Waste power battery discharging device

A technology for used batteries and discharge devices, applied in battery circuit devices, circuit devices, secondary batteries, etc., to achieve the effects of unaffected work efficiency, increased processing costs, and increased transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

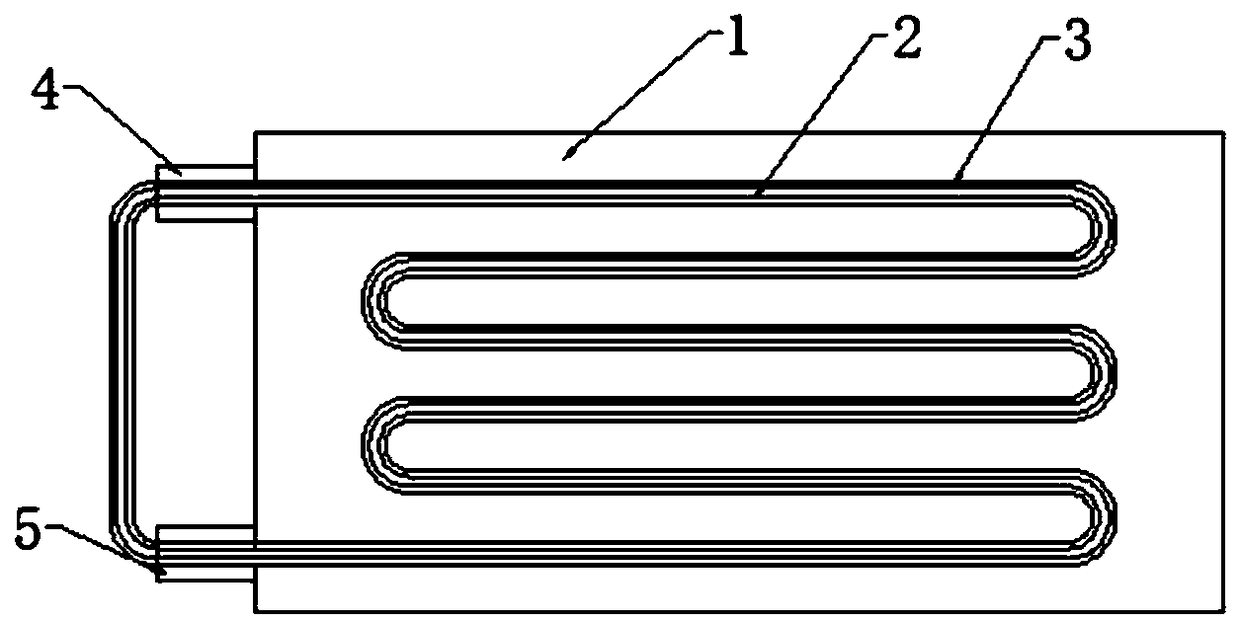

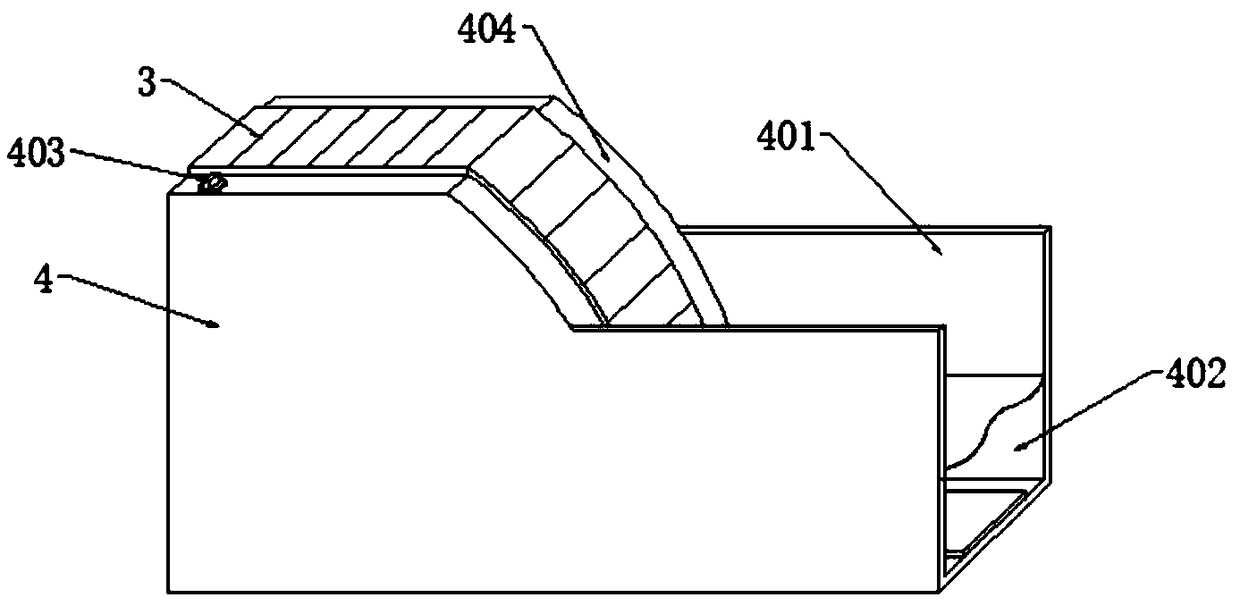

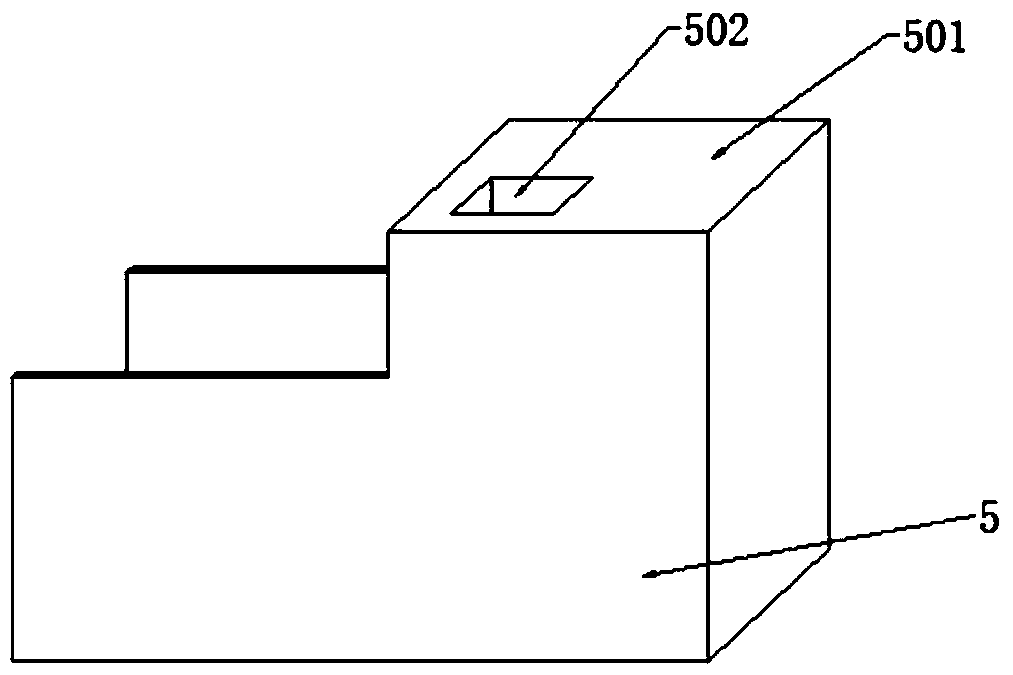

[0027] Such as Figure 1-5 As shown, a waste power lithium battery discharge device includes a discharge battery 1, a discharge tank 2 and a waste battery transmission rail 3, the discharge battery 1 is provided with a discharge tank 2, and the discharge tank 2 is coiled in the discharge battery 1 , the inside of the discharge tank 2 is provided with a waste battery transmission rail 3, the waste battery transmission rail 3 is a closed loop rail, the battery discharge 1 side is provided with a waste battery recovery platform 4, and the waste battery recovery platform 4 side is A waste battery treatment platform 5 is provided, one side of the waste battery recovery platform 4 is closely connected with the discharge tank 2, and the waste battery conveying rail 3 is laid on the waste battery recovery platform 4 along the way, and one side of the waste battery treatment platform 5 is provided with A waste battery drop-in box 501 , the bottom side of the used battery drop-in box 50...

Embodiment 2

[0029] Such as Figure 1-5 As shown, a waste power lithium battery discharge device includes a discharge battery 1, a discharge tank 2 and a waste battery transmission rail 3, the discharge battery 1 is provided with a discharge tank 2, and the discharge tank 2 is coiled in the discharge battery 1 , the inside of the discharge tank 2 is provided with a waste battery transmission rail 3, the waste battery transmission rail 3 is a closed loop rail, the battery discharge 1 side is provided with a waste battery recovery platform 4, and the waste battery recovery platform 4 side is A waste battery treatment platform 5 is provided, one side of the waste battery recovery platform 4 is closely connected with the discharge tank 2, and the waste battery conveying rail 3 is laid on the waste battery recovery platform 4 along the way, and one side of the waste battery treatment platform 5 is provided with A waste battery drop-in box 501 , the bottom side of the used battery drop-in box 50...

Embodiment 3

[0032] Such as Figure 1-5 As shown, a waste power lithium battery discharge device includes a discharge battery 1, a discharge tank 2 and a waste battery transmission rail 3, the discharge battery 1 is provided with a discharge tank 2, and the discharge tank 2 is coiled in the discharge battery 1 , the inside of the discharge tank 2 is provided with a waste battery transmission rail 3, the waste battery transmission rail 3 is a closed loop rail, the battery discharge 1 side is provided with a waste battery recovery platform 4, and the waste battery recovery platform 4 side is A waste battery treatment platform 5 is provided, one side of the waste battery recovery platform 4 is closely connected with the discharge tank 2, and the waste battery conveying rail 3 is laid on the waste battery recovery platform 4 along the way, and one side of the waste battery treatment platform 5 is provided with A waste battery drop-in box 501 , the bottom side of the used battery drop-in box 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com