Characterization method of magnetic change of antiferromagnetic material under stress action, characterization device and preparation method thereof

A technology of stress action and ferromagnetic materials, which is applied in the direction of antiferromagnetic materials, magnetic materials, magnetic objects, etc., can solve the problems of regulation and control that are rarely studied, and antiferromagnetic materials are difficult to characterize and difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

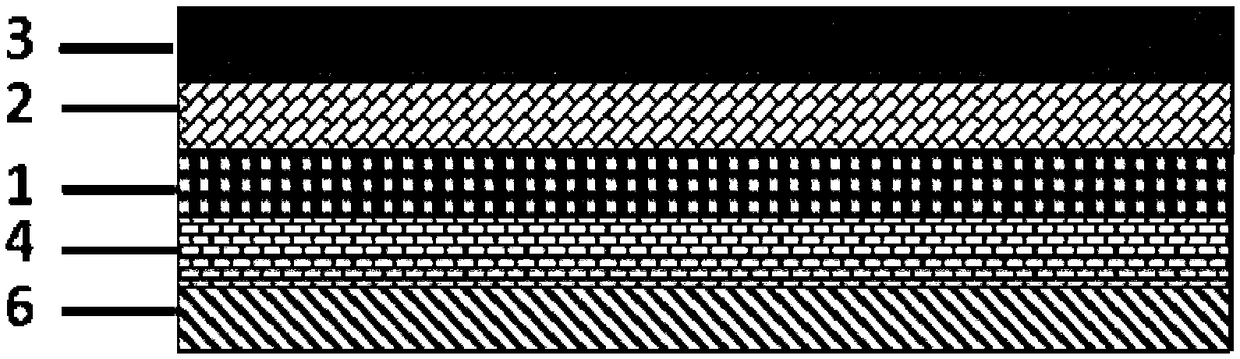

[0043] In this embodiment, the device structure that characterizes the magnetic change of the antiferromagnetic material under stress is as follows figure 1 As shown, it is a multi-layer film structure, and from bottom to top are: deformation generating device 6 , substrate 4 , antiferromagnetic material layer 1 , ferromagnetic material layer 2 , and nonmagnetic layer 3 .

[0044] The substrate 4 is a flexible substrate, which is made of commercially purchased flexible and high temperature resistant copper foil.

[0045] The antiferromagnetic material layer 1 is composed of FeRh, which exhibits antiferromagnetism at room temperature.

[0046] The ferromagnetic material layer 2 is composed of amorphous CoFeB.

[0047] The non-magnetic layer 3 is made of Ta material and serves as a protective layer.

[0048] The preparation method of this device is as follows:

[0049] Step 1: select a commercially purchased flexible and high-temperature-resistant high-purity copper foil as t...

Embodiment 2

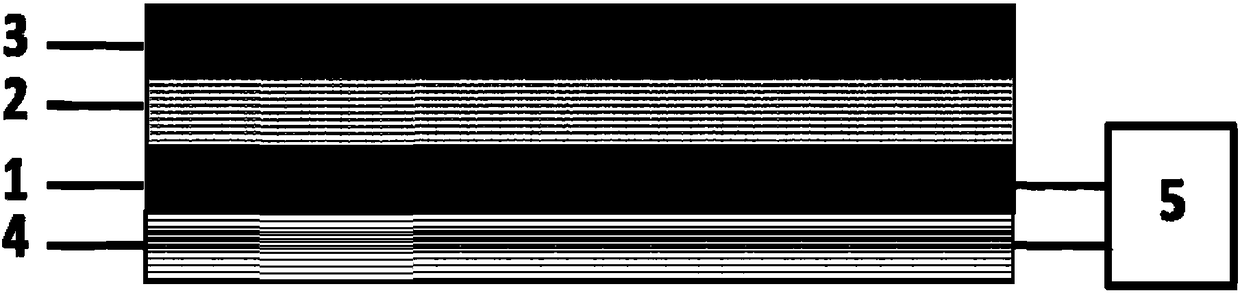

[0062] In this embodiment, the device structure that characterizes the magnetic change of the antiferromagnetic material under stress is as follows figure 2 As shown, it is a multi-layer film structure, from bottom to top: substrate 4 , antiferromagnetic material layer 1 , ferromagnetic material layer 2 , and nonmagnetic layer 3 , and the substrate 4 is connected to a voltage generating device 5 .

[0063] Substrate 4 adopts ferroelectric material Pb(Mg,Nb)O 3 -PbTiO 3 (PMNPT) composition, with inverse piezoelectric effect.

[0064] The antiferromagnetic material layer 1 is made of FeRh, and the FeRh material is antiferromagnetic at room temperature, and its magnetism changes under stress.

[0065] The ferromagnetic material layer 2 is composed of amorphous CoFeB.

[0066] The non-magnetic layer 3 is made of Ta material and serves as a protective layer.

[0067] The preparation method of this device is as follows:

[0068] Step 1: Select the ferroelectric material PMNPT ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com