Method for loading gentamicin by using TiO2 nanotube coating in situ synthesized on Ti surface

A technology of in-situ synthesis of gentamicin, applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc., can solve the problems of limited loading and release characteristics, antibiotics cannot be blended, etc., and achieve the purpose of inhibiting the initial adhesion of bacteria Attachment, reduce the formation of biofilm, and promote the effect of osseointegration with the surrounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

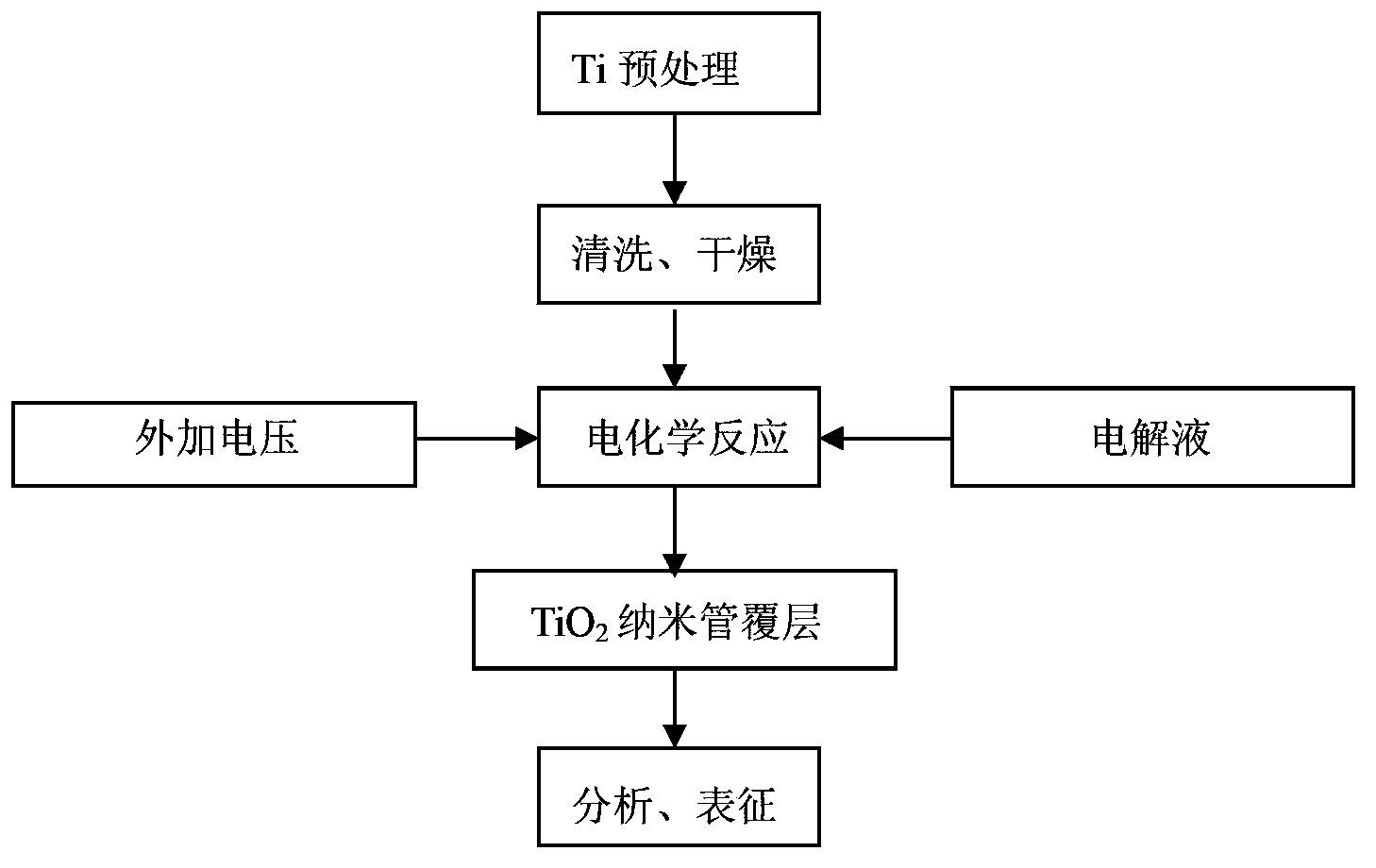

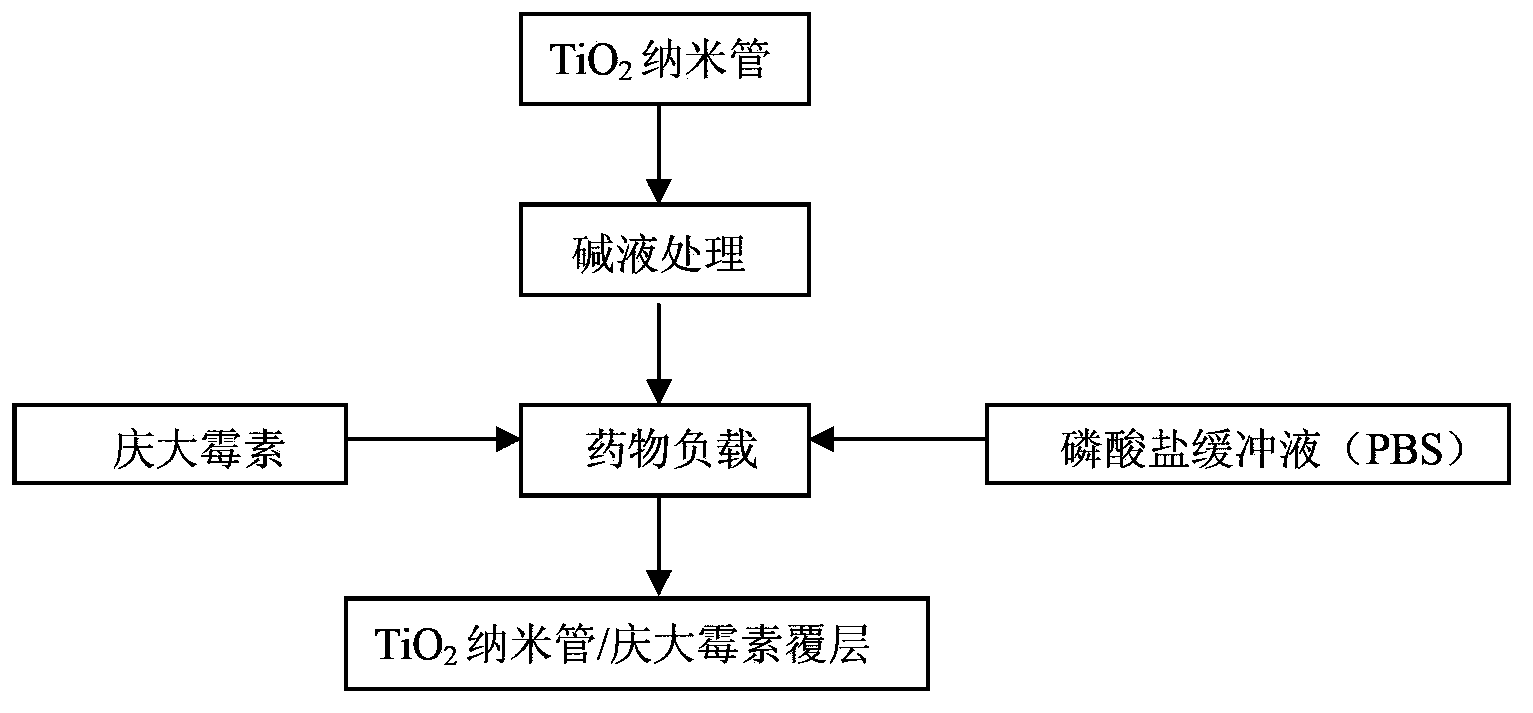

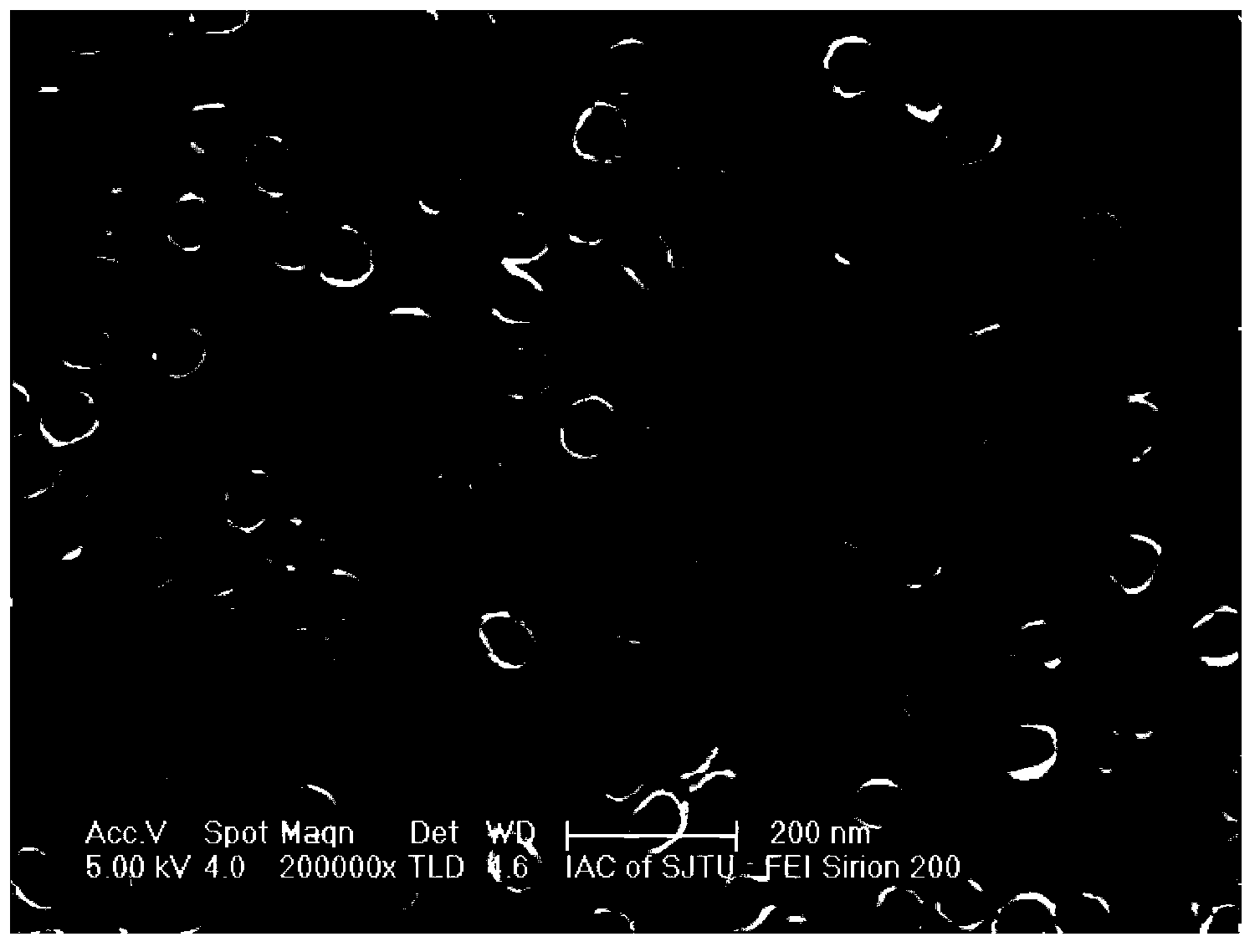

[0030] Such as Figure 1-2 As described, a TiO synthesized in situ on the Ti surface 2 The method of nanotube coating loading gentamicin, first prepare TiO on the pretreated titanium substrate by anodic oxidation method 2 nanotube coating, and then the prepared TiO 2 The nanotubes were immersed in alkaline solution, and then deposited on TiO by co-precipitation 2 The nanotube coating is loaded with gentamicin, and the specific steps are as follows:

[0031] 1) TiO 2 Preparation of nanotubes: Cut the pure titanium sheet (purity > 99.9%) into 1.5cm×1.5em size, 1mm thick substrate, polish with 400 mesh, 1000 mesh, 1500 mesh metallographic sandpaper successively, and then place Ultrasonic cleaning with ethanol and acetone, and drying for later use. Connect the ground and cleaned Ti sheet to the anode, connect the Pt sheet to the cathode, mix 20ml distilled water, 180ml ethylene glycol, 0.09M NH 4 F was mixed as electrolyte, and reacted at an oxidation voltage of 20V for 30mi...

Embodiment 2

[0036] 1) TiO 2 Preparation of nanotubes: Cut pure titanium sheet (purity>99.9%) into 1.5cm×1.5cm size, 1mm thick substrate, polish with 400 mesh, 1000 mesh, 1500 mesh metallographic sandpaper successively, then place Ultrasonic cleaning with ethanol and acetone, and drying for later use. Connect the ground and cleaned Ti sheet to the anode, connect the Pt sheet to the cathode, mix 20ml of distilled water, 180ml of ethylene glycol, and 0.05M NH4F as the electrolyte, and react at an oxidation voltage of 30V for 120min. Carried out in a fume hood, the electrolytic cell was placed in a magnetic stirrer for 10r / min magnetic stirring. After the reaction, the Ti sheet was taken out and washed with distilled water.

[0037] 2) Heat treatment of the sample: in a vacuum muffle furnace, the temperature was raised from room temperature to 550°C at a rate of 5°C / min, kept for 2 hours, and then the temperature was lowered with the furnace.

[0038] 3) Loading of gentamicin: immerse the ...

Embodiment 3

[0041] 1) TiO 2 Preparation of nanotubes: Cut pure titanium sheet (purity>99.9%) into 1.5cm×1.5cm size, 1mm thick substrate, polish with 400 mesh, 1000 mesh, 1500 mesh metallographic sandpaper successively, then place Ultrasonic cleaning with ethanol and acetone, and drying for later use. Connect the ground and cleaned Ti sheet to the anode, connect the Pt sheet to the cathode, mix 60ml of distilled water, 140ml of ethylene glycol, and 0.13M NH4F as the electrolyte, and react at an oxidation voltage of 60V for 30min. Carried out in a fume hood, the electrolytic cell was placed in a magnetic stirrer for 10r / min magnetic stirring. After the reaction, the Ti sheet was taken out and washed with distilled water.

[0042] 2) Heat treatment of the sample: in a vacuum muffle furnace, the temperature was raised from room temperature to 450°C at a rate of 2°C / min, kept for 4 hours, and then cooled with the furnace.

[0043] 3) Loading of gentamicin: the prepared sample was immersed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com