Method for preparing ferroferric oxide magnetic layer on stainless steel fiber surface

A technology of ferric tetroxide and fiber surface, which can be used in coatings, electrolytic coatings, etc., can solve problems such as the effect of shielding performance and low electrical conductivity, and achieve convenient operation, good electromagnetic comprehensive performance, coating morphology and magnetic properties. controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

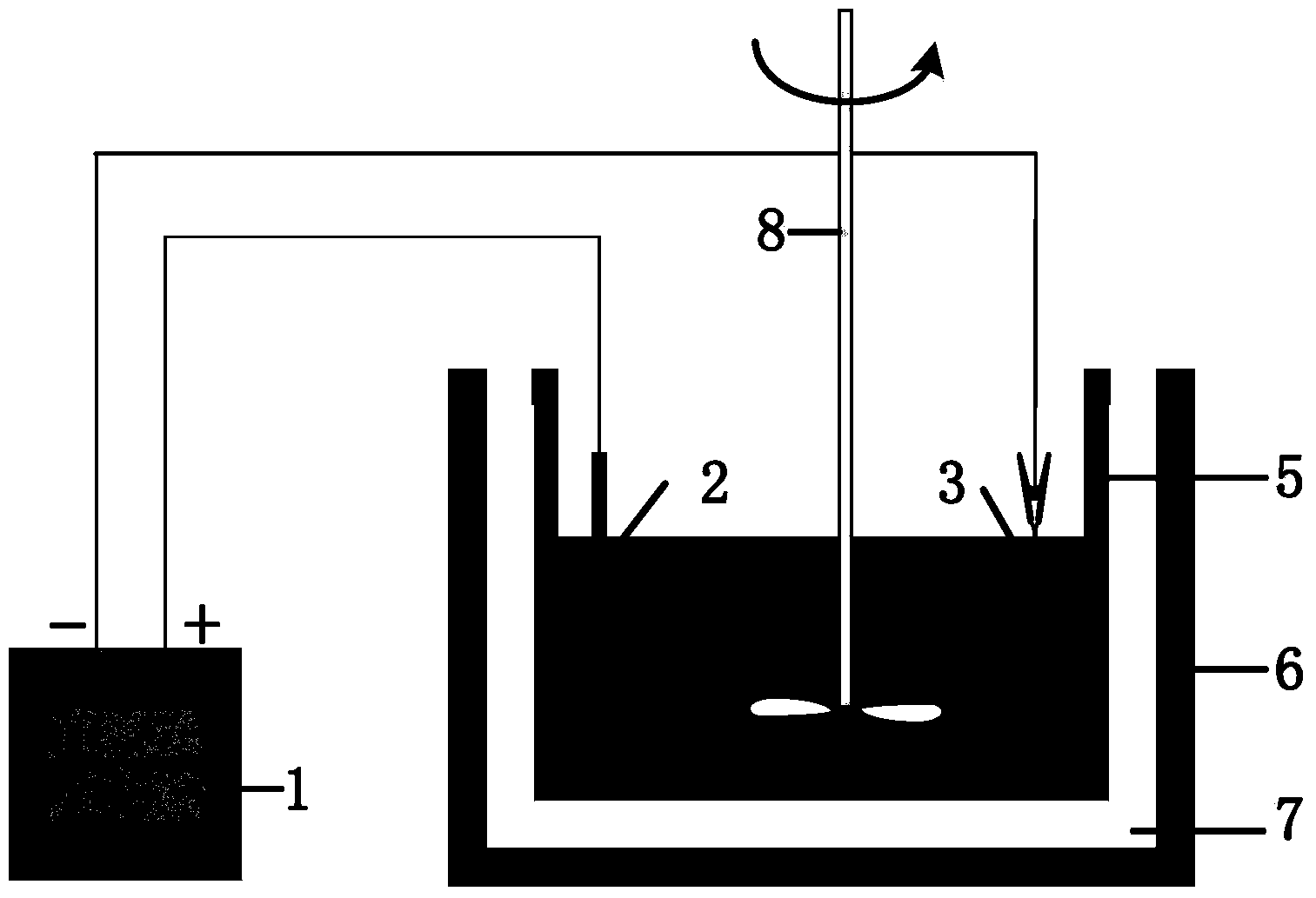

Method used

Image

Examples

Embodiment 1

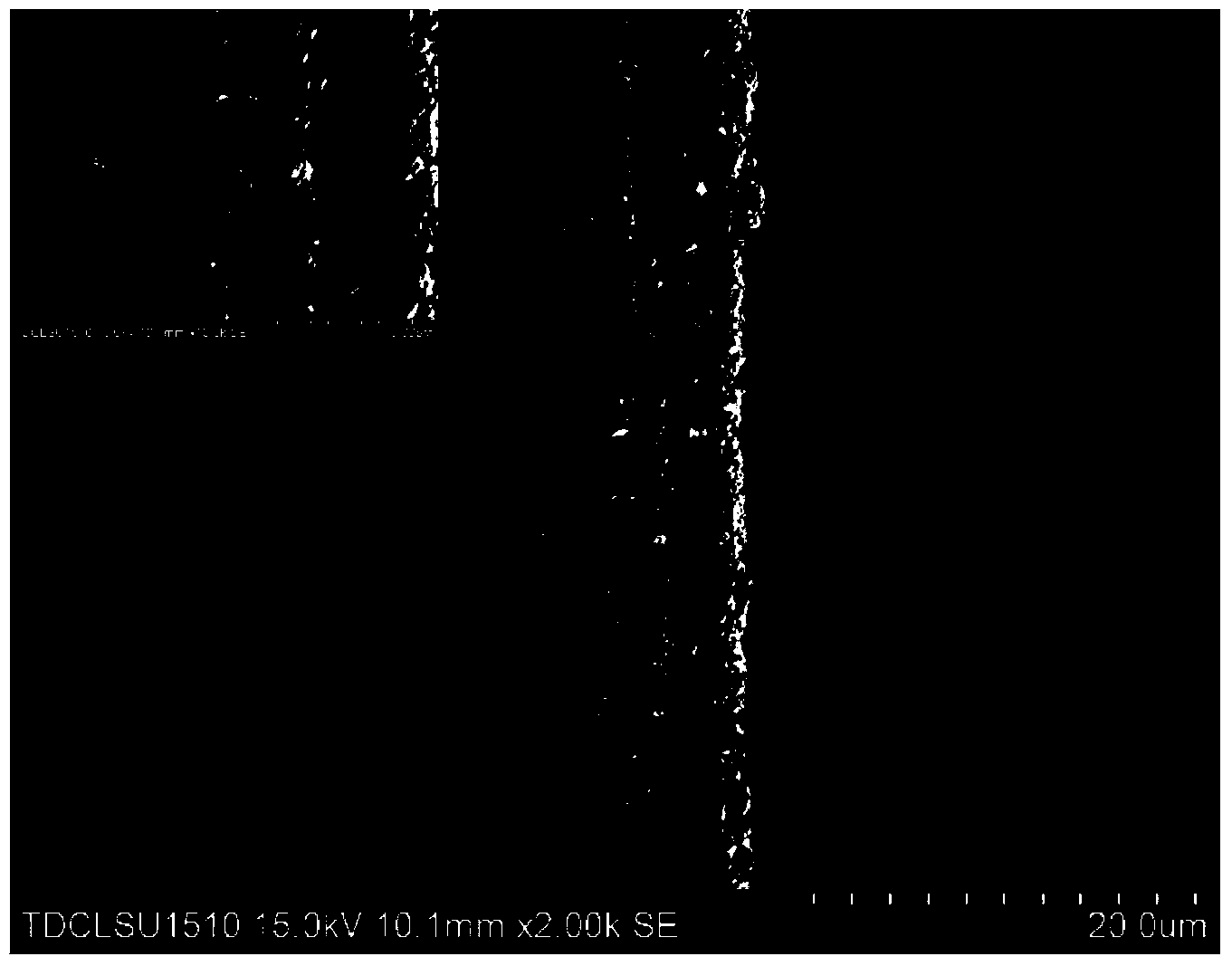

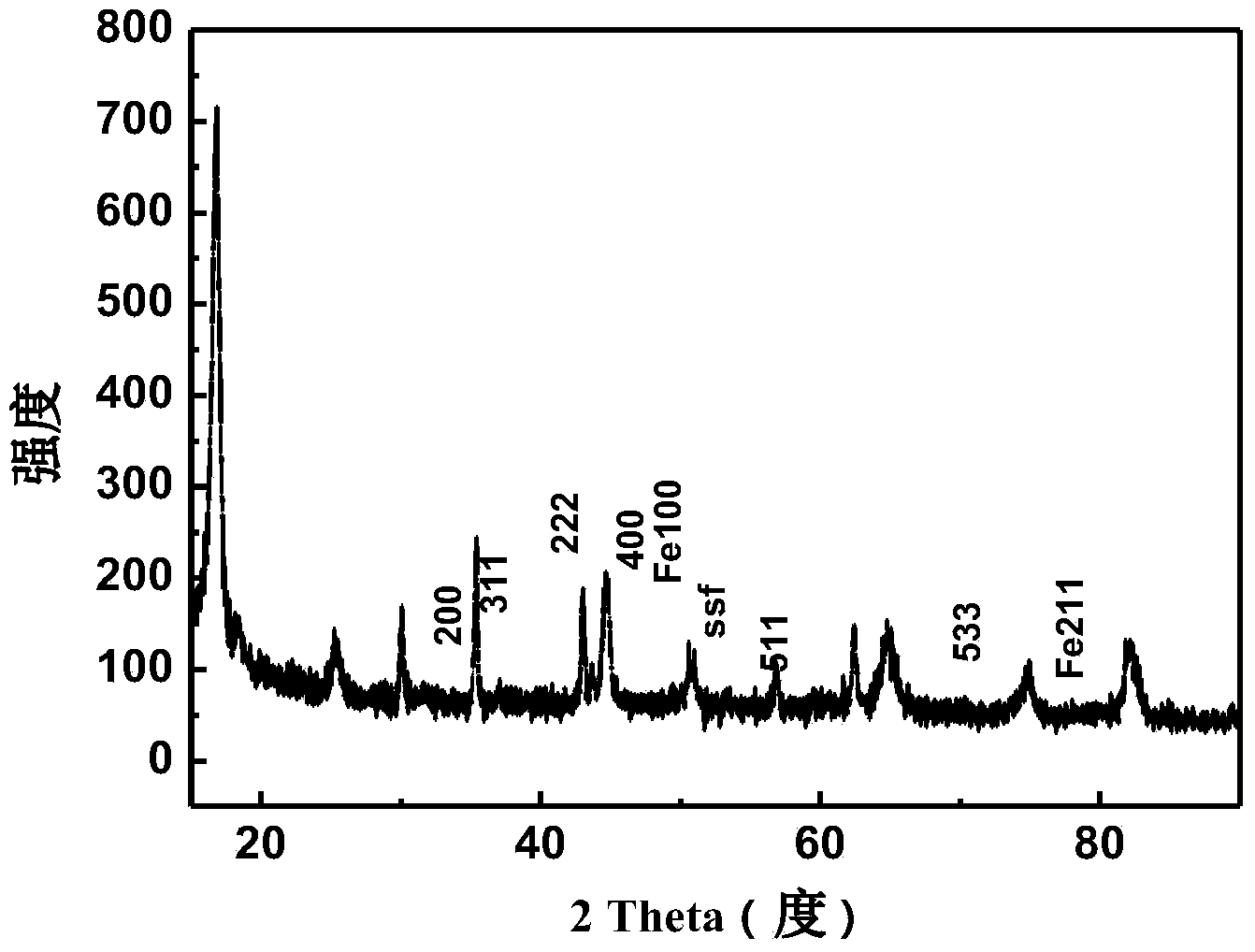

[0027] Embodiment 1: the preparation method of ferroferromagnetic layer electroplated on the surface of stainless steel fiber, comprising:

[0028] 1. Pretreatment of stainless steel fiber

[0029] Cut the 4K (a bundle of fibers is 4000 stainless steel fiber monofilaments) stainless steel fiber bundles with a monofilament diameter of 11 μm into a length of 5 cm, and place them in absolute ethanol at room temperature for ultrasound (ultrasonic instrument produced by Kunshan Hechuang Ultrasonic Instrument Co., Ltd. , the model is Kh5200E) cleaning 30min, rinse with deionized water 4 times after ultrasonic cleaning; then put the rinsed fiber in room temperature H 2 SO 4 (80mL / L) solution for ultrasonication for 5min, and finally rinsed with deionized water for 4 times, dried naturally and placed to be plated.

[0030] 2. Preparation of electroplating solution (ferric oxide solution)

[0031] First configure 0.09mol ferric chloride solution A, heat to dissolve, add 0.1mol triet...

Embodiment 2

[0039] Embodiment 2: the preparation method of electroplating ferroferromagnetic layer on the surface of stainless steel fiber, comprising:

[0040] 1. Pretreatment of stainless steel fiber

[0041] Cut 4K stainless steel fiber bundles with a monofilament diameter of 11 μm (a bundle of 4000 stainless steel fiber monofilaments) into a length of 5 cm, and place them in absolute ethanol at room temperature for ultrasound (ultrasonic instrument produced by Kunshan Hechuang Ultrasonic Instrument Co., Ltd. , model Kh5200E) for 30 minutes, rinsed with deionized water 4 times after ultrasonic cleaning; then placed the rinsed fiber in H2SO4 (80mL / L) solution at room temperature for 5 minutes, and finally rinsed with deionized water 4 times, After it dries naturally, it is left to be plated.

[0042] 2. Preparation of electroplating solution (ferric oxide solution)

[0043] First prepare 0.09 mol of ferric chloride solution A, heat to dissolve, add 0.1 mol of triethanolamine into prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com