Three-stage piston pushing centrifuge drum device

A three-stage piston and centrifuge technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problem of inability to separate low-concentration suspended materials and fine powder materials, narrow material adaptation range, and short service life of the screen. and other problems, to achieve the effect of improving the dehydration effect, increasing the scope of application, and reducing the amount of running material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

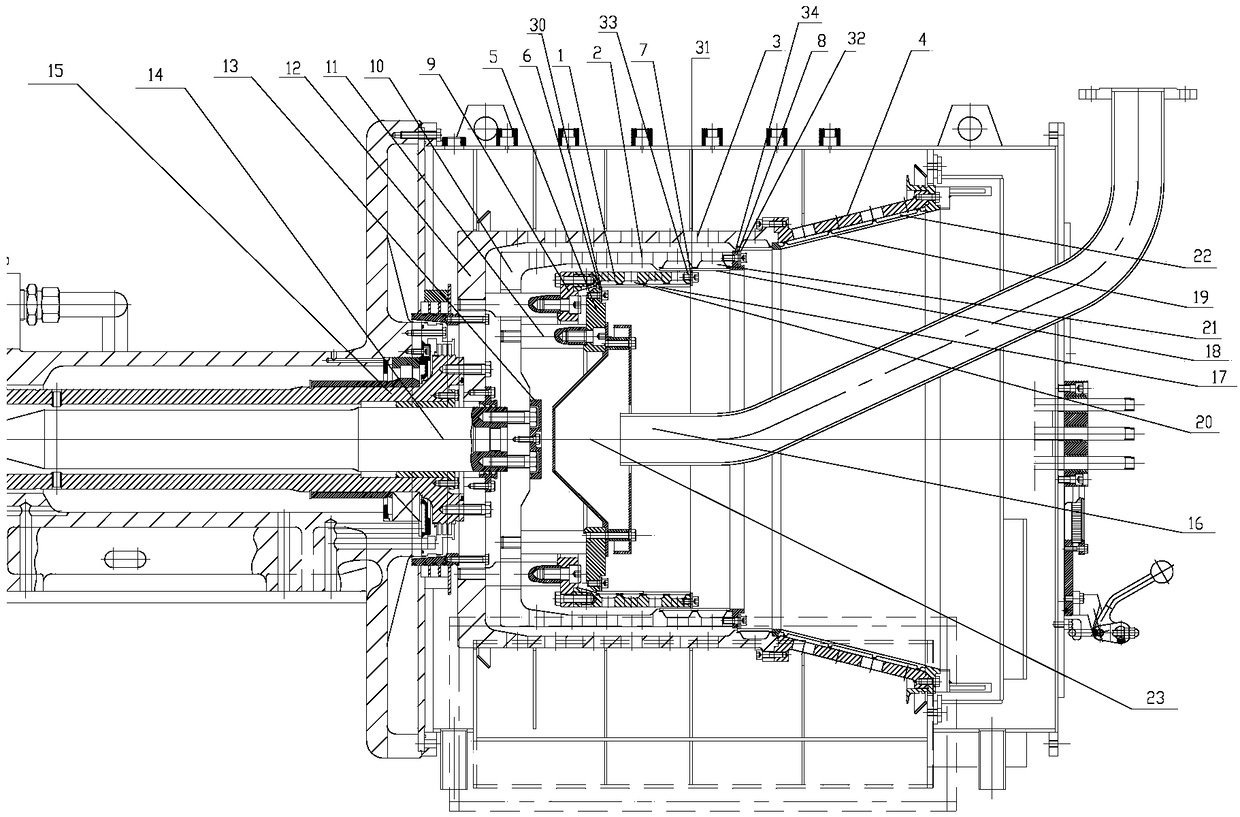

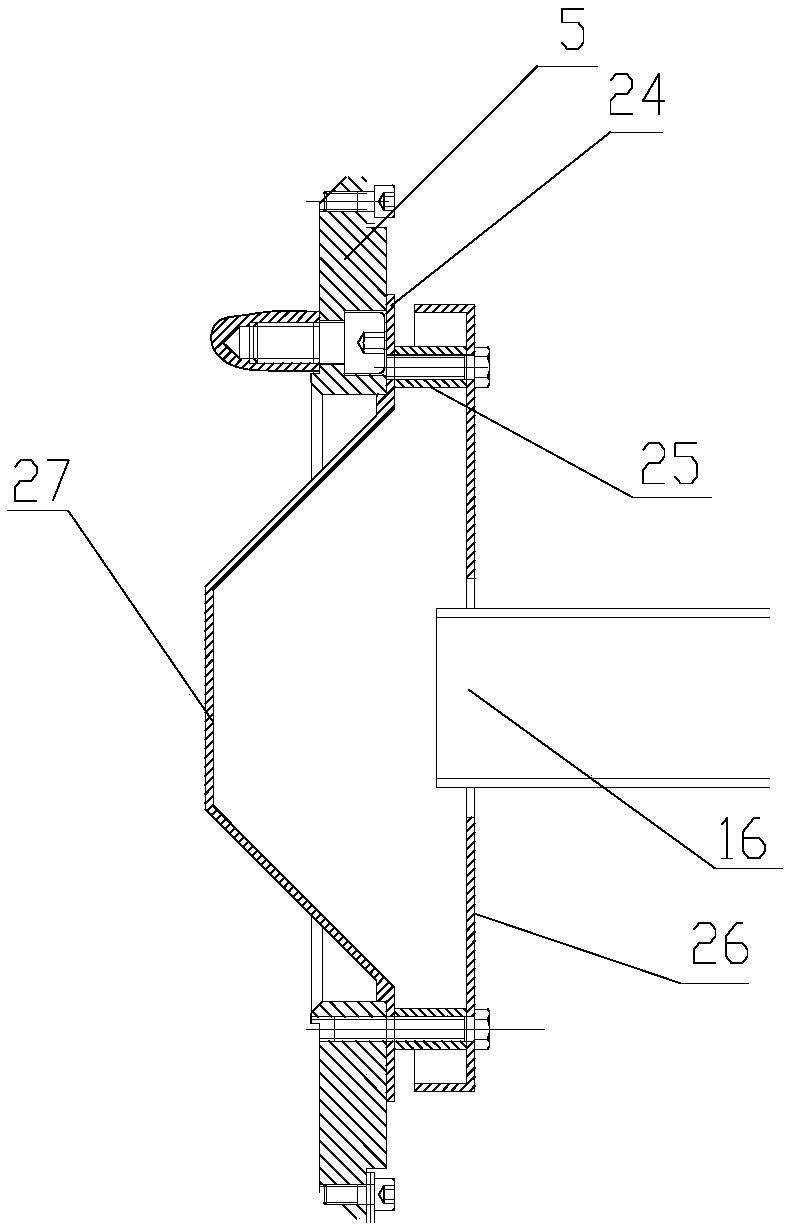

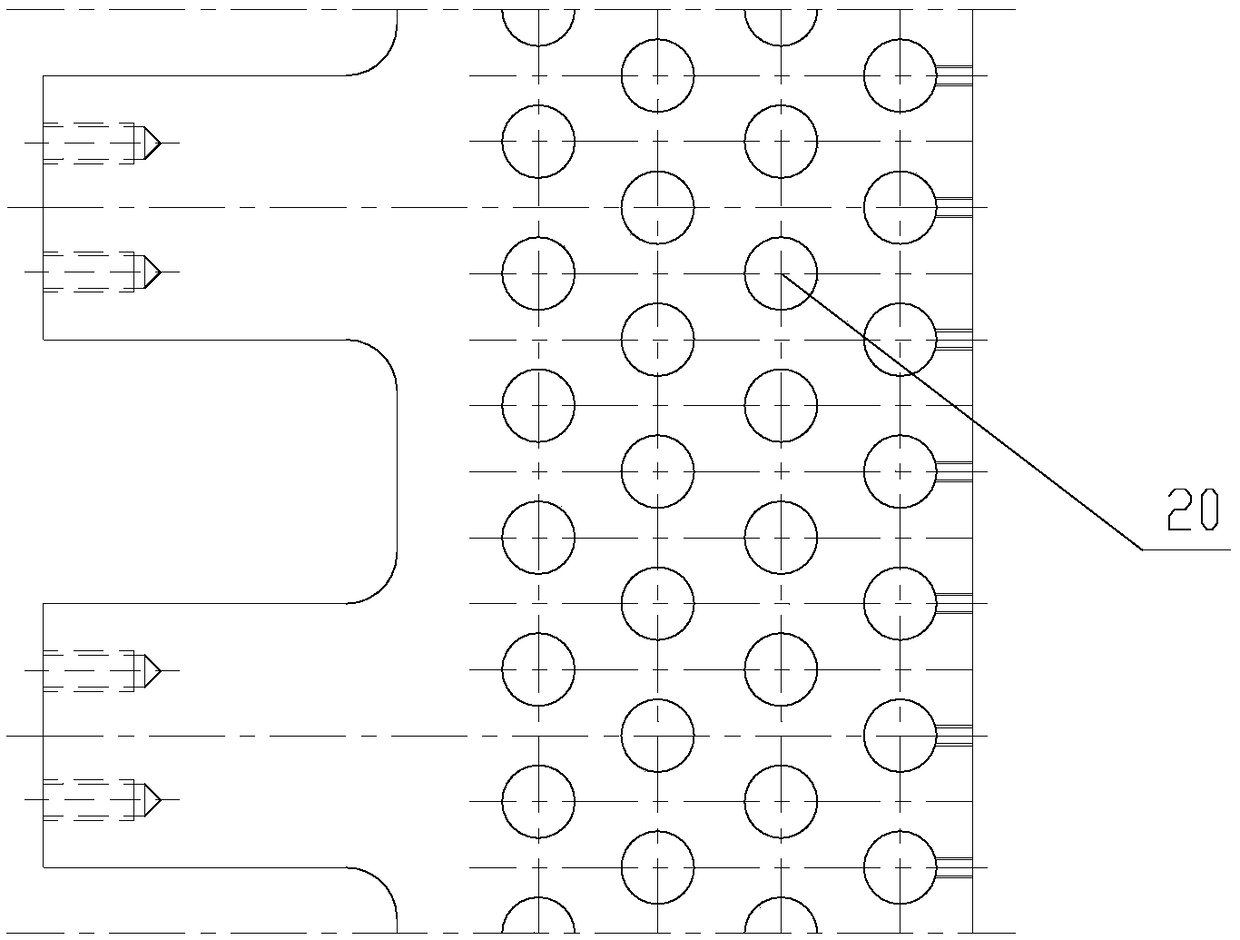

[0026] like figure 1 As shown, a three-stage piston pusher centrifuge drum device according to the present invention includes a first-stage drum 1, a second-stage drum 2 and a third-stage drum, and the third-stage drum adopts Cylindrical cone structure, that is, includes a circular segment 3 and a conical segment 4 . The conical structure makes the centrifugal force of the drum stronger, and the moisture content of the material at the discharge port is lower after being dried; the front section of the third-stage drum is round and unchanged, and the rear section is changed to a cone shape. This structure not only makes the material under the centrifugal force Under the action, it automatically goes to the back section, reducing the resistance, and the material becomes thinner as it goes to the back section, thereby reducing the moisture content of the material. The circular segment 3 is fixedly connected with the third-stage drum bottom 12, and the third-stage drum bottom 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com