Functional plastic banburying method and banbury mixer

A functional and internal mixer technology, applied in the field of internal mixer and functional plastic internal mixing, can solve the problems of low smelting efficiency, increased energy consumption, reduced smelting efficiency, etc. The effect of heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

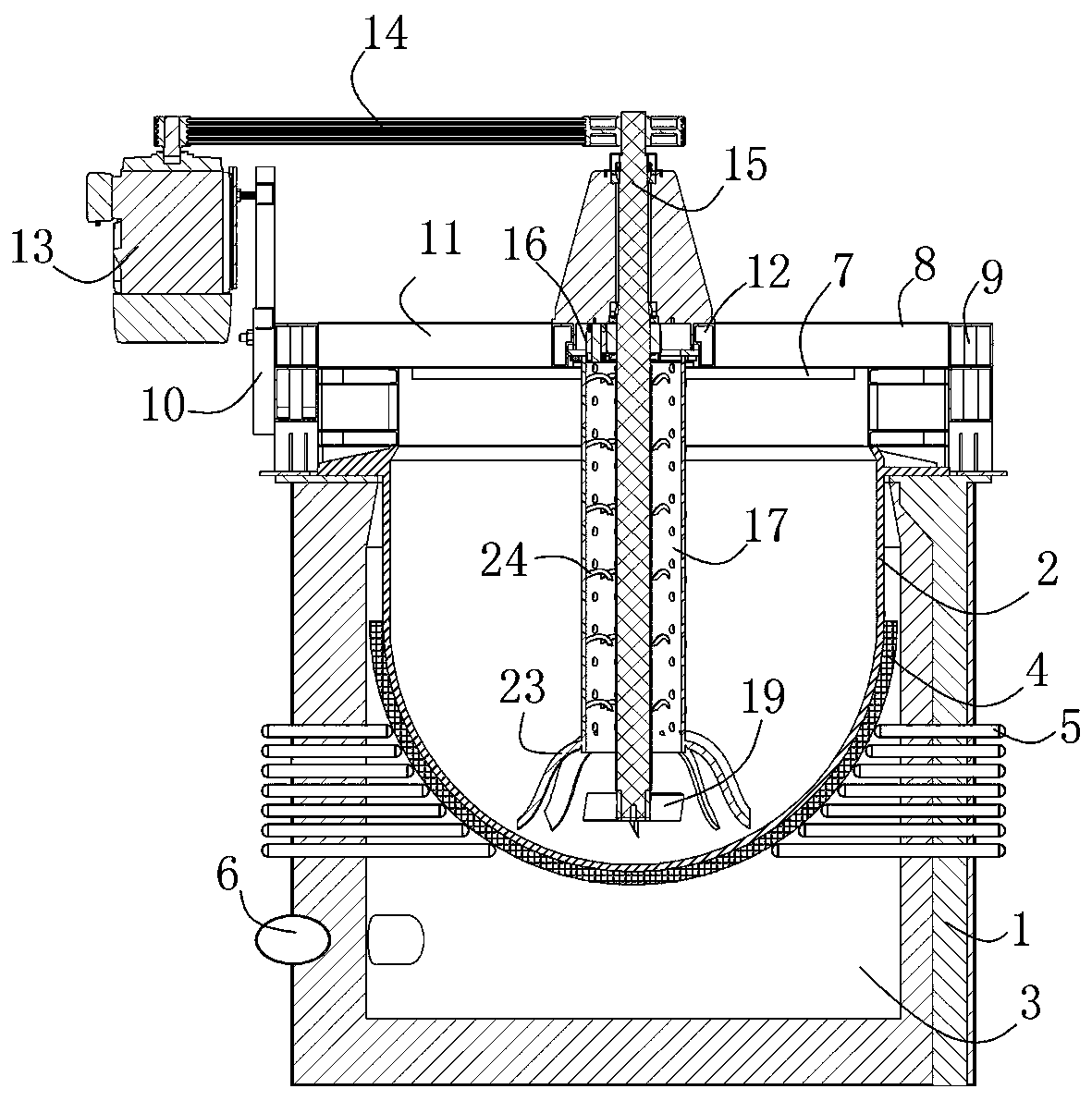

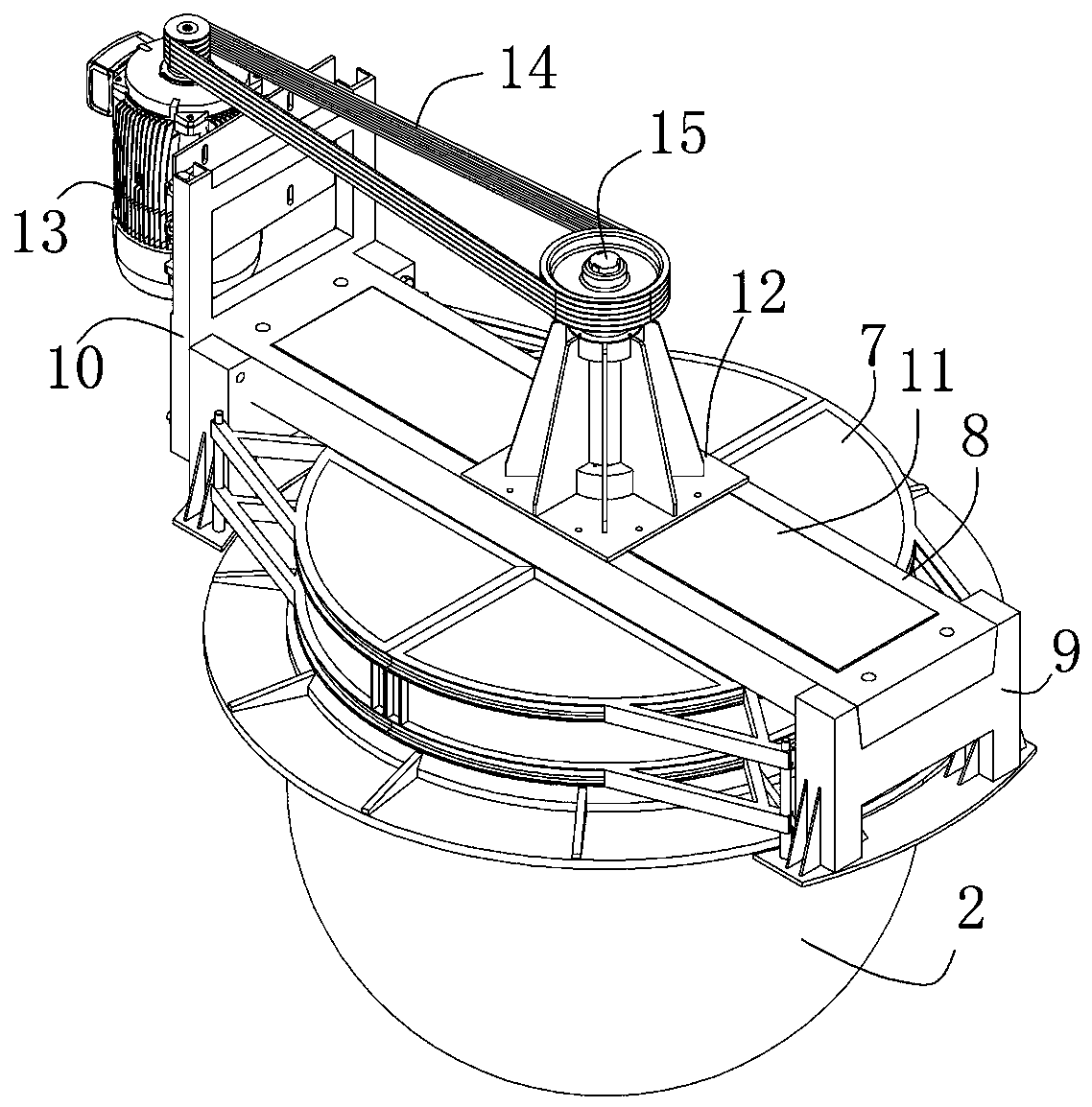

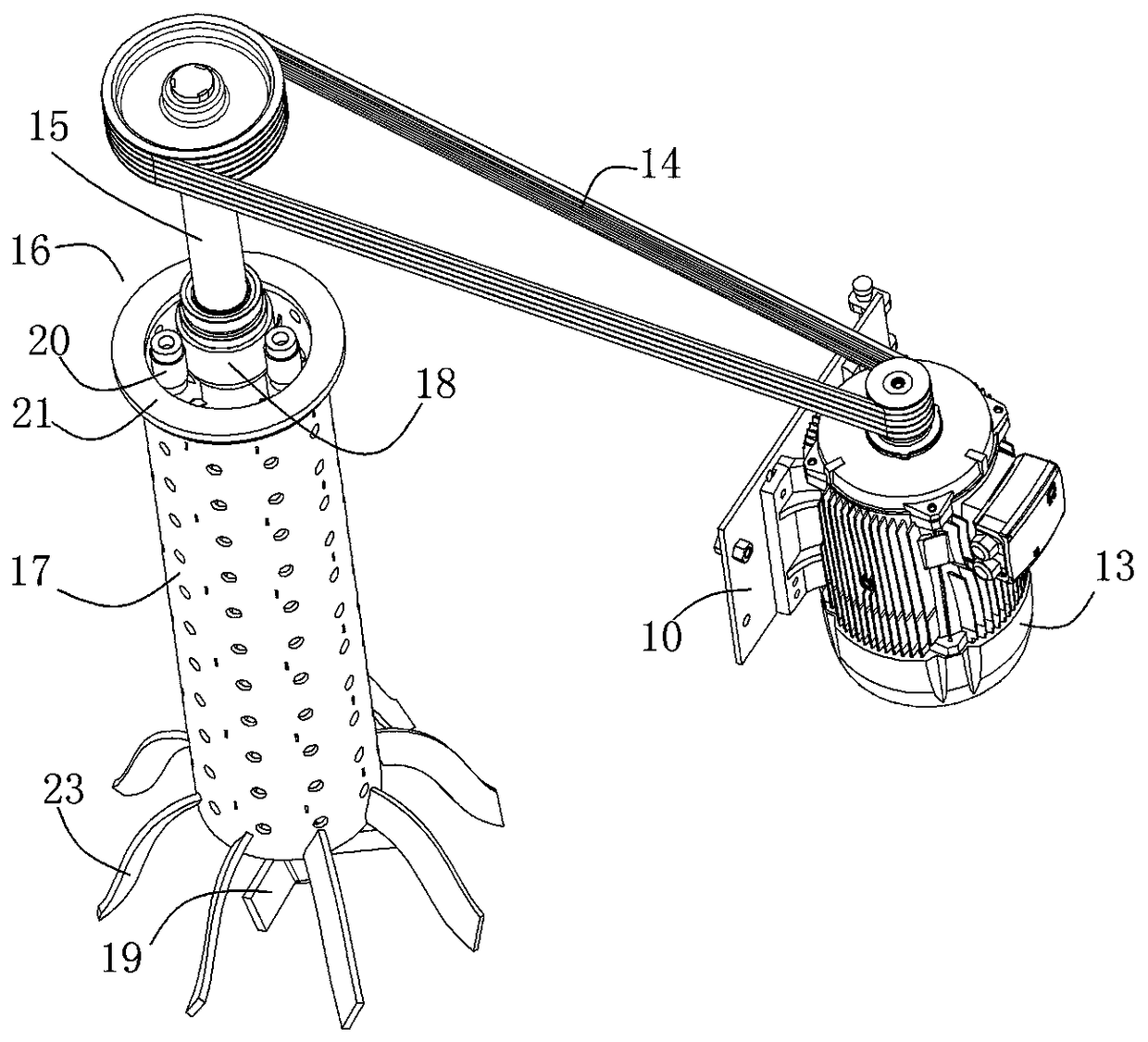

[0027] refer to figure 1 , shows the structure diagram of the internal mixer specially used for functional plastic internal mixing in the present invention, the main structure of which remains the structure of the existing internal mixer, and the improvement mainly lies in the innovation of the heating method and the stirring method. Below in conjunction with accompanying drawing, its main structure is described.

[0028] The internal mixer is mainly composed of an insulating shell 1, a pot body 2, a heating system and a stirring system.

[0029] The insulation shell 1 adopts a cylindrical structure, and an interlayer is arranged on the wall of the cylinder, and the interlayer is filled with insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com