Energy-saving and environment-friendly industrialized fabricated house structure

An industrialized assembly, energy saving and environmental protection technology, applied in the direction of building components, building structure, construction, etc., can solve the problems of noise pollution, unfavorable transportation and installation, dust pollution, etc., to block the cold bridge effect, convenient and fast installation, and installation The effect of energy saving and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

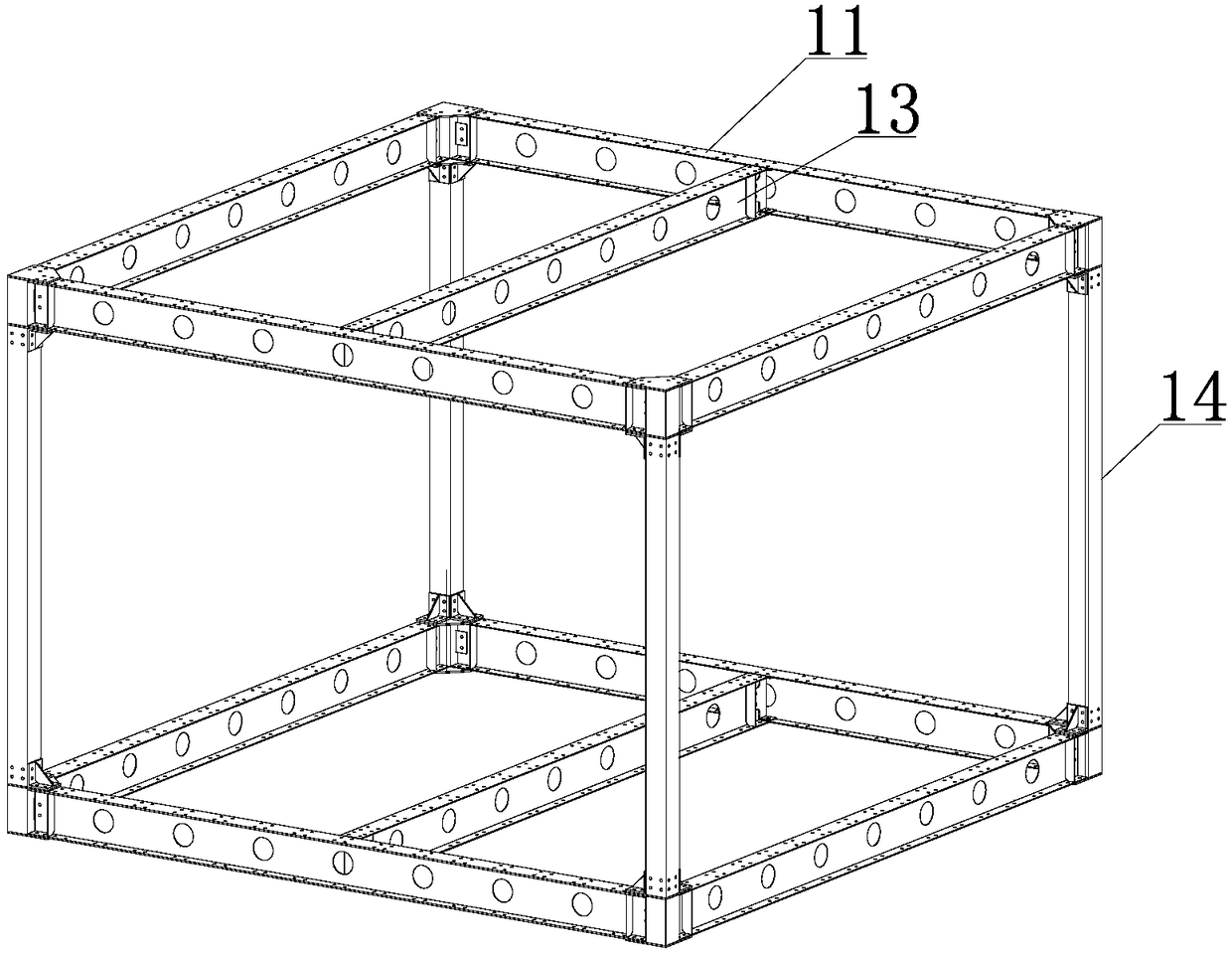

[0032] The invention will be further described in detail below in conjunction with the drawings.

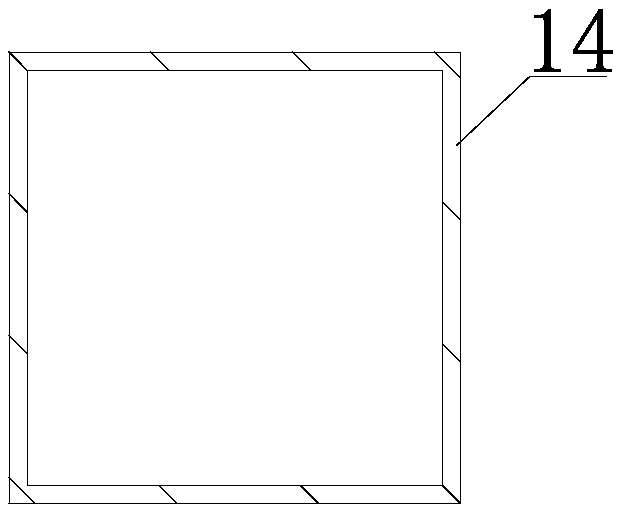

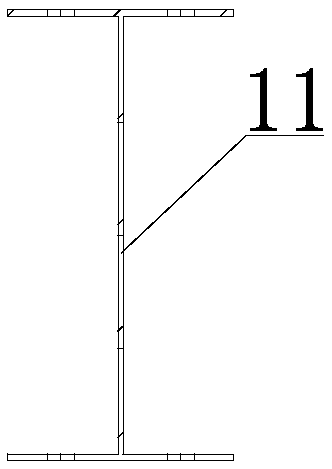

[0033] Such as Figure 1-18 As shown, an energy-saving and environmentally-friendly industrialized prefabricated house structure includes a frame body module, a node module arranged at the intersection of the frame body module, and a wall panel module provided on each surface on the frame body module , The floor module is arranged on the level of the frame body module, the roof module is arranged on the top of the frame body module, and the stair module is arranged on the floor module. The frame body module includes a plurality of frame beams 11 spliced into a square body and frame columns 12 that support the upper and lower frame beams 11 on the frame beams 11; the two frame beams 11 are provided with a cross connecting the two frame beams 11 respectively. The frame beam 13; the point module includes a first node 21 connecting the frame beam 11 and the frame column 12 respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com