Waste gas treatment device and process of water based paint

A technology of waste gas treatment device and water-based paint, applied in gas treatment, combination device, membrane technology and other directions, can solve the problems of inability to paint waste gas odorous gas substances, short construction period, inhalation into the body, etc., to avoid frequent cleaning and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

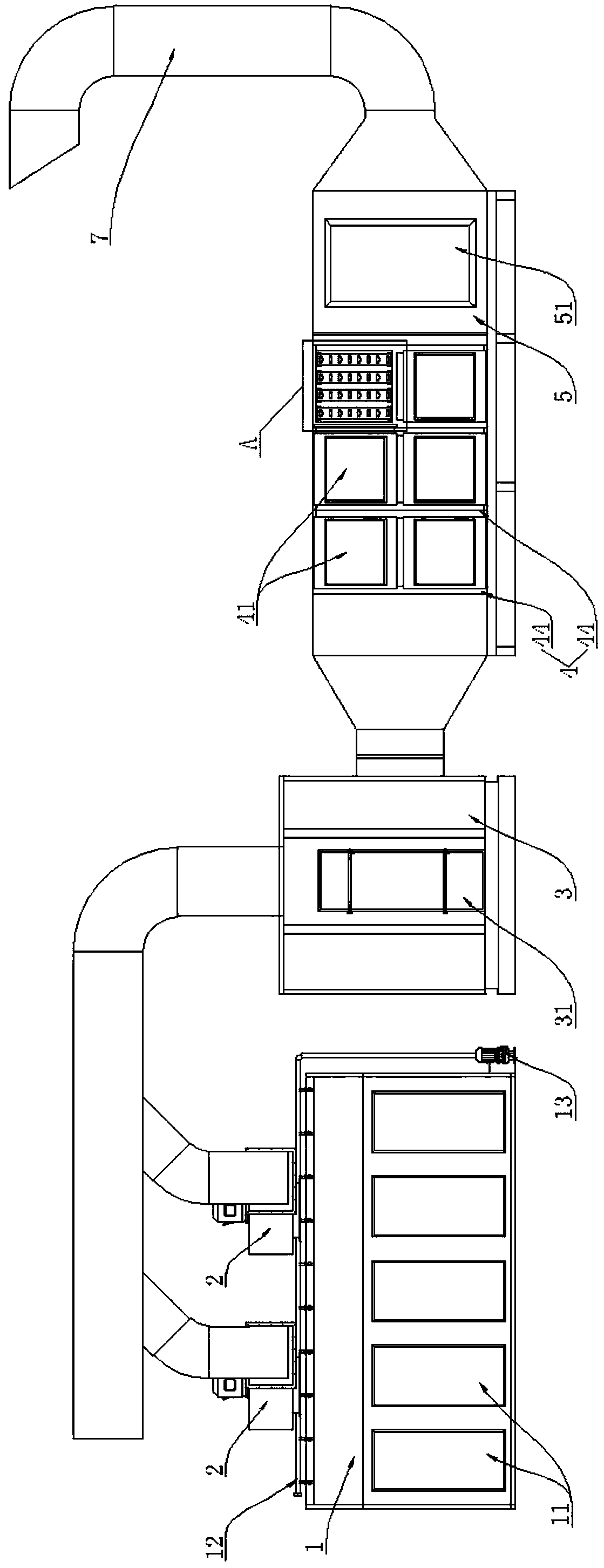

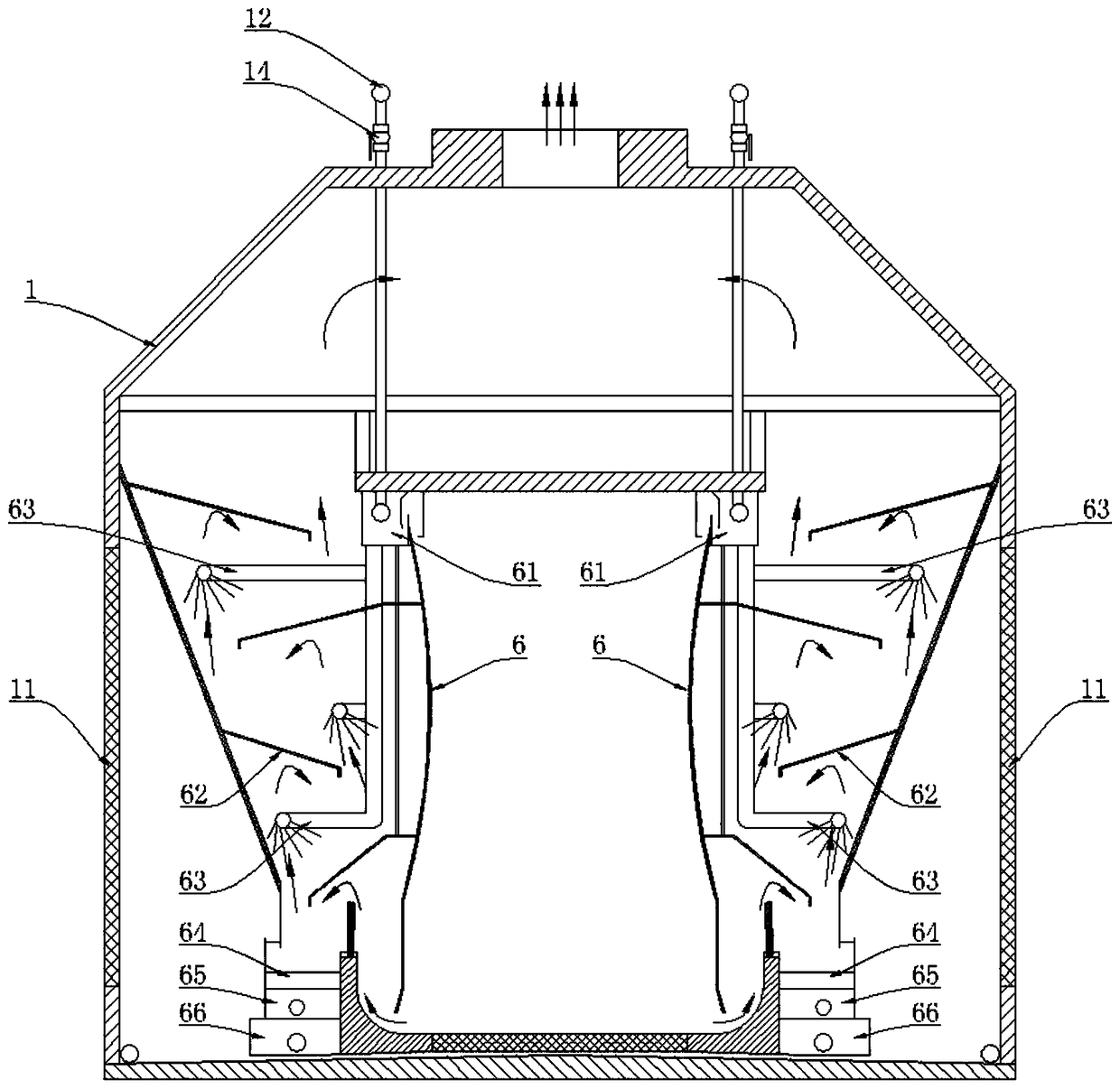

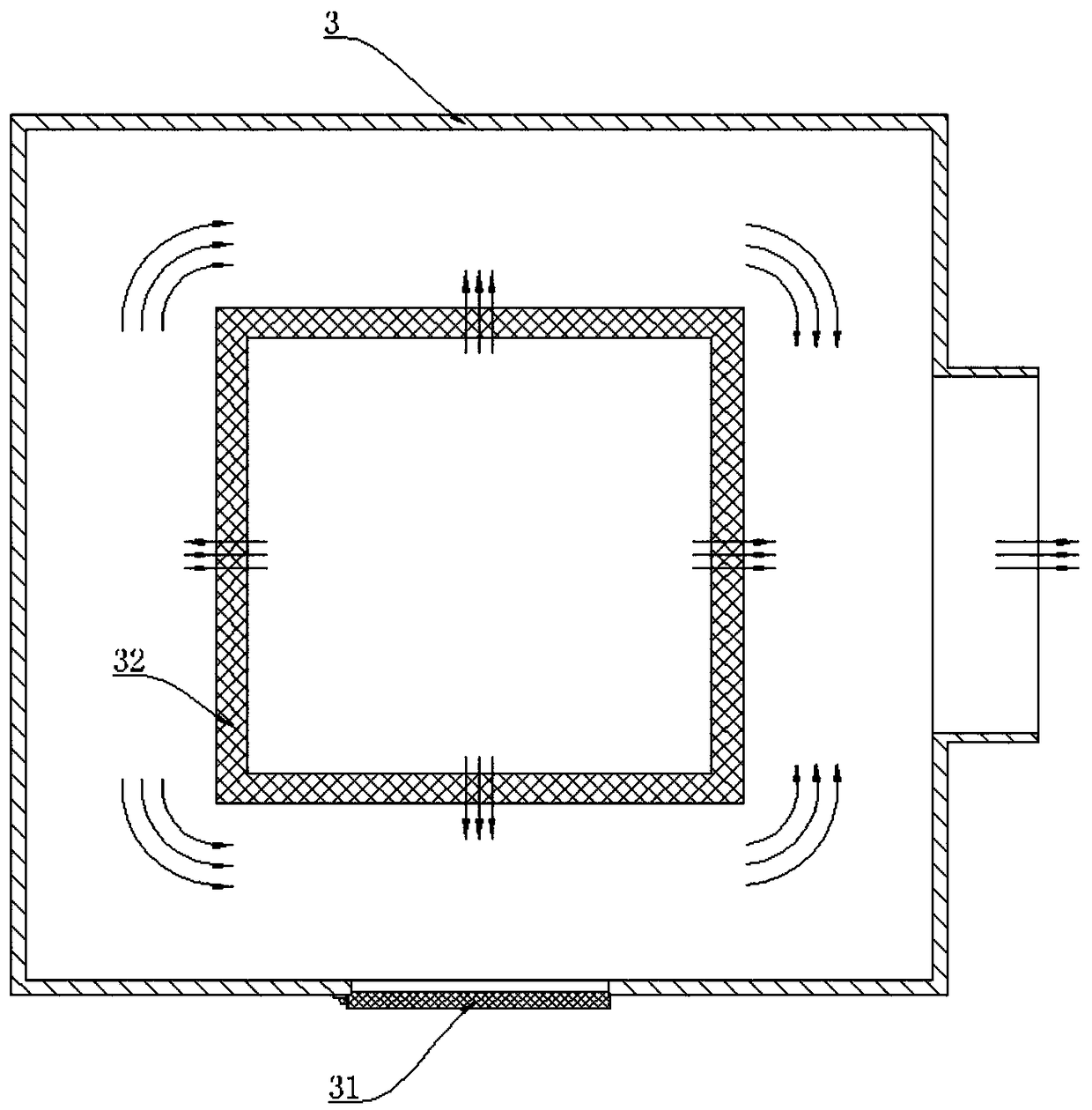

[0038] see Figure 1 to Figure 7 As shown, a water-based paint exhaust gas treatment device includes a water spin paint mist treatment cabinet 1, a filter purification chamber 3, a photocatalytic purification chamber 4, an activated carbon purification chamber 5, an exhaust chimney 7, and a water spin paint mist treatment cabinet connected sequentially through pipelines. A fan 2 for driving the flow of exhaust gas is arranged between the processing cabinet 1 and the filtration purification chamber 3;

[0039] The water cyclone paint mist treatment cabinet 1 is provided with a water curtain and a spray device 63 for absorbing paint mist particles, and the waste gas treated by the water cyclone paint mist treatment cabinet 1 is filtered twice in the filtration purification room 3, and further adsorbed in the waste gas. paint mist particles, and remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com