Chemical preparation method of multiferroic BiFeO3 doped film

A multiferroic and thin-film technology, applied in chemical instruments and methods, inorganic chemistry, iron compounds, etc., can solve problems such as large leak conductance, unobservable remnant polarization, uncontrollable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

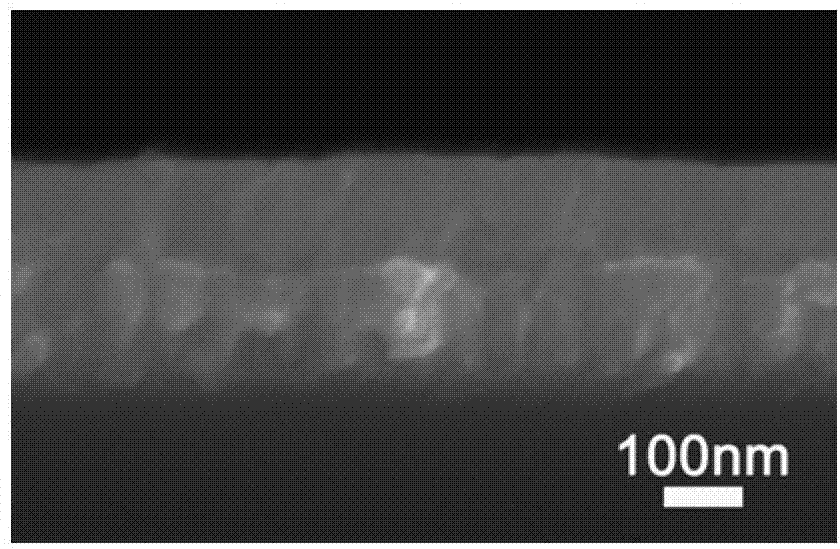

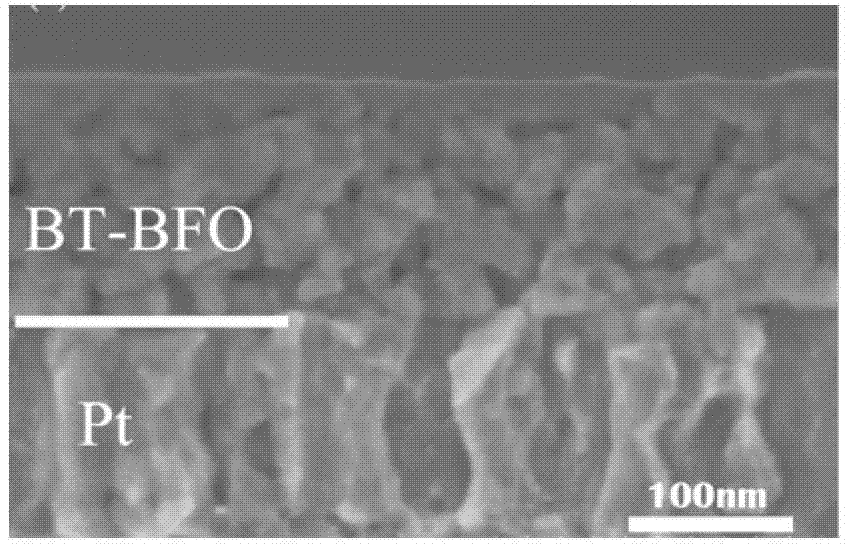

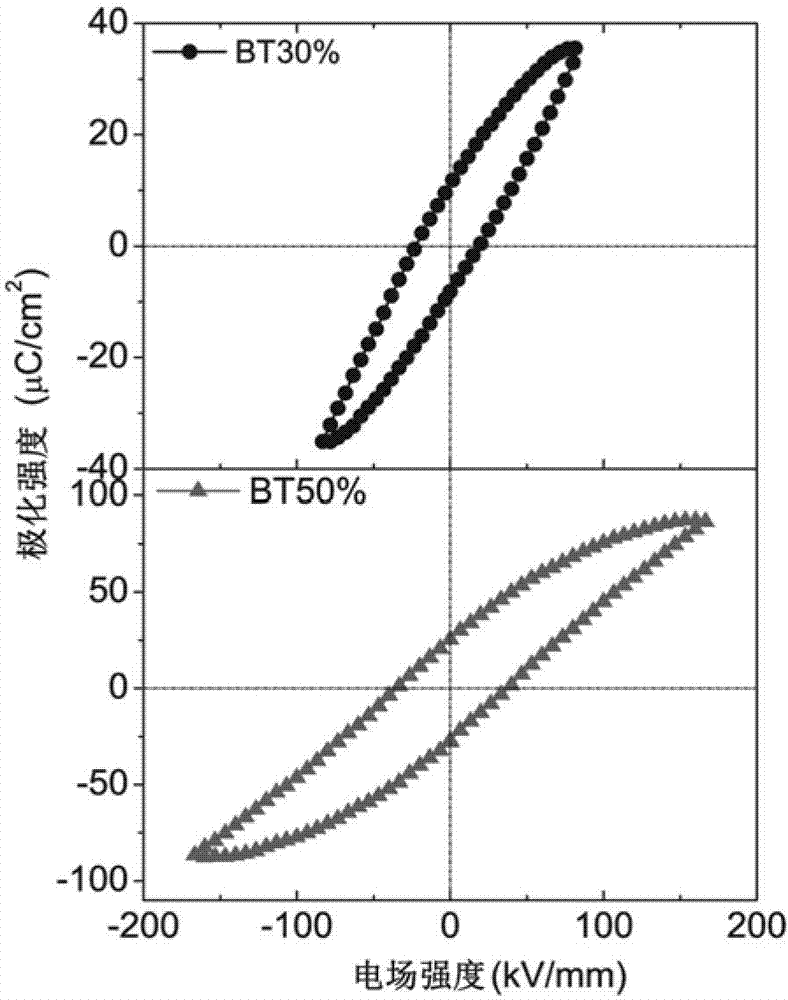

Image

Examples

Embodiment 1

[0022] Step 1: Ethylene glycol methyl ether and propionic acid are prepared as a solvent in a volume ratio of 3:1, which is used as the solvent in the subsequent sol preparation step.

[0023] Step 2: Parent phase BiFeO 3 Sol preparation: bismuth nitrate (Bi(NO 3 ) 3 ·6H 2 O), iron nitrate ((FeNO 3 ) 3 ·6H 2 O) and citric acid are dissolved in the solvent prepared in step 1 according to the cationic molar ratio of 1:1.5 to prepare BiFeO 3 The sol is BFO sol, and the sol concentration is 0.2mol / L.

[0024] Step 3: Doping phase BaTiO 3 Preparation of sol: After tetrabutyl titanate is dissolved in the solvent prepared in step 1 to form a stable sol, barium acetate (Ba(Ac) 2 ) and citric acid, tetrabutyl titanate, barium acetate and citric acid are formulated according to the cation molar ratio of 1:1.5 to form BaTiO 3 The sol is BTO sol, and the sol concentration is 0.2mol / L.

[0025] Step 4: the purchased Pt / Ti / SiO 2 The / Si substrate was cleaned sequentially with dei...

Embodiment 2

[0031] Step 1: Ethylene glycol methyl ether and propionic acid are prepared as a solvent in a volume ratio of 3:1, which is used as the solvent in the subsequent sol preparation step.

[0032] Step 2: Parent Phase BiFeO 3 Sol preparation: bismuth nitrate (Bi(NO 3 ) 3 ·6H 2 O), iron nitrate ((FeNO 3 ) 3 ·6H 2O) and citric acid are dissolved in the solvent prepared in step 1 according to the cationic molar ratio of 1:1.5 to prepare BiFeO 3 The sol is BFO sol, and the sol concentration is 0.2mol / L.

[0033] Step 3: Doping phase BaTiO 3 Preparation of sol: After tetrabutyl titanate is dissolved in the solvent prepared in step 1 to form a stable sol, barium acetate (Ba(Ac) 2 ) and citric acid, tetrabutyl titanate, barium acetate and citric acid are formulated according to the cation molar ratio of 1:1.5 to form BaTiO 3 The sol is BTO sol, and the sol concentration is 0.2mol / L.

[0034] Step 4: the purchased Pt / Ti / SiO 2 The / Si substrate was cleaned sequentially with deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| saturated polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com