Offshore platform automation workover machine upper tube manipulator

A technology for offshore platforms and manipulators, applied to manipulators, drill pipes, casings, etc., can solve problems such as danger, low efficiency, and manipulators that cannot meet needs, and achieve the effects of good safety, simple and reliable structure, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

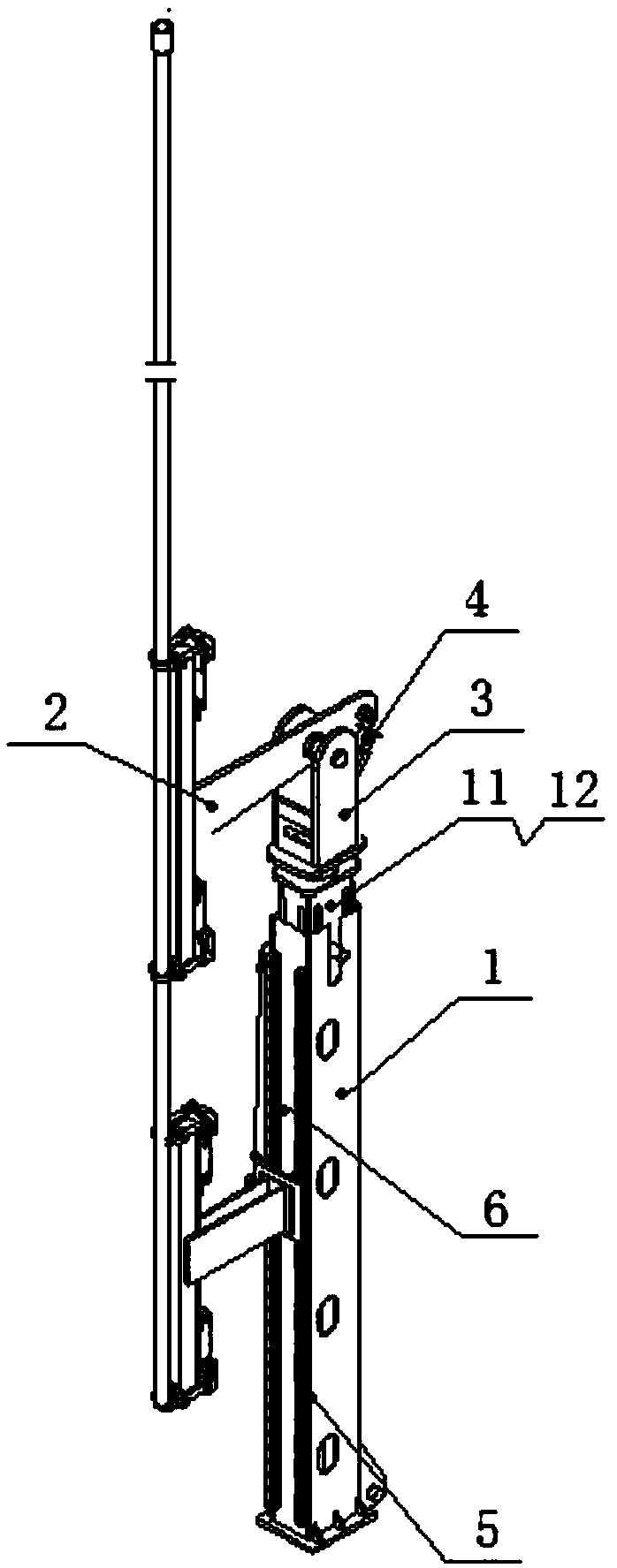

[0017] figure 1 Shown is the structural representation of the present invention.

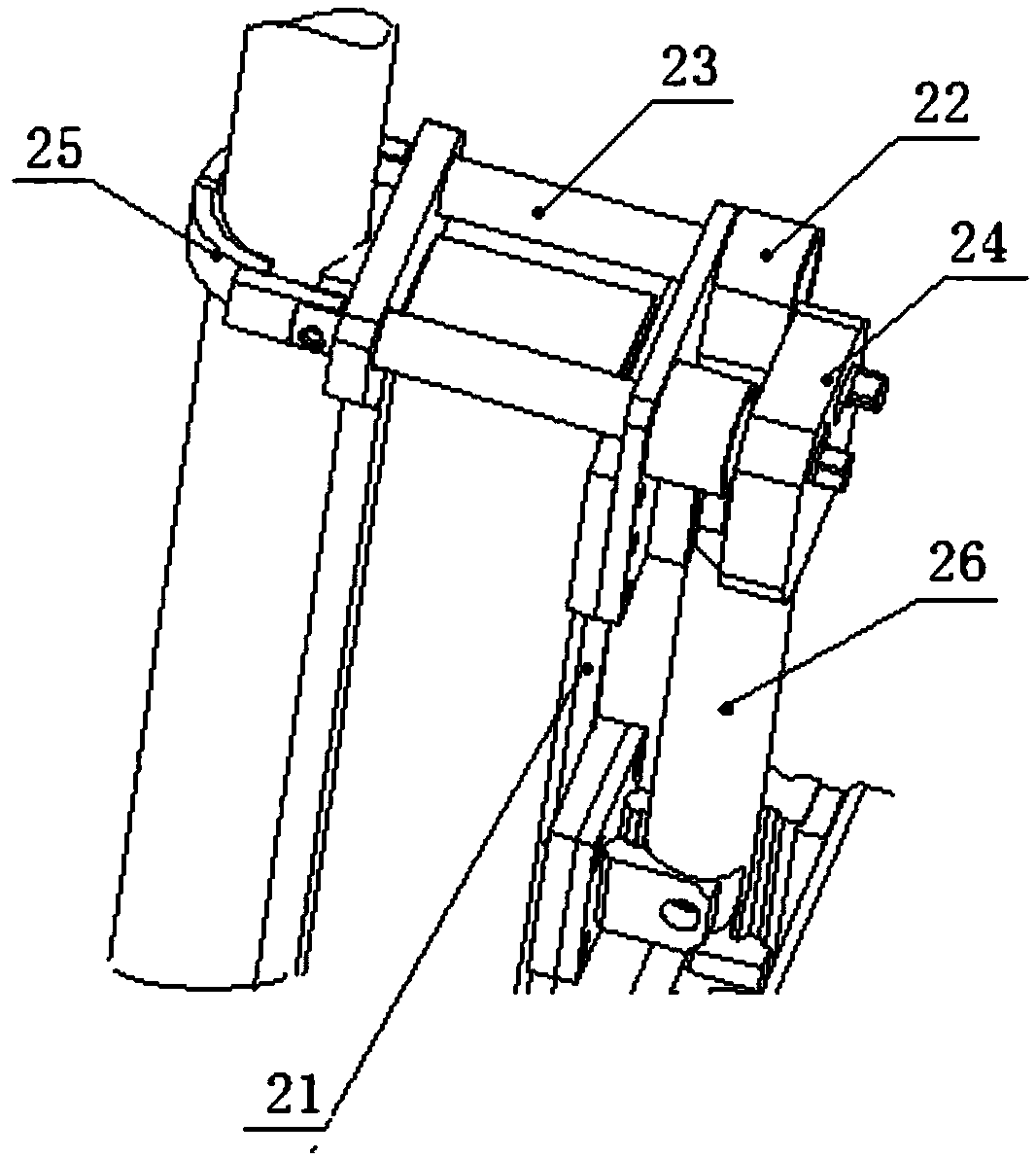

[0018] The present invention provides a pipe-loading manipulator for an automatic workover rig on an offshore platform, which includes a main arm 1 and a manipulator device 2, a top end seat 3 is provided on the top of the main arm 1, a rotary oil cylinder 4 is arranged inside the top end seat 3, and the main arm 1 There are slide rails 5 and lifting cylinders 6 on the back; two manipulator devices 2 are provided, one of which is hinged on the top seat 2 of the main arm 1 through a hinge shaft to form a rotating manipulator, and the rotating manipulator passes through the rotating oil cylinder 3 The control can rotate 180° around the top seat 3 and push the oil pipe 7 into the derrick; another manipulator device 2 is installed on the slide rail 5 on the back of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com