Extraction tank device for soy proteins

A technology of soybean protein and extraction tank, which is applied to the protein composition of vegetable seeds, protein food components, solid solvent extraction, etc., can solve the problems of unsatisfactory rotation, unsatisfactory, inconvenient internal filter residue cleaning, etc., to achieve easy installation and disassembly , wide range of use, good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

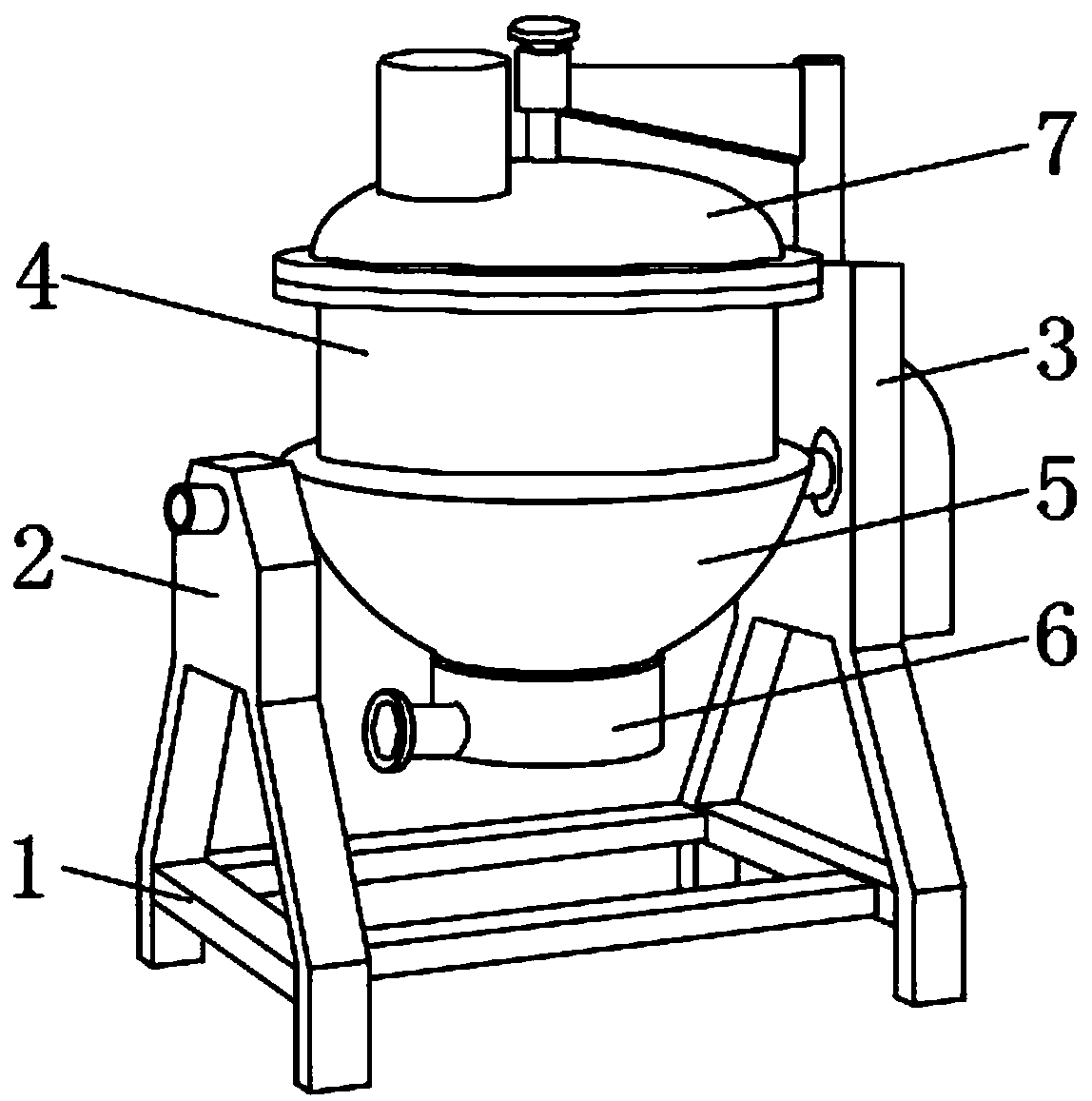

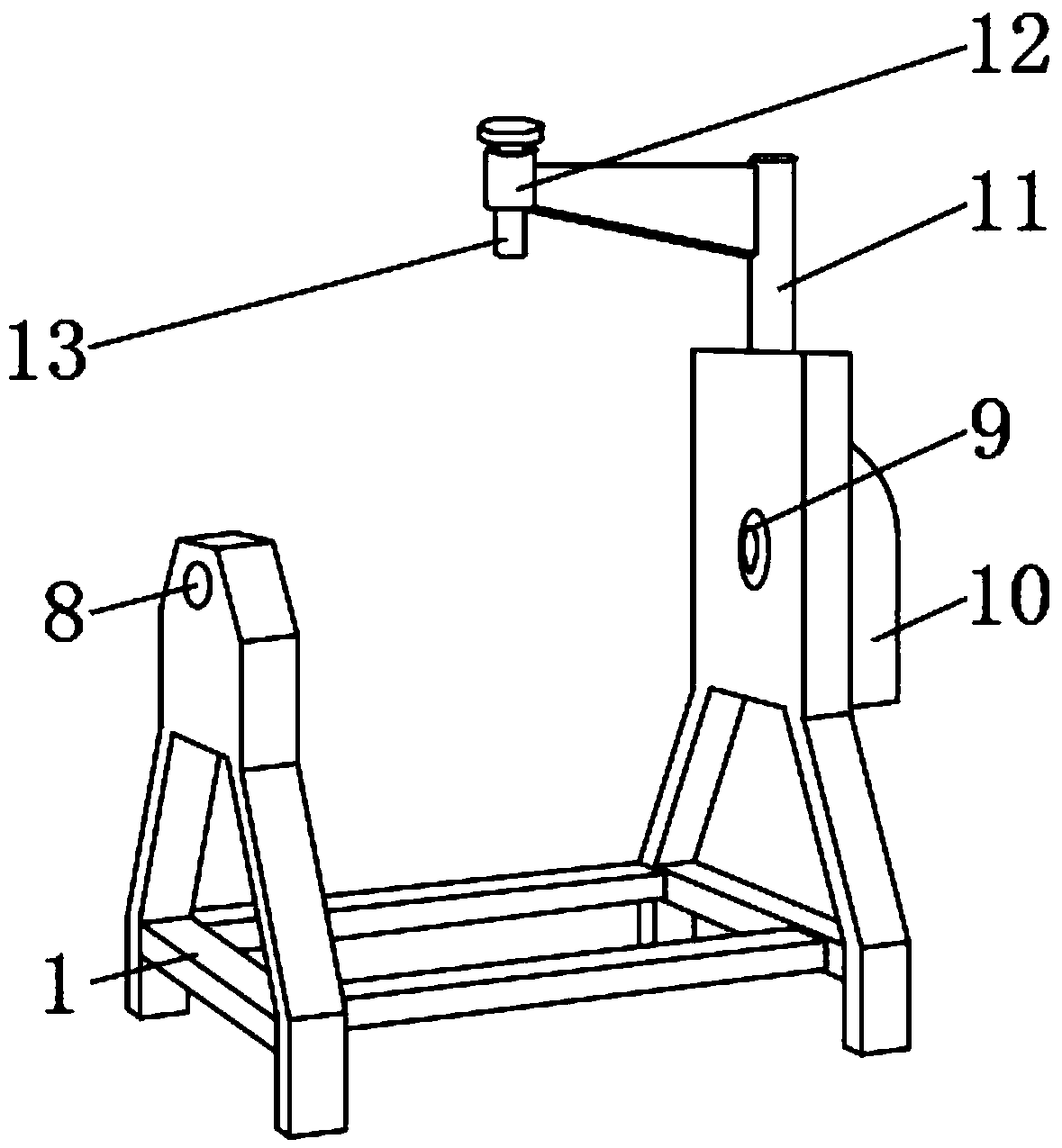

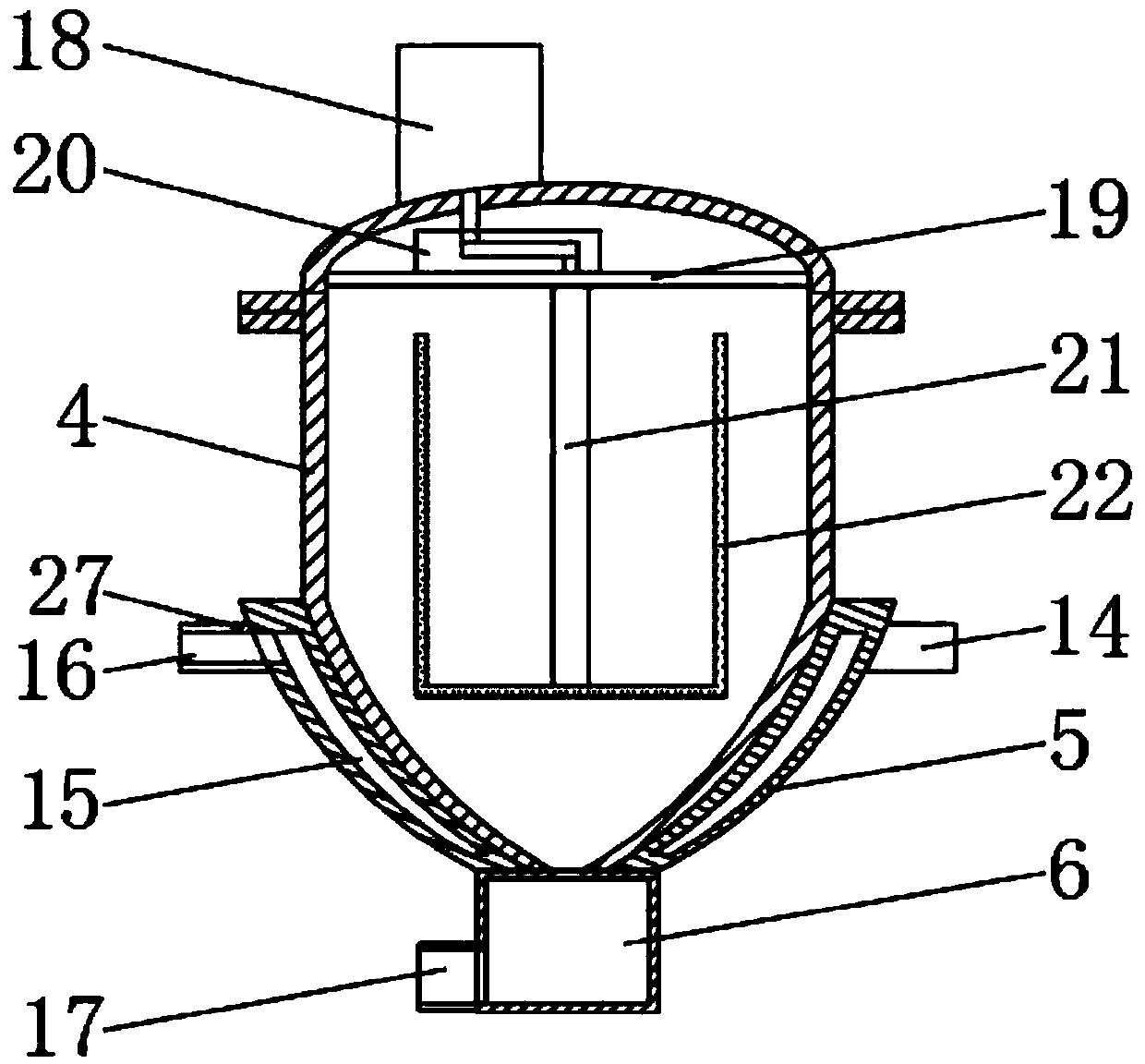

[0026] Such as Figure 1-5 As shown, a soy protein extraction tank device includes a support frame 1 and an extraction tank body 4. The extraction tank body 4 is located at the upper end of the support frame 1, and a support rod 2 is fixedly installed on the upper end side of the support frame 1. The supporting frame 1 is fixedly installed on the other side of the upper end of the No. 2 strut 3, the No. 1 strut 2 is provided with a No. 1 mounting hole 8 inside, and the No. 2 strut 3 is provided with a No. 2 mounting hole 9 inside. A mounting sleeve 5 is fixedly installed on the outer circumferential surface of the bottom end of the mounting sleeve 5. A transmission rod 14 is fixedly installed on the upper side of the mounting sleeve 5, and the transmission rod 14 is located inside the second mounting hole 9, and the upper end of the mounting sleeve 5 is fixed on the other side A driven rod 27 is installed, and the driven rod 27 is located inside the first mounting hole 8.

[002...

Embodiment 2

[0030] Such as Figure 1-5 As shown, a soy protein extraction tank device includes a support frame 1 and an extraction tank body 4. The extraction tank body 4 is located at the upper end of the support frame 1, and a support rod 2 is fixedly installed on the upper end side of the support frame 1. The supporting frame 1 is fixedly installed on the other side of the upper end of the No. 2 strut 3, the No. 1 strut 2 is provided with a No. 1 mounting hole 8 inside, and the No. 2 strut 3 is provided with a No. 2 mounting hole 9 inside. A mounting sleeve 5 is fixedly installed on the outer circumferential surface of the bottom end of the mounting sleeve 5. A transmission rod 14 is fixedly installed on the upper side of the mounting sleeve 5, and the transmission rod 14 is located inside the second mounting hole 9, and the upper end of the mounting sleeve 5 is fixed on the other side A driven rod 27 is installed, and the driven rod 27 is located inside the first mounting hole 8.

[003...

Embodiment 3

[0036] Such as Figure 1-5 As shown, a soy protein extraction tank device includes a support frame 1 and an extraction tank body 4. The extraction tank body 4 is located at the upper end of the support frame 1, and a support rod 2 is fixedly installed on the upper end side of the support frame 1. The supporting frame 1 is fixedly installed on the other side of the upper end of the No. 2 strut 3, the No. 1 strut 2 is provided with a No. 1 mounting hole 8 inside, and the No. 2 strut 3 is provided with a No. 2 mounting hole 9 inside. A mounting sleeve 5 is fixedly installed on the outer circumferential surface of the bottom end of the mounting sleeve 5. A transmission rod 14 is fixedly installed on the upper side of the mounting sleeve 5, and the transmission rod 14 is located inside the second mounting hole 9, and the upper end of the mounting sleeve 5 is fixed on the other side A driven rod 27 is installed, and the driven rod 27 is located inside the first mounting hole 8.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com