A bottom slag smelting device for reducing coarse magnesium with a buffer structure

A buffer structure and smelting device technology, applied in the field of magnesium smelting, can solve the problems of incomplete collection, inability to ensure the penetration of magnesium gas, uneven and incomplete heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

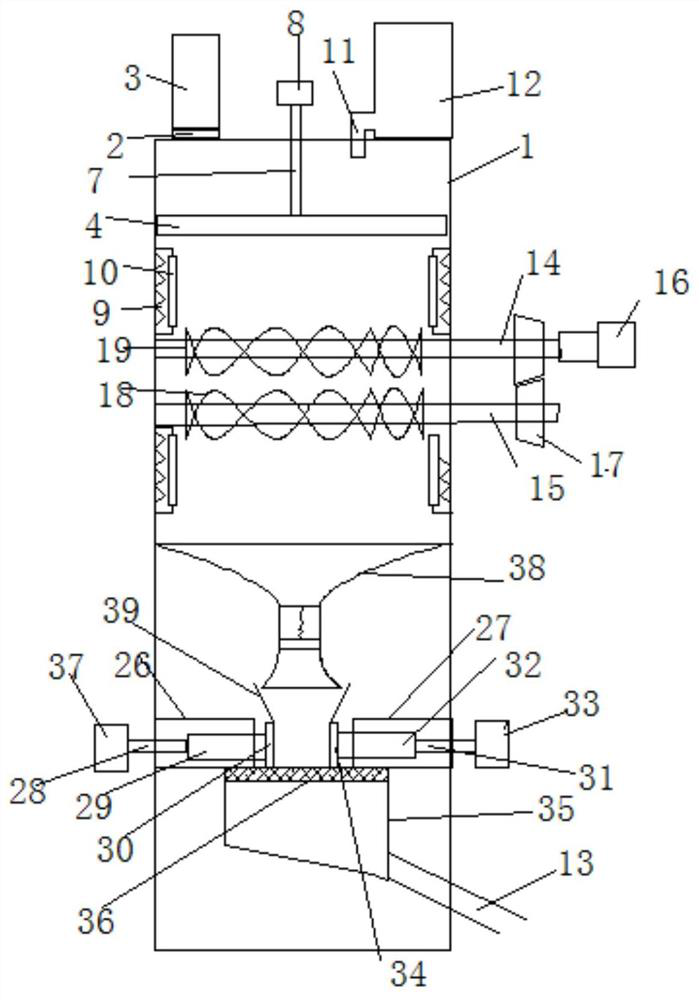

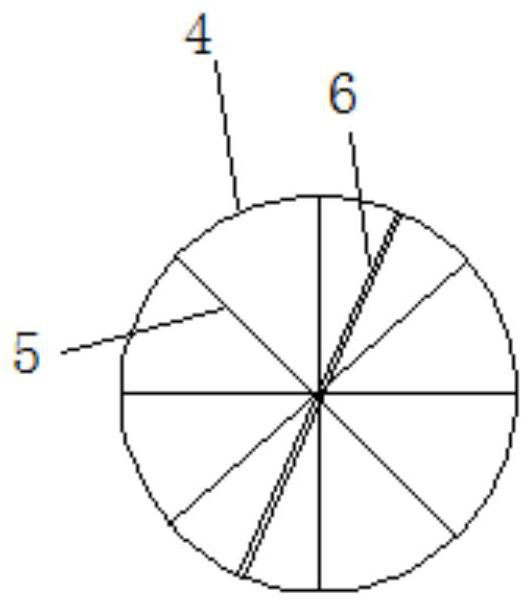

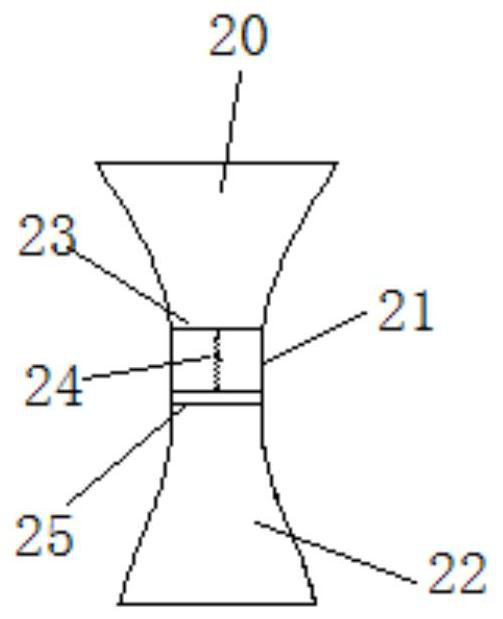

[0022] like figure 1 As shown, a reduced crude magnesium bottom slag smelting device with a buffer structure includes a cylindrical furnace 1, a feed inlet is opened at the top of the furnace 1, and a check valve 2 is arranged at the feed inlet. The feed inlet described above is also connected with a feed pipe 3, and a circular dispersing swivel 4 is arranged inside the furnace 1, and a plurality of steel wire retaining rods 5 are radially arranged inside the swivel 4, The middle position of the fixed rod 6 is fixed, the lower end of the rotating shaft 7 is fixedly connected to the center of the fixed rod 6, the upper end of the rotating shaft 7 passes through the top of the furnace 1, and the first motor 8 is installed above the furnace 1, and the upper end of the rotating shaft 7 is connected to the furnace. The output end of the first motor 8 is connected, a stirring device is provided under the swivel 4, and an electric heating wire 9 and a cooling fin 10 are arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com