Methanol engine with dual-plasma generator

A technology of plasma generator and methanol engine, which is applied in the direction of machines/engines, engine components, combustion engines, etc., can solve the problems of decreased combustion stability of cylinders, increased emissions of hydrocarbons and formaldehyde, etc., and achieves the reduction of emissions and the effect Good, the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

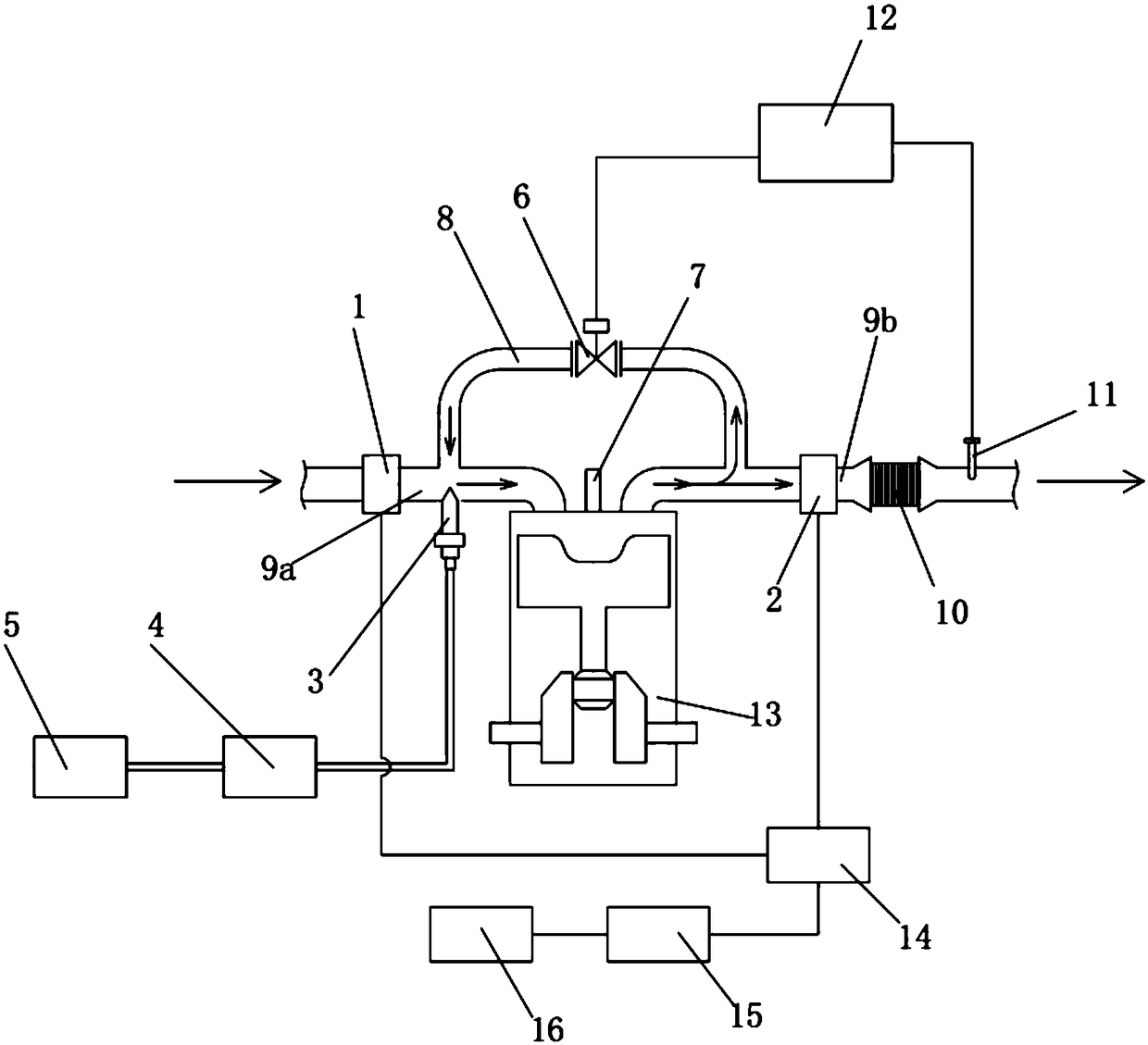

[0011] Depend on figure 1 Given, the present invention comprises engine cylinder 13, igniter 7, ECU12, methanol nozzle 3, methanol pressurized pump 4 and methanol storage tank 5, is respectively connected with intake main pipe 9a and exhaust pipe 9b communicating with it on the engine cylinder , the injection port of the methanol nozzle 3 extends into the intake manifold 9a, the inlet of the methanol nozzle 3 is connected to the outlet of the methanol booster pump 4 through the pipeline, and the inlet of the methanol booster pump 4 is connected to the outlet of the methanol storage tank 5 through the pipeline. An EGR valve 6 is installed on the exhaust gas recirculation pipe 8 between the gas main pipe 9a and the exhaust pipe 9b. The main pipe is equipped with a first plasma generator 1, and the connection point between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com