Pulley device for reducing friction of paying-off construction

A technology of friction force and pulley, which is applied in the direction of overhead line/cable equipment, etc., can solve the problems of wire and lead rope sheath damage loss, increase the damage of traction broken rope pulley, increase the safety risk of power transmission construction, etc., and achieve the reduction of construction safety risk, Increased passability and protection, reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

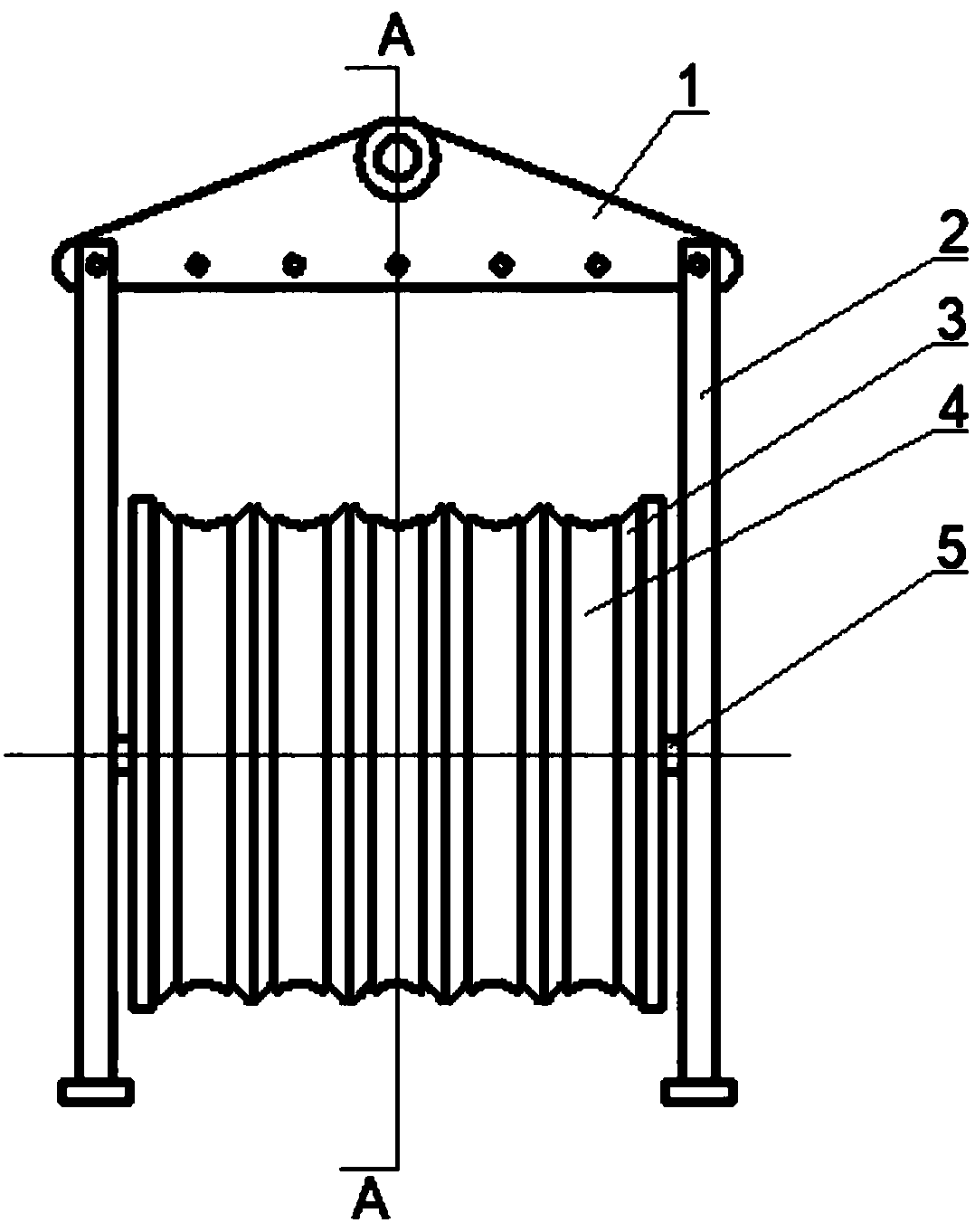

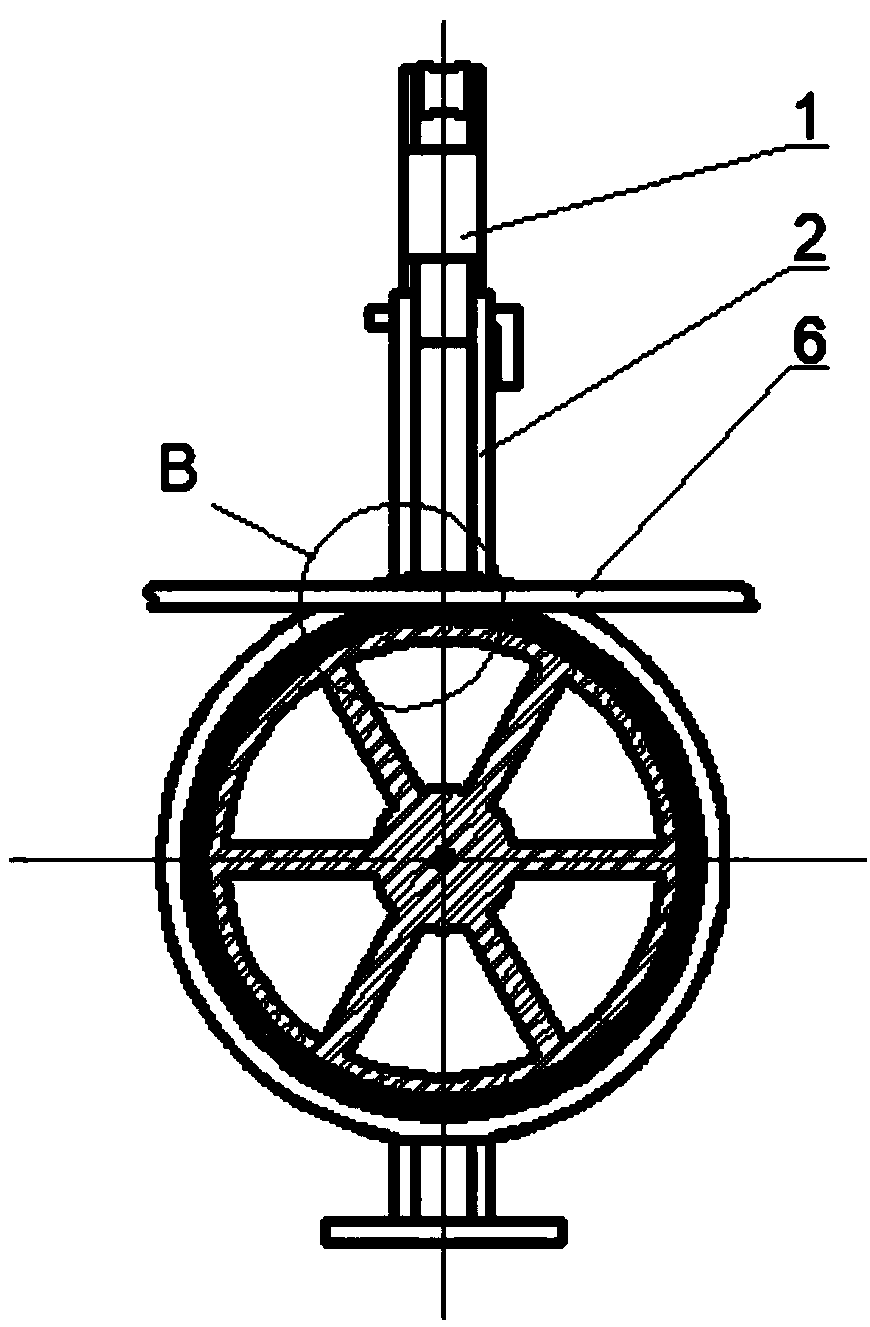

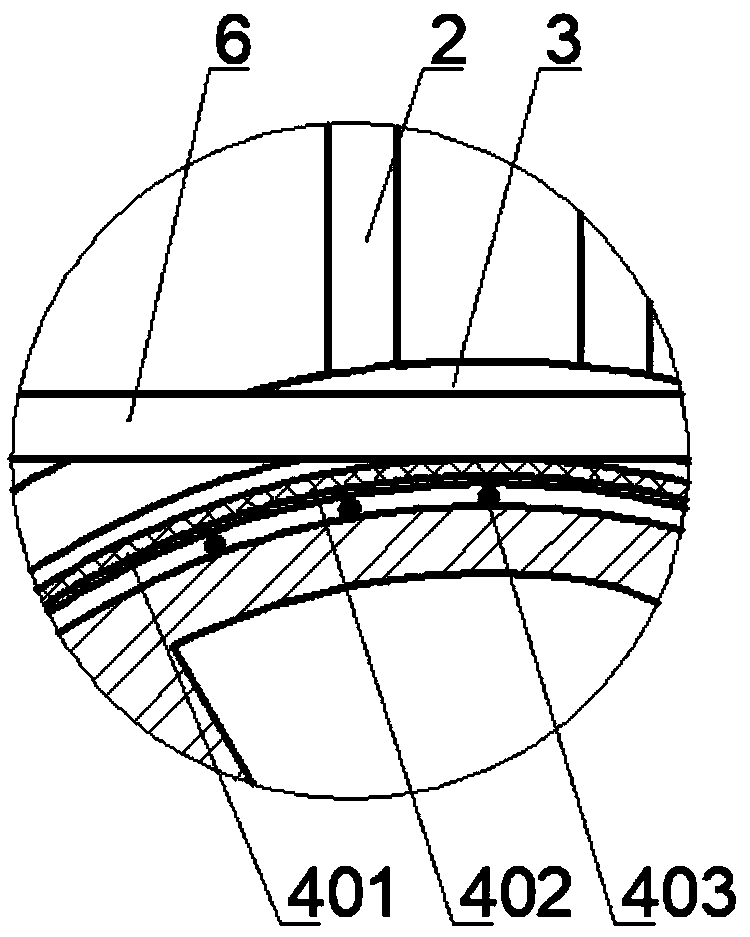

[0018] A pulley device for reducing friction in setting out construction, including a hoisting plate 1, a hanger 2, a main shaft 5, a pulley 3 and a ferrule 4, hangers 2 are symmetrically installed on both sides of the lower end of the hoisting plate, and in the middle of the hangers on both sides A main shaft 5 is installed, and a plurality of pulleys 3 are mounted coaxially and side by side on the main shaft. An annular groove is formed on the outer circumference of the pulley, and a set of rings 4 is set in the annular groove, and the ring is carried out in the groove of the pulley. Flexible rotation, the wire 6 or the traction rope passing through the pulley is erected on the ferrule, thereby prev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com