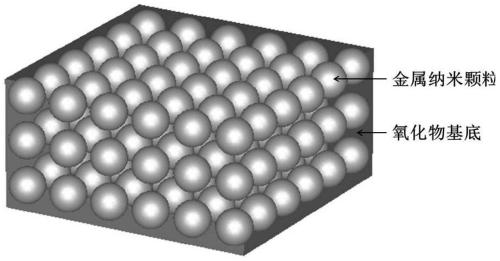

Infrared stealth metal nanoparticle metamaterial composite film compatible with visible light stealth and preparation method thereof

A technology of metal nanoparticles and composite films, applied in metal material coating technology, optics, optical components, etc., can solve the problems of low emissivity, unfavorable visible light stealth compatibility, etc., and achieve good quality, good controllability of film growth, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

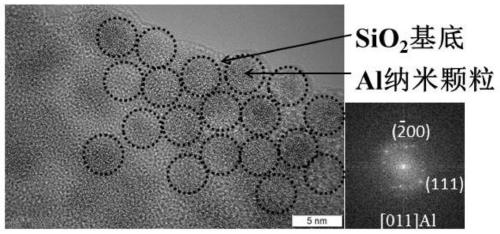

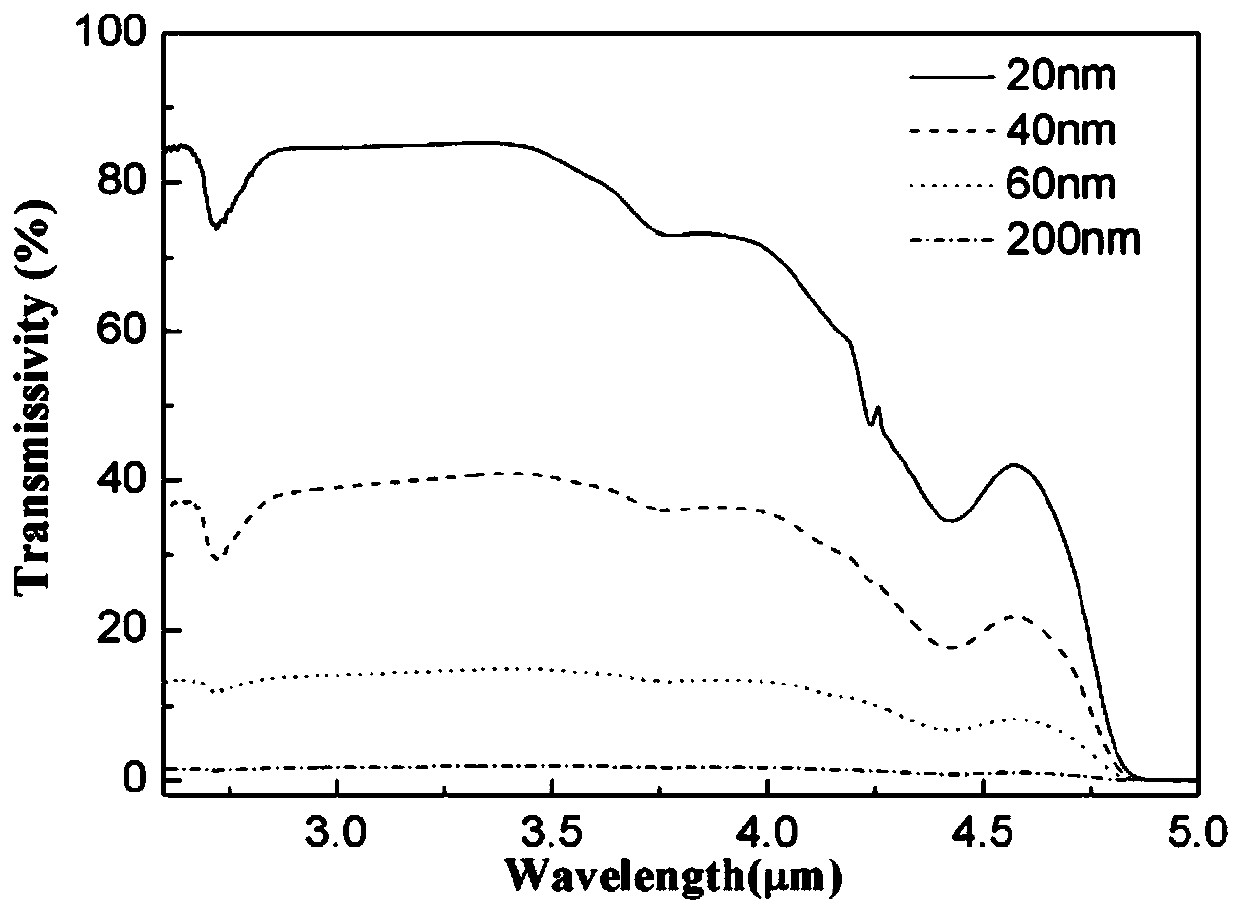

[0028] Metal Al is sputtered by DC power, and SiO is sputtered by RF power 2 , Al-SiO 2 The preparation method of the nanoparticle supermaterial composite film comprises the following steps:

[0029] Step 1, substrate selection and pretreatment:

[0030] Select a polished silicon wafer with a surface roughness of less than 0.5nm and a crystal orientation of (100), ultrasonically clean the silicon wafer in acetone, deionized water, and alcohol solution for 15 minutes, and dry it with a high-purity argon high-pressure spray gun;

[0031] Step 2, target preparation:

[0032] The purity of the metal Al target used is ≥99.99%, and the SiO used 2 Target purity ≥ 99.999%, put the two targets into two target positions respectively, and close the target baffle;

[0033] Step 3, composite membrane preparation:

[0034] Place the substrate processed in step 1 on the sample stage. When the vacuum degree of the coating chamber is better than 3.2×10 -3 When Pa, enter Ar gas, the pres...

Embodiment 2

[0039] Metal Ti is sputtered by DC power and SiO is sputtered by RF power 2 , Ti-SiO 2 The preparation method of the nanoparticle supermaterial composite film comprises the following steps:

[0040] Step 1, substrate selection and pretreatment:

[0041] Select a polished silicon wafer with a surface roughness of less than 0.5nm and a crystal orientation of (100), ultrasonically clean the silicon wafer in acetone, deionized water, and alcohol solution for 15 minutes, and dry it with a high-purity argon high-pressure spray gun;

[0042] Step 2, target preparation:

[0043] The purity of the metal Ti target used is ≥99.99%, and the SiO used 2 Target purity ≥ 99.999%, put the two targets into two target positions respectively, and close the target baffle;

[0044] Step 3, composite membrane preparation:

[0045] Place the substrate processed in step 1 on the sample stage. When the vacuum degree of the coating chamber is better than 3.2×10 -3 When Pa, enter Ar gas, the press...

Embodiment 3

[0048] Alloy TiAl is sputtered by DC power, and SiO is sputtered by RF power 2 , TiAl-SiO 2 The preparation method of the nanoparticle supermaterial composite film comprises the following steps:

[0049] Step 1, substrate selection and pretreatment:

[0050] Select a polished silicon wafer with a surface roughness of less than 0.5nm and a crystal orientation of (100), ultrasonically clean the silicon wafer in acetone, deionized water, and alcohol solution for 15 minutes, and dry it with a high-purity argon high-pressure spray gun;

[0051] Step 2, target preparation:

[0052] The purity of the metal TiAl target used is ≥99.99%, and the SiO used 2 Target purity ≥ 99.999%, put the two targets into two target positions respectively, and close the target baffle;

[0053] Step 3, composite membrane preparation:

[0054] Place the substrate processed in step 1 on the sample stage. When the vacuum degree of the coating chamber is better than 3.2×10 -3 When Pa, enter Ar gas, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com