Method for preparing porous polymer film by bubble template method

A technology of porous polymer and template method, which is applied in chemical instruments and methods, membranes, membrane technology, etc., to achieve the effects of simple and flexible device construction, low price, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

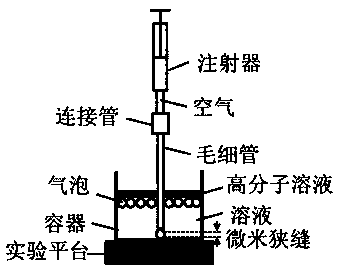

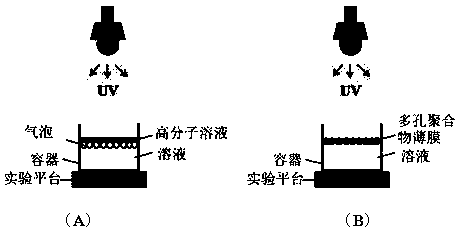

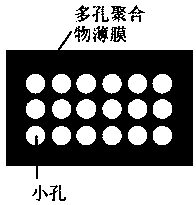

[0039] Such as Figure 1~3 As shown, first prepare the continuous (external) phase solution of the lower layer, mainly dissolving 2.59 g sodium dodecyl sulfate SDS in 99.86 g deionized water, heating and stirring at low temperature (30°C, 350 rpm) for 2 h to form a uniform solution . Take 1g of the prepared SDS solution and add 4g of pure glycerol, and vortex for 5min to make it evenly mixed. Then this solution was moved into a square transparent glass pool (25mm×25mm×25mm), and a small amount of prepared ethoxylated trimethylolpropane triacrylate (ETPTA) solution containing 1wt% photoinitiator was added to it, And as the polymer solution of the upper layer; at the same time, draw 500 μL of air into the syringe of the syringe pump (to confirm that the device is well sealed), and connect the quartz capillary (50 μm inner diameter, 146 μm outer diameter) to the syringe.

[0040] Insert the prepared 5cm-long quartz capillary vertically into the glass cell containing the continu...

Embodiment 2

[0042] First, prepare the continuous (external) phase solution of the lower layer, mainly dissolving 2.59 g sodium dodecyl sulfate SDS in 99.86 g deionized water, heating and stirring at low temperature (30°C, 350 rpm) for 2 h to form a uniform solution. Take 1 g of the prepared SDS solution and add 4 g of pure glycerol, and vortex for 5 min to make it evenly mixed. Then this solution was moved into a square transparent glass cell (25mm×25mm×25mm), and a small amount of prepared ethoxylated trimethylolpropane triacrylate (ETPTA) solution containing 1 wt% photoinitiator was added to it , and used as the polymer solution of the upper layer; at the same time pump 500 μL nitrogen (N 2 ) into the syringe of the syringe pump (make sure the seal of the device is good), and connect the quartz capillary (50 μm inner diameter, 146 μm outer diameter) to the syringe.

[0043] Insert the prepared 5 cm long quartz capillary vertically into the glass pool containing the continuous phase, an...

Embodiment 3

[0045] First prepare the continuous (external) phase solution of the lower layer, mainly adding 4 g of surfactant PF-decanol to 16 g of fluorocarbon oil FC-40, and shake it on a shaker for 24 h to make it evenly mixed. Then move this solution into a square transparent glass cell (25mm×25mm×25mm), and take a small amount of prepared UV-curable monomer N-N-isopropylacrylamide (NIPAM) containing 5 wt% and 2.5 wt% The aqueous solution of the cross-linking agent N-N-dimethylbisacrylamide (MBA) was added to it as the polymer solution of the upper layer; at the same time, 500 μL of air was drawn into the syringe of the syringe pump (to confirm that the device is well sealed), and Connect a quartz capillary (50 µm inner diameter, 146 µm outer diameter) to the syringe.

[0046] Insert the prepared 5 cm long quartz capillary vertically into the glass pool containing the continuous phase, and adjust the distance between the capillary mouth and the bottom of the glass pool ( d g ), so t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com