Blade locking device applied to wind electricity typhoon unit

A locking device and typhoon technology, which is applied in the control of wind turbines, wind power generation, wind turbines, etc., can solve the problems that the locking pin is easy to fall off, it is difficult to meet the strength requirement, and the locking angle is not fixed, so as to solve the structural form and size restrictions, meet the structural design requirements, and reduce the effect of installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

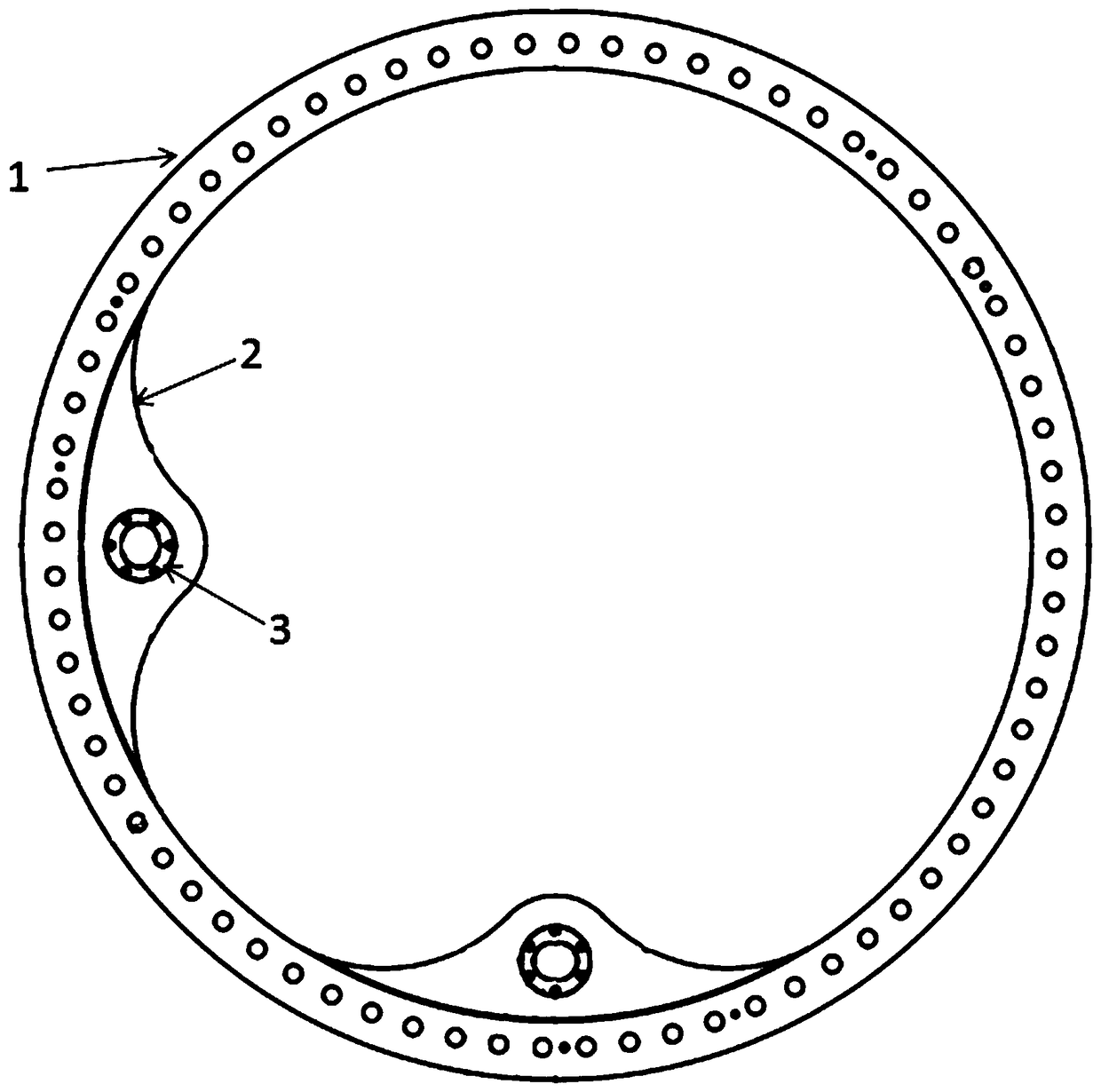

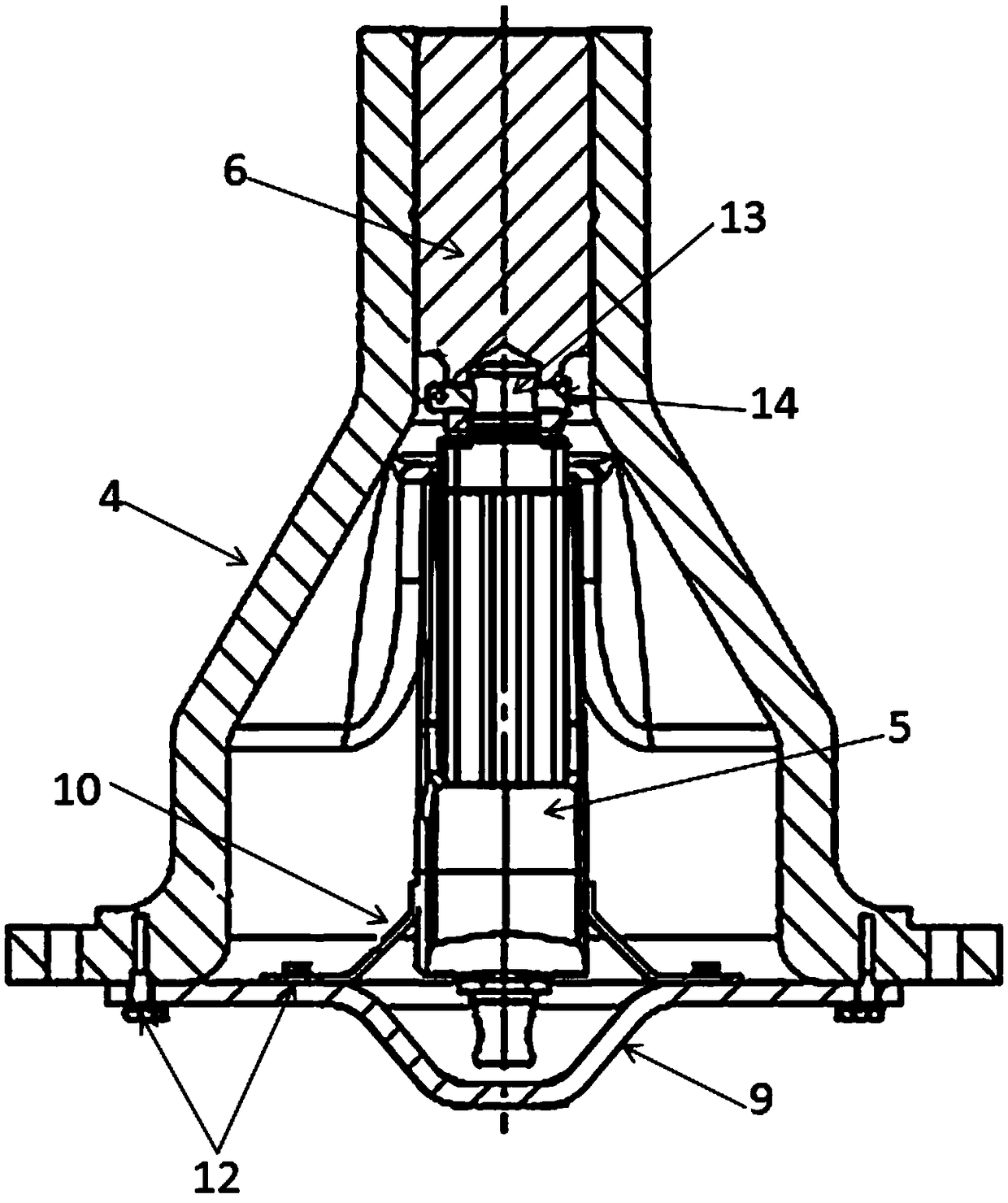

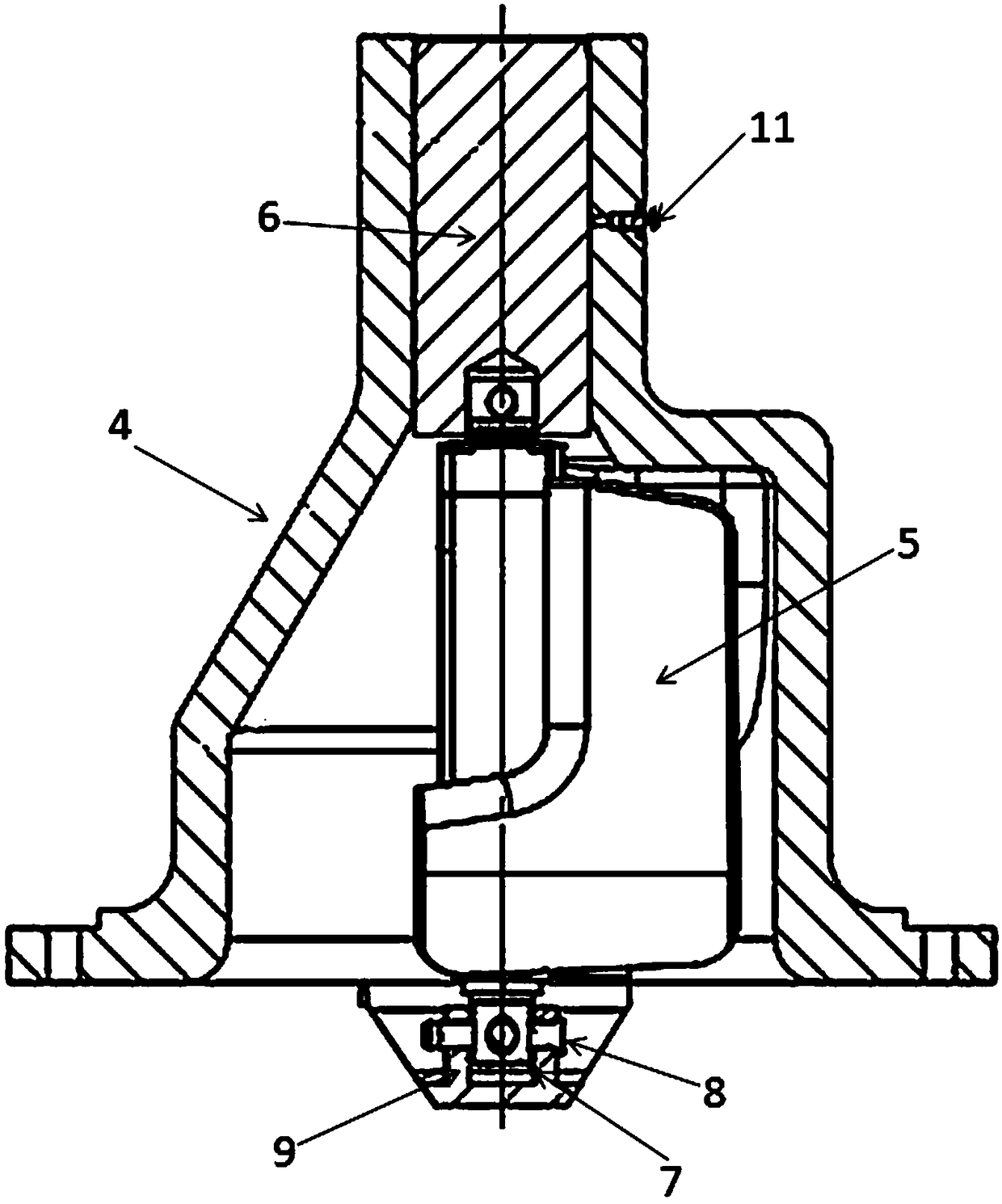

[0024] Such as Figure 1 to Figure 5 As shown, the present invention provides a blade locking device applied to a wind power generator set, which includes a locking disc 1 and an electric locking mechanism.

[0025] The locking disc 1 is installed between the blade bearing and the blade root of the fan unit of the wind station; the main body of the locking disc 1 is ring-shaped, and the inner edge of the ring is provided with a raised part 2 extending toward the center of the circle; A shaft sleeve 3 is installed in the through hole; the shaft sleeve 3 has a flange edge, and a circle of countersunk holes is arranged on the flange edge, and the shaft sleeve 3 is connected with the boss 2 with screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com