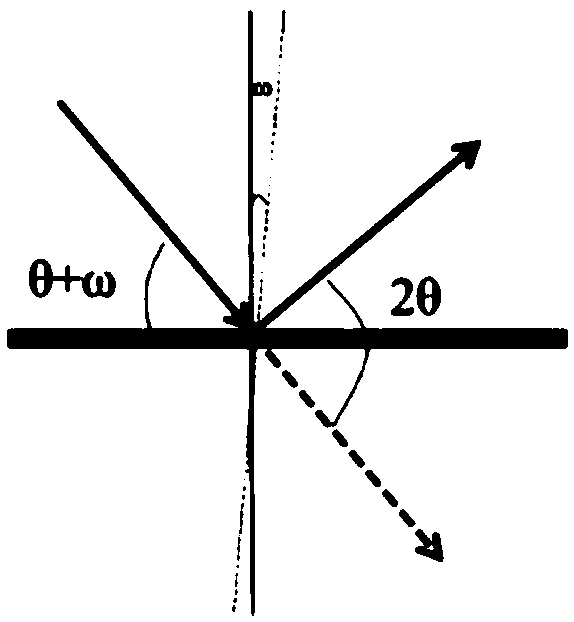

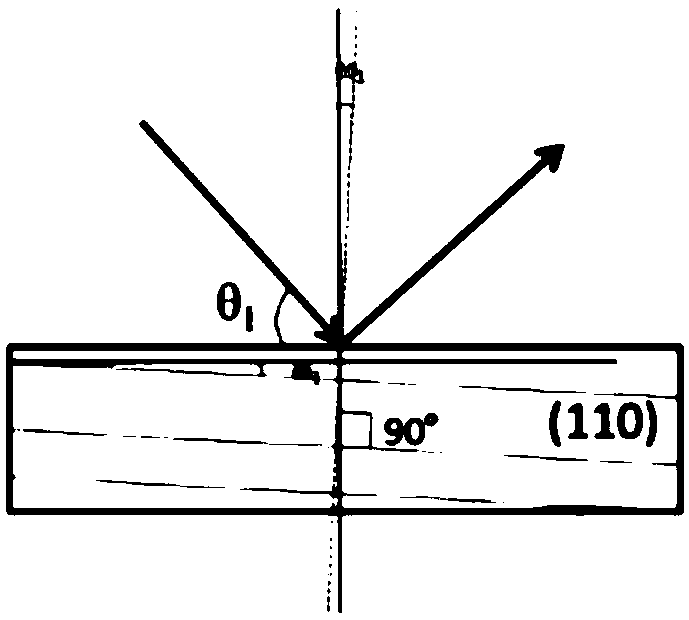

[0038] This embodiment provides a method for measuring the orientation deviation angle of grain-oriented silicon steel by X-ray diffraction, which includes the following steps:

[0039] S1, after placing the oriented silicon steel at the center of the sample stage, set the light pipe angle to θ 0 -α, detector at θ 0 +α-β to θ 0 Scan within the angle range of +α+β; set the light pipe angle to θ 0 -α+Δθ 1 , the detector at θ 0 +α+Δθ 1 -β to θ 0 +α+Δθ 1 Scan within the angle range of +β; and so on, at intervals of angle Δθ 1 Gradually increase the light pipe angle and scan; when a significant diffraction peak appears in the spectral line obtained by the detector, continue to 1 Gradually increase the light pipe angle to scan until the intensity of the diffraction peak shows a downward trend, that is, stop scanning and obtain the light pipe angle θ with the highest diffraction intensity m1 ;

[0040] S2, the light pipe angle θ with the highest diffraction intensity obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com