A bean chip press machine

A technology for pressing machines and bean chips, which is applied to punching machines, presses, manufacturing tools, etc., and can solve problems such as hard and poor taste of bean chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

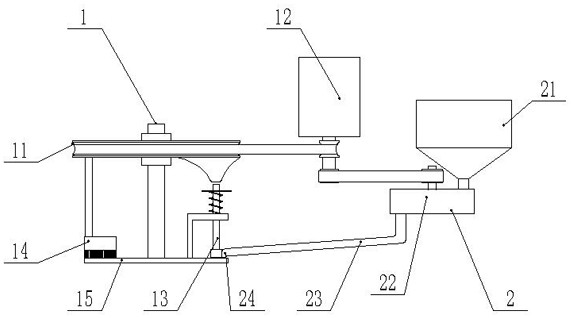

[0029] Such as Figure 1 to Figure 5 Shown: a bean flakes pressing machine, including: a hammer pressing part 1 and a feeding part 2; one side of the hammer pressing part 1 is provided with a feeding part 2 for adding beans,

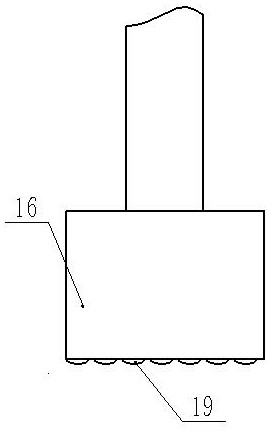

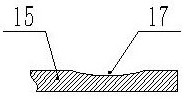

[0030] The hammer pressing part 1 includes: a hammer pressing cam 11, a motor 12, a pressing hammer 13, a feeding brush 14 and a pressing plate 15; the hammer pressing cam 11 is arranged horizontally, and the hammer pressing cam 11 is connected to the output shaft of the motor 12 through a belt , the lower end surface of the hammer pressing cam 11 is provided with a protruding block and a feed brush 14, the lower end of the feeding brush 14 and the lower end of the protruding block have the same distance from the center of the hammer pressing cam 11, and the lower end of the protruding block is provided with Pressing plate 15, a support rod is fixed on the upper end surface of the pressing plate 15, and a through hole is arranged on the supporting rod. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com