Double-face glass plate cleaning device for glass instrument

A technology for glass instruments and cleaning devices, applied in chemical instruments and methods, cleaning methods using tools, cleaning methods using liquids, etc., can solve the problems of time-consuming, labor-intensive, low cleaning efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

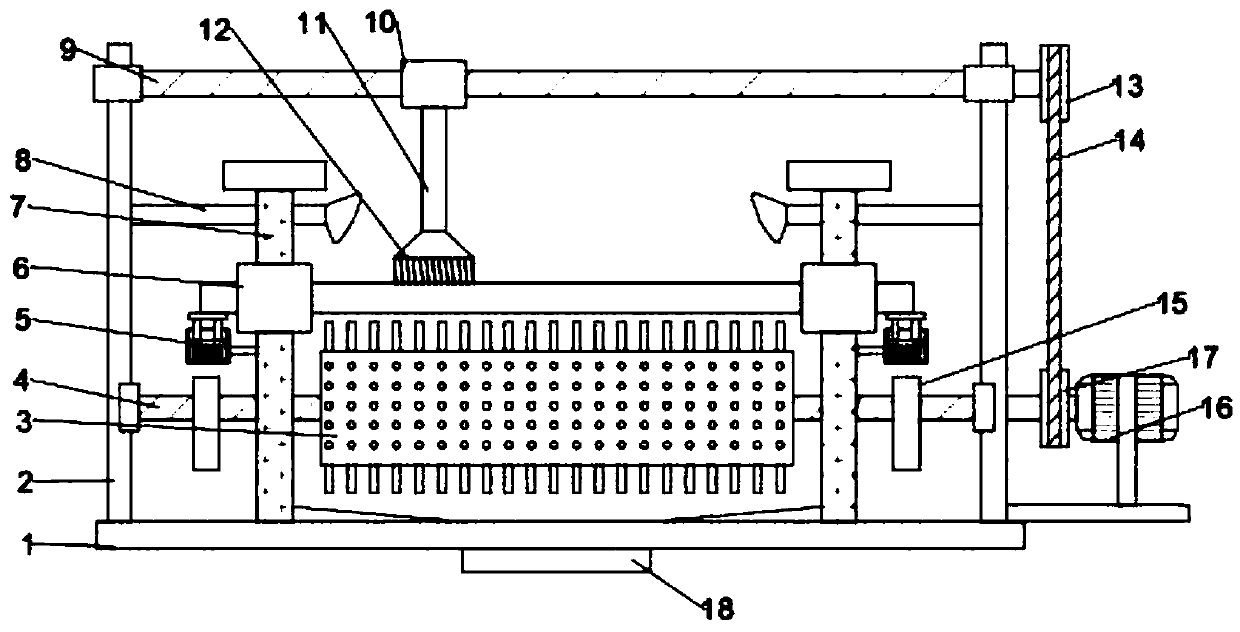

[0020] see Figure 1~2 , in an embodiment of the present invention, a double-sided cleaning device for glass plates for glass instruments, including a base 1, a vertical plate 2, a cleaning roller 3, a first slider 6 and a first guide rod 7, the upper surface of the base 1 is symmetrical Two vertical boards 2 are set, and the vertical boards 2 and the base 1 are fixedly connected by bolts, and the first guide rods 7 are arranged on the side of the vertical boards 2 close to each other. There are two first guide rods 7, and about the base 1 The vertical central axis is arranged symmetrically, the first slider 6 is movably arranged on the first guide rod 7, and the glass plate is clamped between the first sliders 6;

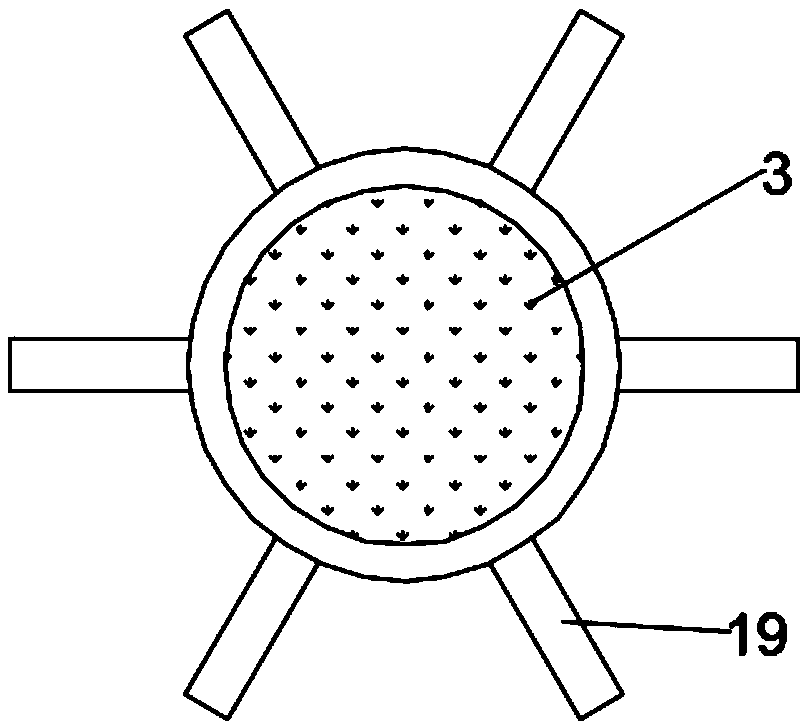

[0021] A cleaning roller 3 is arranged below the first slide block 6, and a plurality of cleaning belts 19 are uniformly distributed on the outer surface of the cleaning roller 3, and a rotating shaft 4 is arranged on the horizontal central axis of the cleaning rol...

Embodiment 2

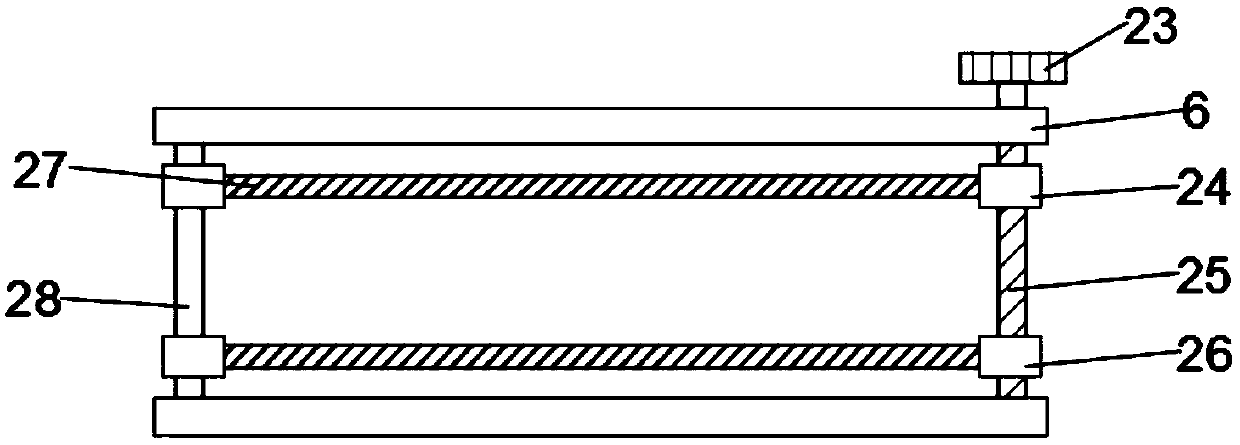

[0027] see figure 1 , 3 , 4. In the embodiment of the present invention, a second guide rod 28 and a threaded rod 25 are arranged symmetrically on the left and right sides of the first slider 6, and a splint 27 is arranged between the threaded rod 25 and the second guide rod 28, so that There are two splints 27, and the third slide block 24 is fixedly welded on both sides of the splint 27 described above, and the inner wall of the third slide block 24 is provided with internal threads, and the third slide block 24 on the right side is connected with the thread Rod 25 threaded connection;

[0028] The fourth slider 26 is fixedly welded on both sides of the splint 27 described below, the fourth slider 26 described on the left is fixedly welded to the second guide rod 28, and the fourth slider 26 described on the right is slidably connected to the Threaded rod 25, the upper end of the threaded rod 25 runs through the upper wall of the first slider 6, and the welding gear 23 is ...

Embodiment 3

[0031] A glass instrument cleaning device, comprising the double-sided cleaning device for glass plates used in glass instruments as described in Embodiment 2.

[0032] The working principle of the present invention is: when the glass plate needs to be cleaned, turning the gear 23 can make the gear 23 drive the threaded rod 25 to rotate, thereby realizing the vertical movement of the third slider 24 and the splint 27. straight sliding, so as to realize the fixing of the glass plate between the clamping plates 27, and the working motor 16 starts to drive the rotating shaft 4 to rotate, so that the rotating shaft 4 can drive the cleaning roller 3 and the cleaning belt 19 to rotate, thereby The lower surface of the glass plate is fully cleaned, the rotation of the second wheel 17 drives the rotation of the shaft 4, and the rotation of the shaft 4 drives the cam 15, thereby realizing the intermittent cleaning of the buffer box 5. Sexual extrusion, so that the buffer box 5 drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com