Industrial production process fault monitoring method based on hierarchical non-Gaussian monitoring algorithm

A technology for industrial production and fault monitoring, applied in the direction of program control, comprehensive factory control, electrical program control, etc., can solve the problems of unclear distribution of process data, failure to detect and monitor fault status in real time, and achieve the goal of ensuring safety and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

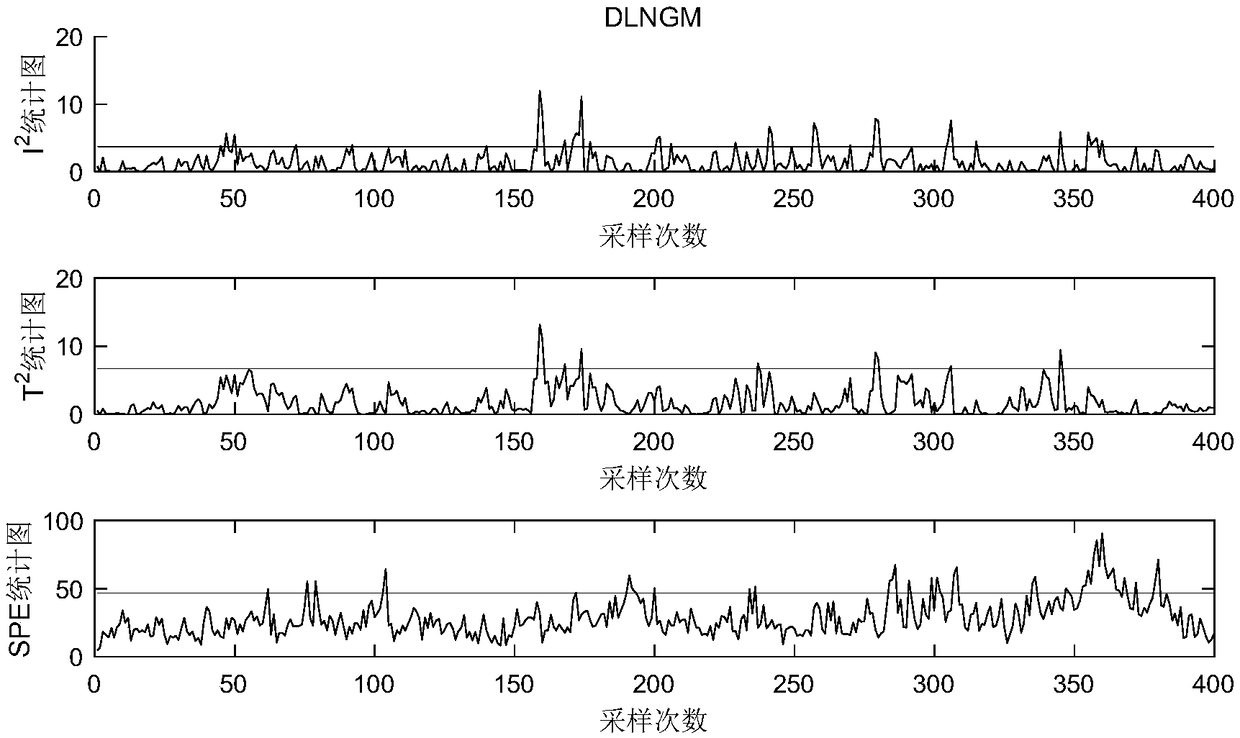

[0069] The method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific examples of implementation.

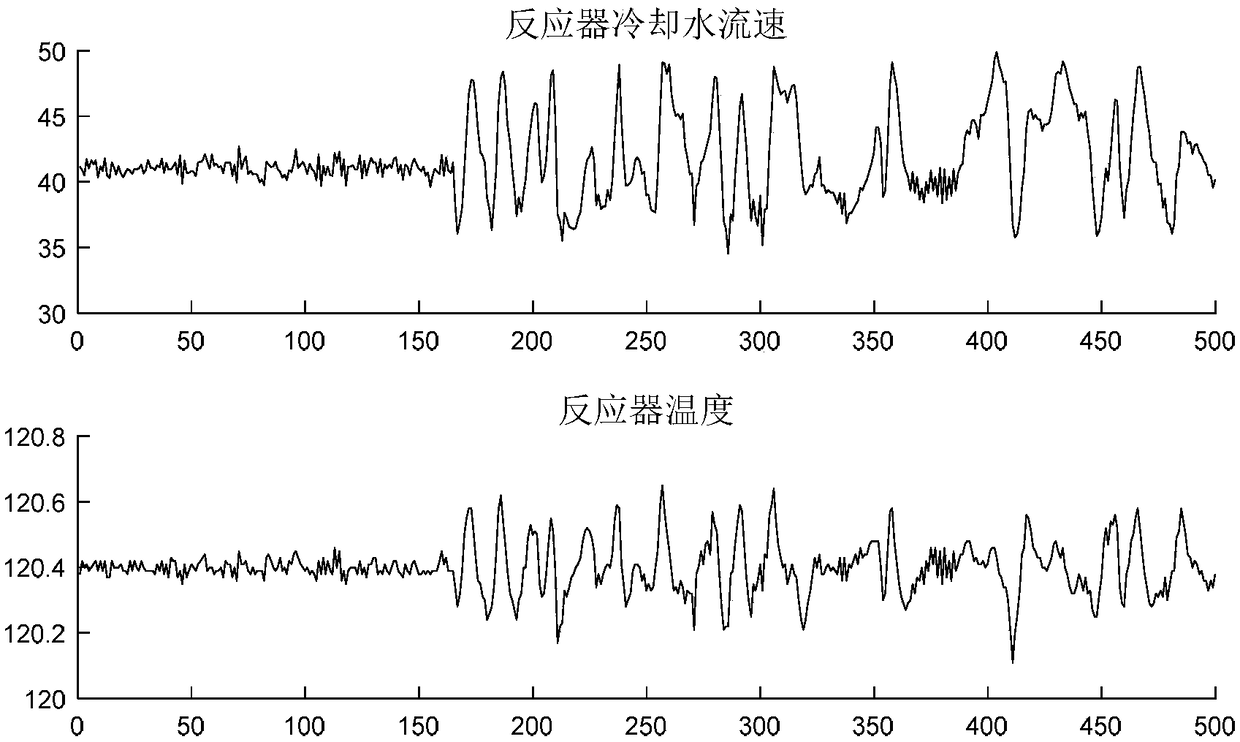

[0070] The specific implementation case adopted by the present invention is the Tennessee Eastman (TE) process, which includes five main units: reactor, condenser, compressor, separator and stripper.

[0071] The product stream from the reactor is cooled by a condenser before being sent to a vapor / liquid separator. The vapor from the separator is recycled to the reactor through the compressor. To prevent the build-up of inert components and reaction by-products in the process, a portion of the recycle stream must be vented. The condensed fraction (stream 10) from the separator is pumped to the stripper. Stream 4 is used to strip the remaining reactants in stream 10 which are combined via stream 5 with a recycle stream for the next reaction.

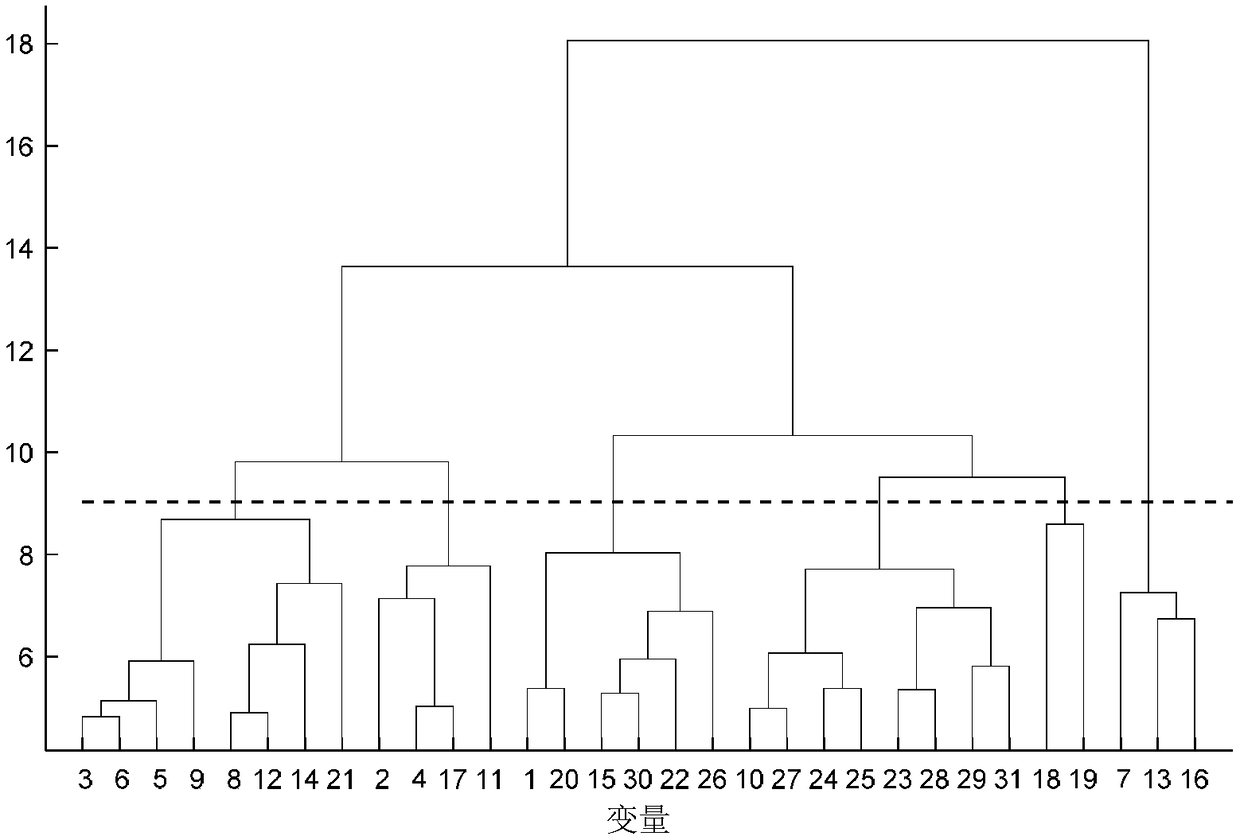

[0072] The Tennessee Eastman (TE) process has a total of 41 measured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com