Low-dimension method for nano-wires

A technology of nanowires and metal nanowires, which is applied in the preparation of inorganic/organic nanomaterials and the field of low-dimensional nanowires. It can solve the problems of complex process, high cost, and difficulty in large-scale production, and achieve simple preparation process and extremely high purity. High, fully converting results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Disperse silver nanowires with a diameter of 200 nanometers and a length of 30 micrometers in the solvent N-methylpyrrolidone, set a temperature of 100°C and stir for 1 hour, and subject the resulting sample to ultrasonic treatment with 300W ultrasonic power for 2 hours to obtain silver nanowires. particle.

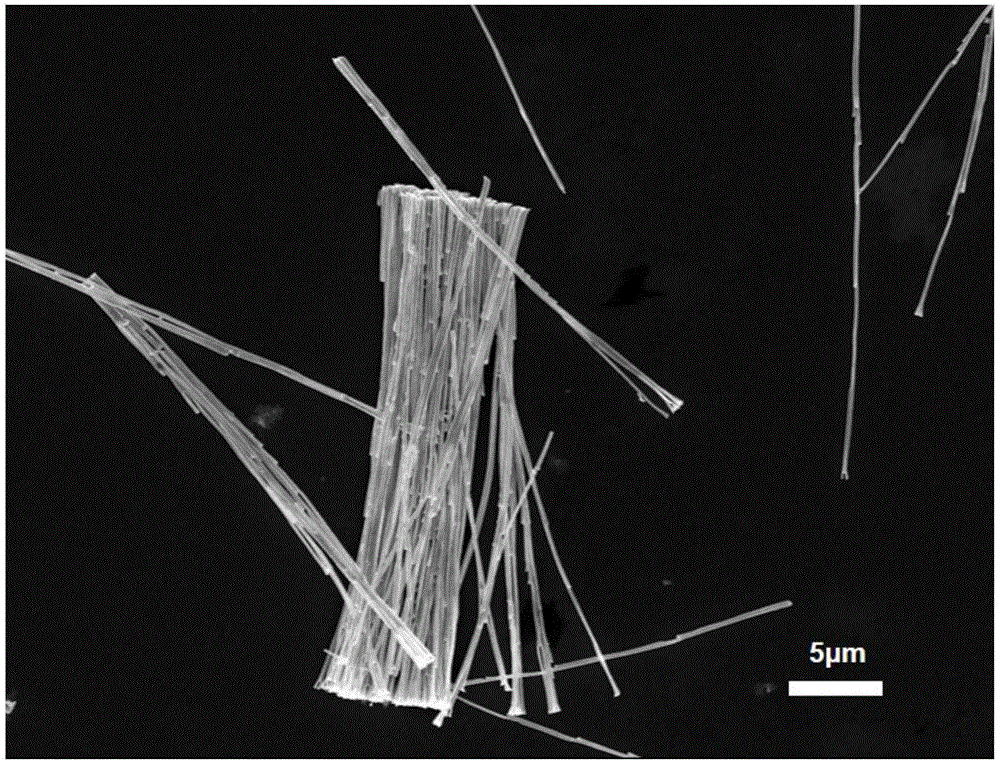

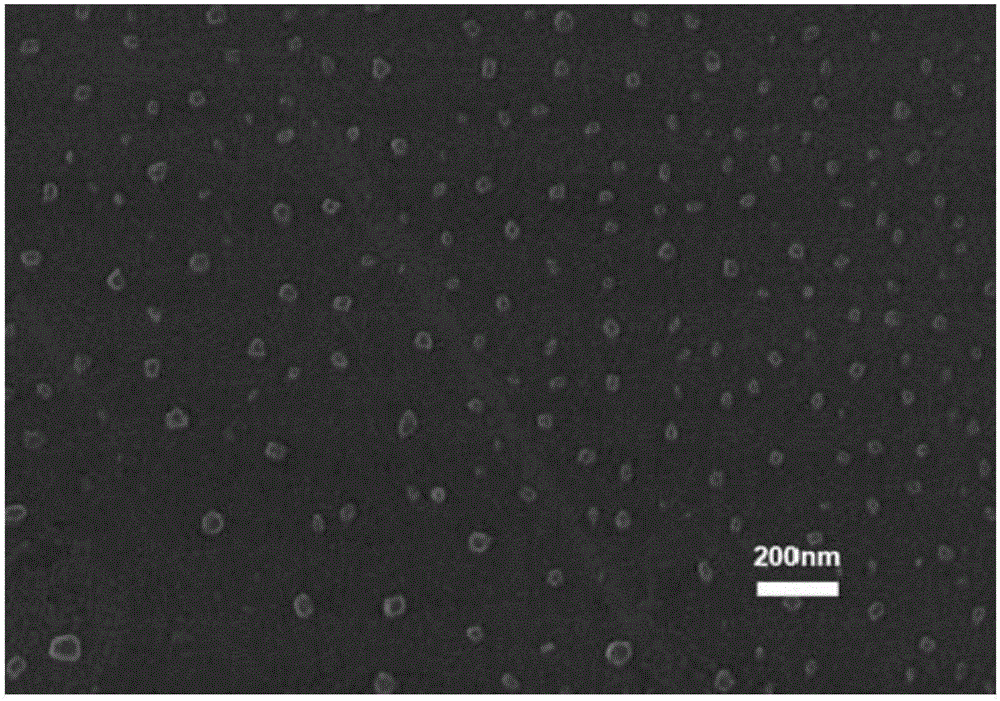

[0053] figure 1 It is a scanning electron micrograph of the silver nanowires in Example 1, from figure 1 It can be seen that the length of the silver nanowire is 30 microns. figure 2 This is a scanning electron micrograph of the silver nanoparticles obtained in Example 1. figure 2 It can be seen that the silver nanowires have been completely converted into silver nanoparticles, and the size of the converted silver nanoparticles is about 30 nanometers, and the particle size is uniform.

Embodiment 2

[0055] Disperse ferroplatin nanowires with a diameter of 1000 nanometers and a length of 100 micrometers in a solvent formamide, set the temperature to 200 ℃ and stir for 12 hours, and subject the resulting sample to ultrasonic power of 500W for 0.5h to obtain ferroplatin nanowires. particle.

Embodiment 3

[0057] Disperse silicon nanowires with a diameter of 10 nanometers and a length of 1 micron in the solvent N,N-dimethylacetamide, set the temperature at 20℃ and stir for 48 hours. The resulting sample is ultrasonicated with a 100W ultrasonic power ultrasonic probe for 10 hours. , That is, silicon nanoparticles are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com