High-performance waterproof sealing ring and manufacturing process thereof

A waterproof sealing and manufacturing process technology, applied in other household appliances, household components, household appliances, etc., can solve the problems of high secondary injection pressure, poor waterproof performance of sealing rings, poor sealing performance of PIN needle assembly, etc. Infiltration, excellent waterproof performance, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

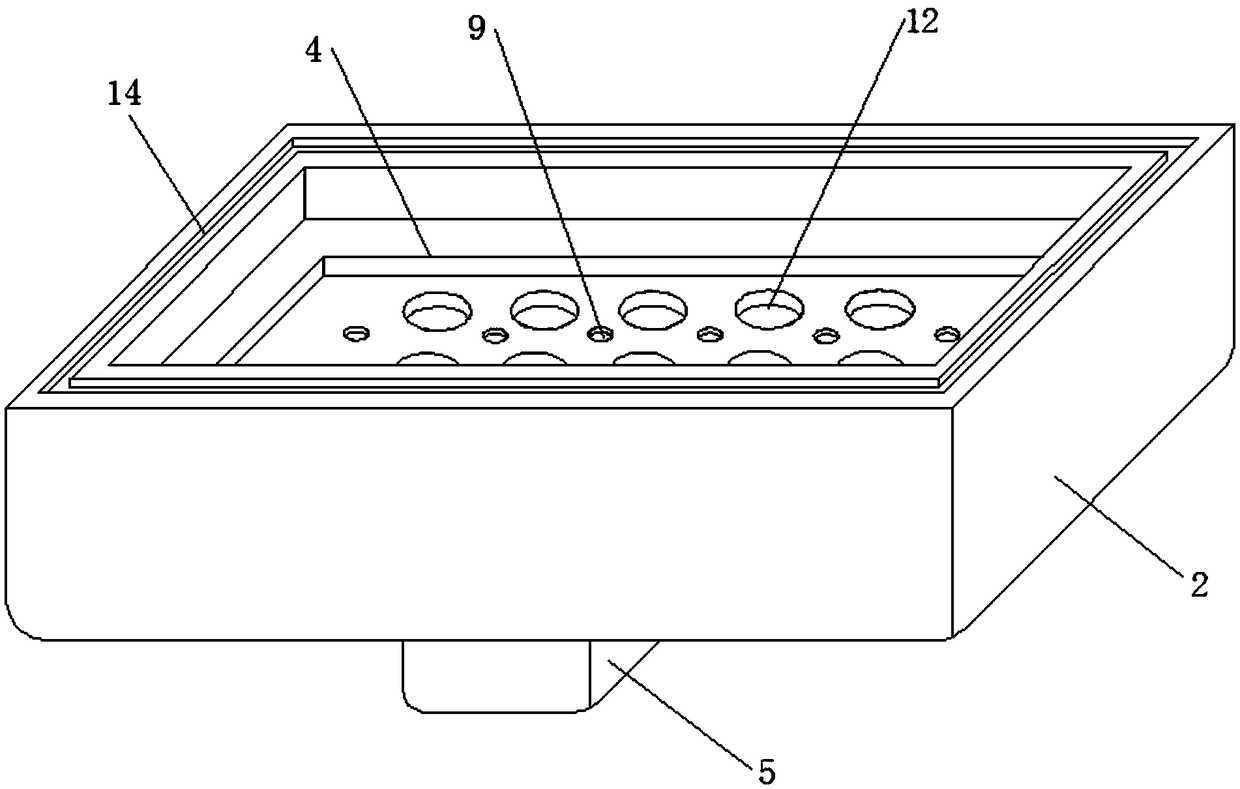

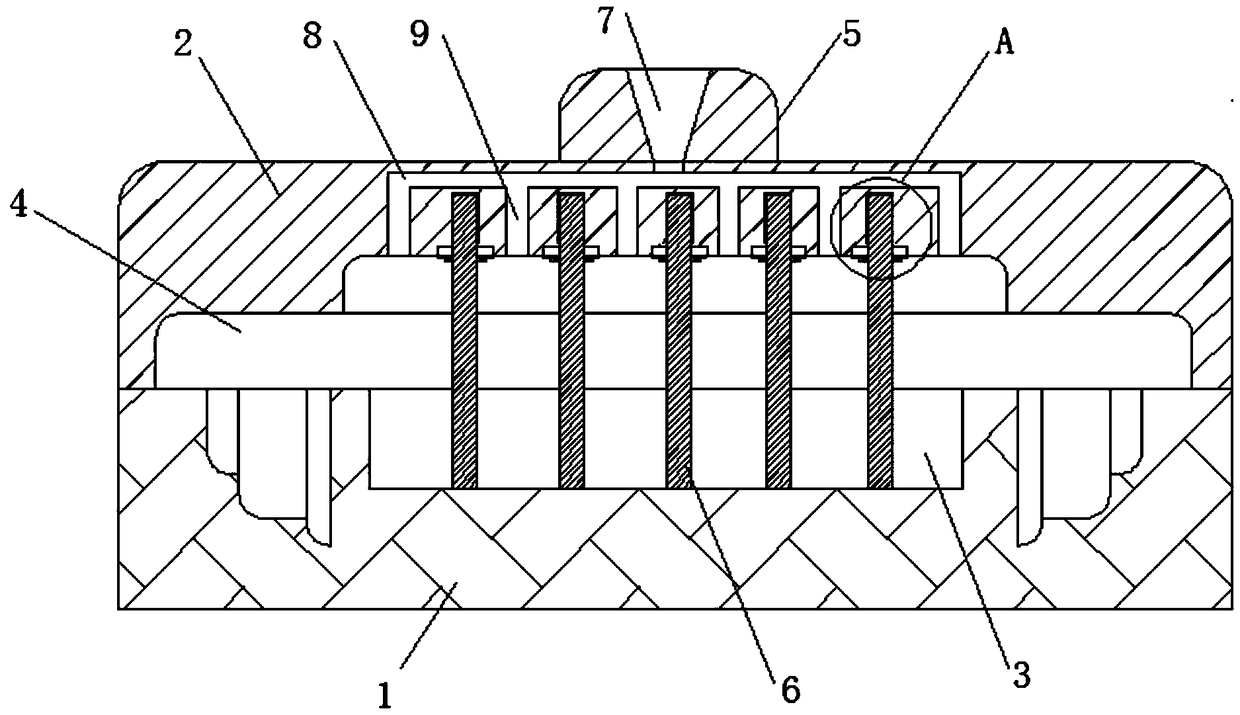

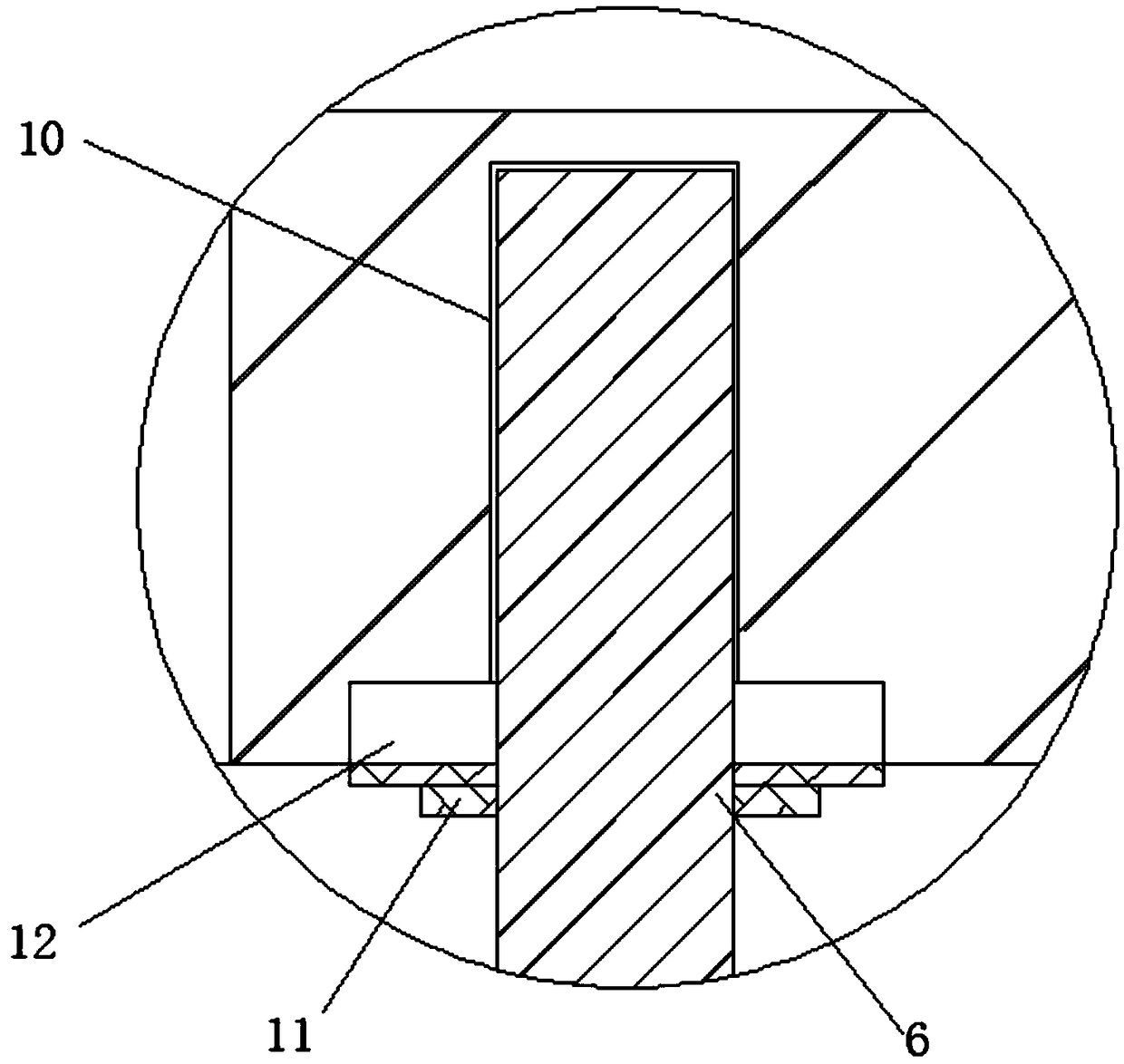

[0049] see Figure 8 , a high-performance waterproof sealing ring, including a gyro-type sealing ring 15 arranged on a PIN needle 6, and its manufacturing process includes:

[0050] The first step is preparation. The lower end of the PIN pin 6 is vertically fixed to the inner bottom of the mold, and the end of the PIN pin 6 away from the bottom of the mold is clamped with a connecting ring 11;

[0051] The second step is the first closed mold injection molding, injection molding from the top of the mold to the inside of the mold;

[0052] The third step is to open the mold for the first time and adjust the mold;

[0053] The fourth step is the second closed mold injection molding, and then injection molding from the top of the mold to the inside of the mold;

[0054] The fifth step is to open the mold for the second time and clean up the corners of excess sealing material.

[0055] The sealing ring 15 can be integrally synthesized on the injection molding block and the PIN ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com