l10-fept@ptbi2/bi core-shell nanoparticles and its one-step synthesis

A technology of l10-fept, core-shell structure, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as poor particle size uniformity, crystal structure defects, agglomeration, etc., to achieve particle growth The effect of good controllability, simple synthesis equipment and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] a L1 0 -FePt@PtBi 2 The one-step synthetic method of / Bi core-shell structure nanoparticle, comprises the following steps:

[0043] step 1:

[0044] Put the precursor [0.25mmol, 98.3.mg] of platinum acetylacetonate, [0.25mmol, 88.3mg] of iron acetylacetonate, [0.3mmol, 115.8mg] of bismuth acetate into a 100mL three-necked bottle, namely the Bi precursor The molar content of the body is 60% of the total molar content of Fe and Pt precursors, add [0.75mmol, 193.8mg] reducing agent 1,2-hexadecanediol, 10mL of solvent hexadecylamine, at 70 ℃ with a stirring bar Stir to mix the precursor with the solvent and the reducing agent evenly to obtain a mixed liquid;

[0045] Raise the temperature of the mixture to 110°C and stir for 30 minutes to remove water, then add 0.5mL of oleic acid and 0.5mL of oleylamine, stir evenly, raise the temperature to 360°C at 6°C / min, keep it warm for 3h, and cool to room temperature with the furnace. to obtain a suspension.

[0046] Step 2:

...

Embodiment 2

[0053] a L1 0 -FePt@PtBi 2 The one-step synthetic method of / Bi core-shell structure nanoparticle, with embodiment 1, difference is:

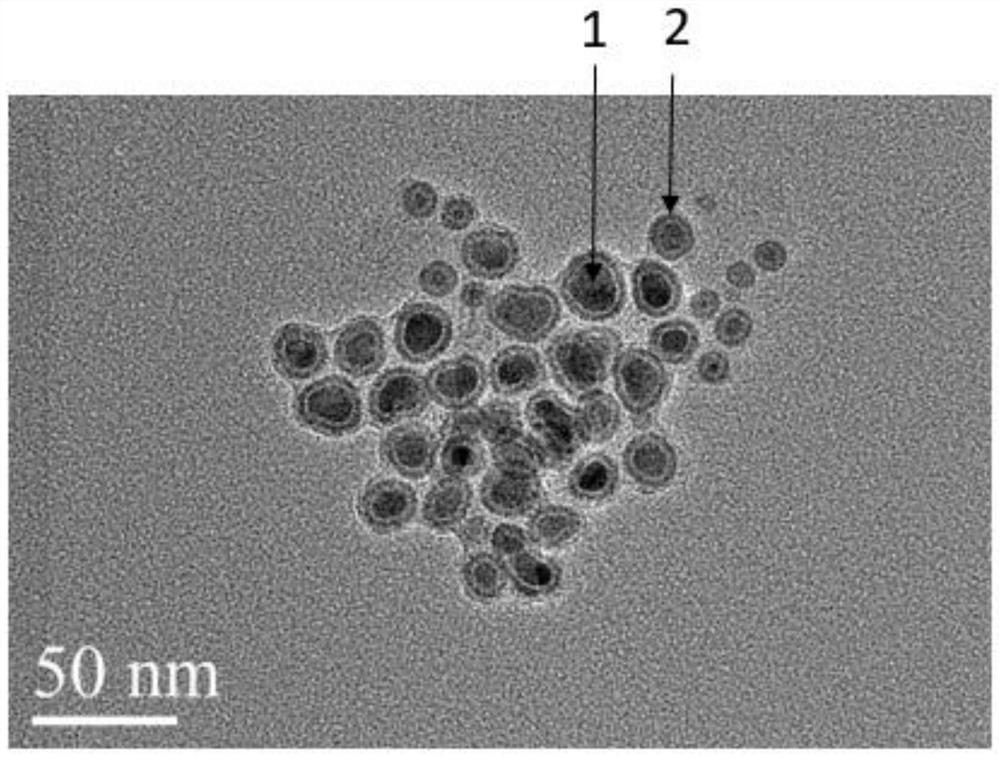

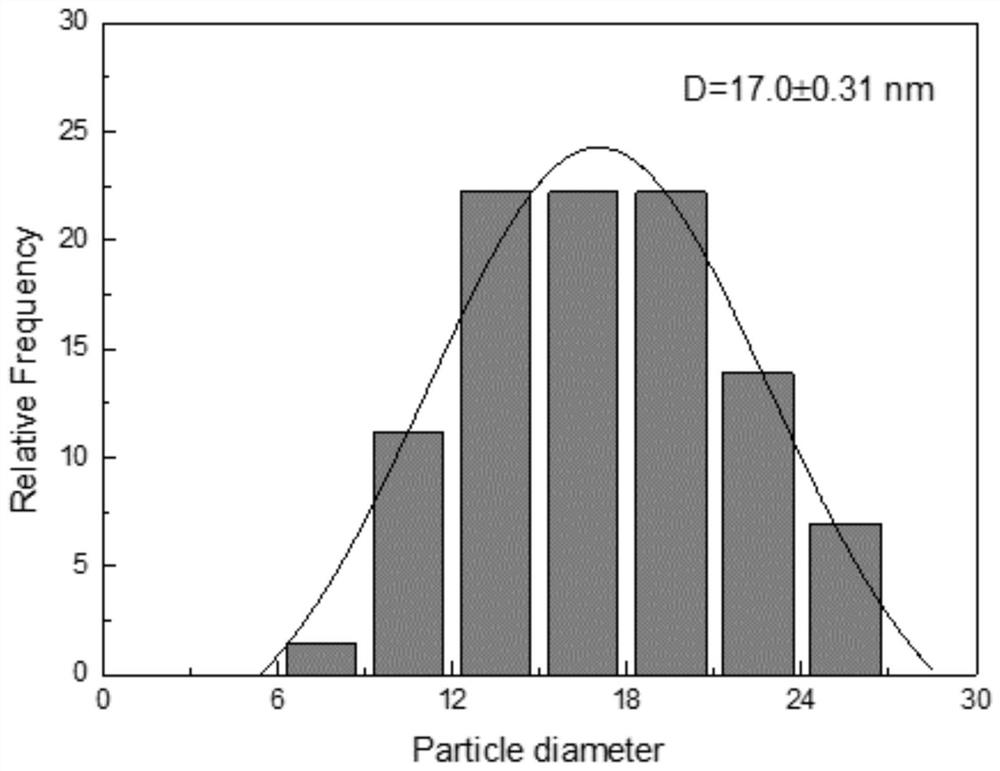

[0054] Precursor Fe(acac) 2 、Pt(acac) 2 、Bi(Ac) 3 The molar ratio is 0.25:0.25:0.2, that is, the precursor adopts platinum acetylacetonate of [0.25mmol, 98.3.mg], iron acetylacetonate of [0.25mmol, 88.3mg], bismuth acetate of [0.2mmol, 77.2mg], The molar content of the Bi precursor is 40% of the total molar content of the Fe and Pt precursors. The prepared L1 0 -FePt@PtBi 2 The atomic percent of / Bi core-shell structure nanoparticle is Fe:Pt:Bi=44:33:23at%, gained L1 0 -FePt@PtBi 2 / Bi core-shell structure nanoparticles TEM image Figure 6 As shown, the statistical average particle diameter size is 11.5 ± 0.27nm, the inner core diameter is 6.3 ± 0.64nm, and its particle size distribution histogram is shown in Figure 7 As shown, L1 0 -FePt@PtBi 2 / Bi core-shell structure nanoparticles have a coercive force of 12kOe (hysteresis loop ...

Embodiment 3

[0056] a L1 0 -FePt@PtBi 2 The one-step synthetic method of / Bi core-shell structure nanoparticle, with embodiment 1, difference is:

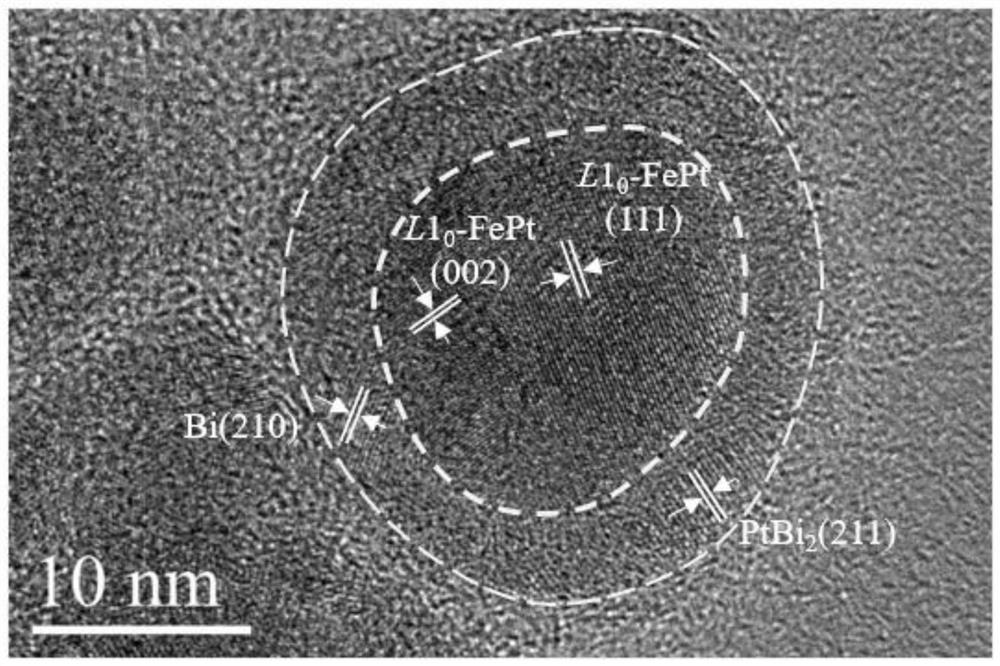

[0057] Precursor Fe(acac) 2 、Pt(acac) 2 、Bi(Ac) 3 The molar ratio is 0.25:0.25:0.35, that is, the precursor adopts platinum acetylacetonate of [0.25mmol, 98.3.mg], iron acetylacetonate of [0.25mmol, 88.3mg], bismuth acetate of [0.35mmol, 135.1mg], The molar content of the Bi precursor is 70% of the total molar content of the Fe and Pt precursors.

[0058] The prepared L1 0 -FePt@PtBi 2 / Bi core-shell structure nanoparticles transmission electron microscope image see Figure 8 , its atomic percentage is Fe:Pt:Bi=40:27:33at%, the obtained L1 0 -FePt@PtBi 2 / Bi core-shell structure nanoparticles have a coercive force of 15.99kOe (hysteresis loop such as Figure 4 Shown), its X-ray diffraction pattern is shown in Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com