Blank initial residual stress high-precision reverse solving method based on a deformation test

A technology for residual stress and deformation testing, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of poor practicability and large errors, and achieve easy on-site implementation, simple methods, and high measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

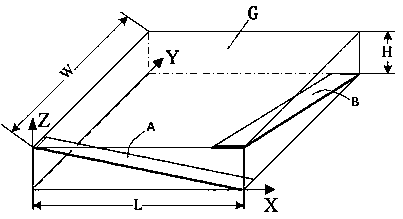

[0034] Embodiment: The blank G of the workpiece material is a 7075-T7451 aluminum alloy pre-stretched plate, its modulus of elasticity is E=70.5Gpa, and Poisson's ratio is ν=0.33. The size of blank G is length L=410mm, width W=410mm, height H=60mm, where: X direction is the rolling direction, Y direction is the transverse direction, Z direction is the thickness direction, such as figure 1 shown.

[0035] According to the steps of the residual stress test method, the implementation process of the stress test is determined as follows:

[0036] Step 1: Determine the part to be tested:

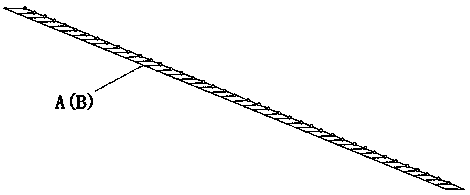

[0037] From the blank G, a thin plate with a width of 20mm and a thickness of 1.5mm is processed along the rolling direction X and the transverse direction Y respectively as the part to be tested, wherein: the part to be tested along the rolling direction X is named the first part to be tested A, the part to be tested along the transverse direction Y is named as the second part to be tested B, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com