Preparation method of three-dimensional carbon network coated Ni2P nano particle composite material

A nanoparticle and composite material technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of large size of nickel phosphide material, poor process controllability, complex preparation process, etc., to achieve good consistency, Beneficial for mass production, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

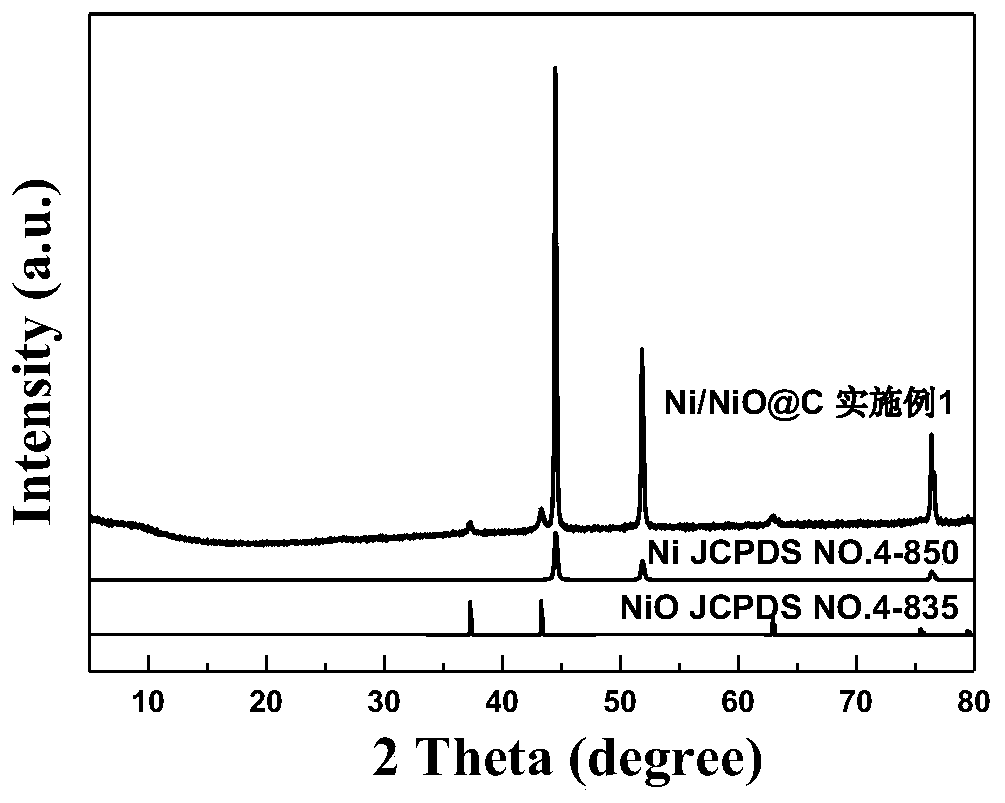

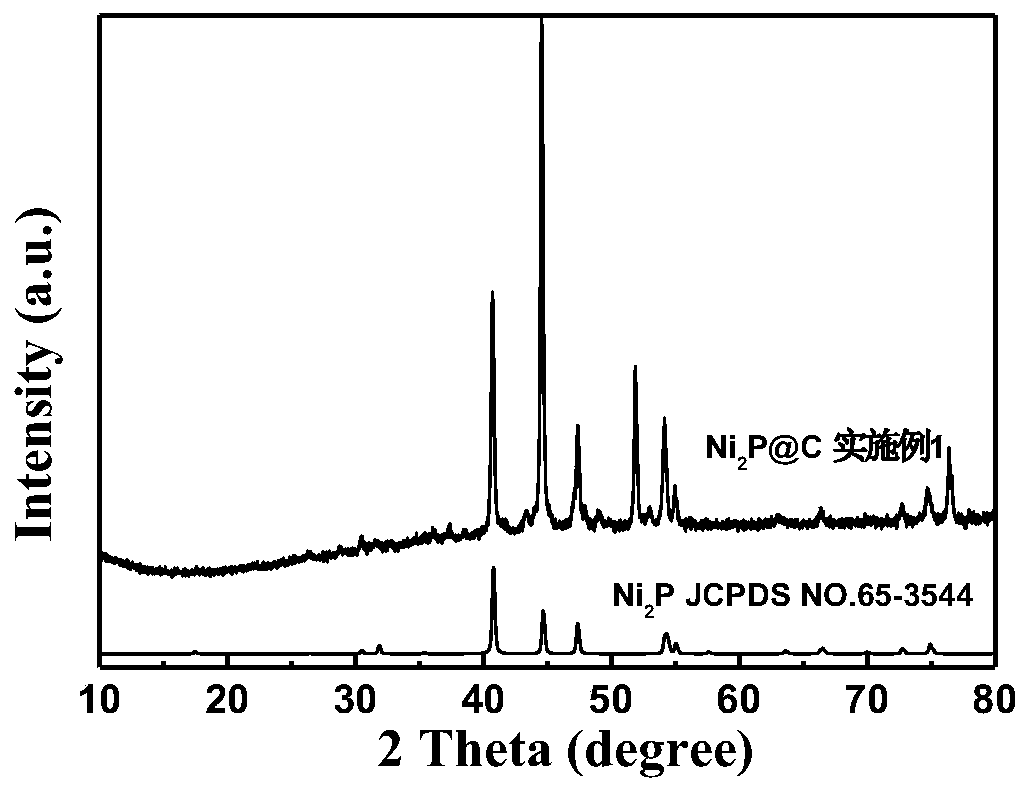

Embodiment 1

[0026] Add 0.8 g of citric acid monohydrate and 0.4 g of nickel nitrate hexahydrate to 20 ml of deionized water, sonicate for 30 minutes, then add 7 g of sodium chloride and continue to sonicate for 30 minutes. After being frozen with liquid nitrogen, it was dried in a freeze dryer for 48 h, and then placed in Ar 2 Calcined in the atmosphere, the calcination temperature is 700 °C, and the heating rate is 5 °C min -1 , the calcination time was 2h, and then the NaCl was washed off with deionized water to obtain the Ni / NiO@C precursor. Weigh 100mg of Ni / NiO@C precursor and 500mg of sodium hypophosphite, and put them in two independent porcelain boats respectively. 2 Calcined in atmosphere for 2h to get Ni 2 P / C composite material, the calcination temperature is 350℃, and the heating rate is 2℃min -1 .

Embodiment 2

[0028] Add 0.8 g of citric acid monohydrate and 0.2 g of nickel nitrate hexahydrate to 20 ml of deionized water, sonicate for 30 min, then add 7 g of sodium chloride and continue sonicating for 30 min. After being frozen with liquid nitrogen, it was dried in a freeze dryer for 48 h, and then placed in Ar 2 Calcined in the atmosphere, the calcination temperature is 700 °C, and the heating rate is 5 °C min -1 , the calcination time was 2h, and then the NaCl was washed off with deionized water to obtain the Ni / NiO@C precursor. Weigh 100mg of Ni / NiO@C precursor and 500mg of sodium hypophosphite, and put them in two independent porcelain boats respectively. 2 Calcined in atmosphere for 2h to get Ni 2 P / C composite material, the calcination temperature is 350℃, and the heating rate is 2℃min -1 .

Embodiment 3

[0030] Add 0.8 g of citric acid monohydrate and 0.4 g of nickel nitrate hexahydrate to 20 ml of deionized water, sonicate for 30 minutes, then add 7 g of sodium chloride and continue to sonicate for 30 minutes. After being frozen with liquid nitrogen, it was dried in a freeze dryer for 48 h, and then placed in Ar 2 Calcined in the atmosphere, the calcination temperature is 700 °C, and the heating rate is 5 °C min -1 , the calcination time is 2h, then wash off the sodium chloride with deionized water, and then use 2molL -1 The Ni / NiO@C precursor was obtained by washing with HCl at room temperature for 12 h. Weigh 100mg of Ni / NiO@C precursor and 500mg of sodium hypophosphite, and put them in two independent porcelain boats respectively. 2 Calcined in atmosphere for 2h to get Ni 2 P / C composite material, the calcination temperature is 350℃, and the heating rate is 2℃min -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com