Steel ladle slide gate mechanism and steelmaking equipment

A technology for sliding nozzles and ladles, applied in casting equipment, metal processing equipment, casting melt containers, etc., can solve problems such as inaccurate regulation of sliding nozzles, unstable surface pressure between plates, molten steel splashing or unstable flow control, etc. , to achieve stable surface pressure between plates, improve control accuracy, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

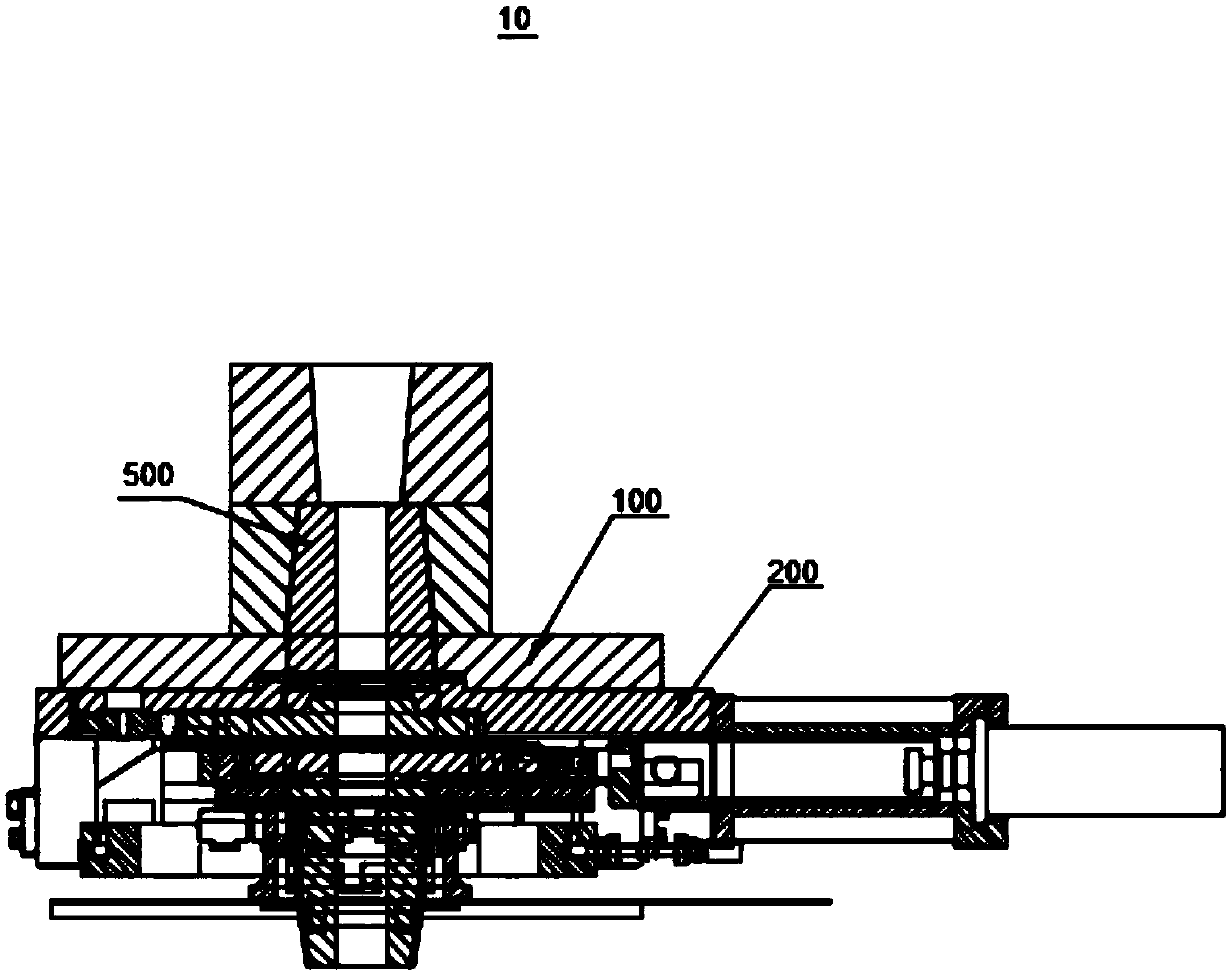

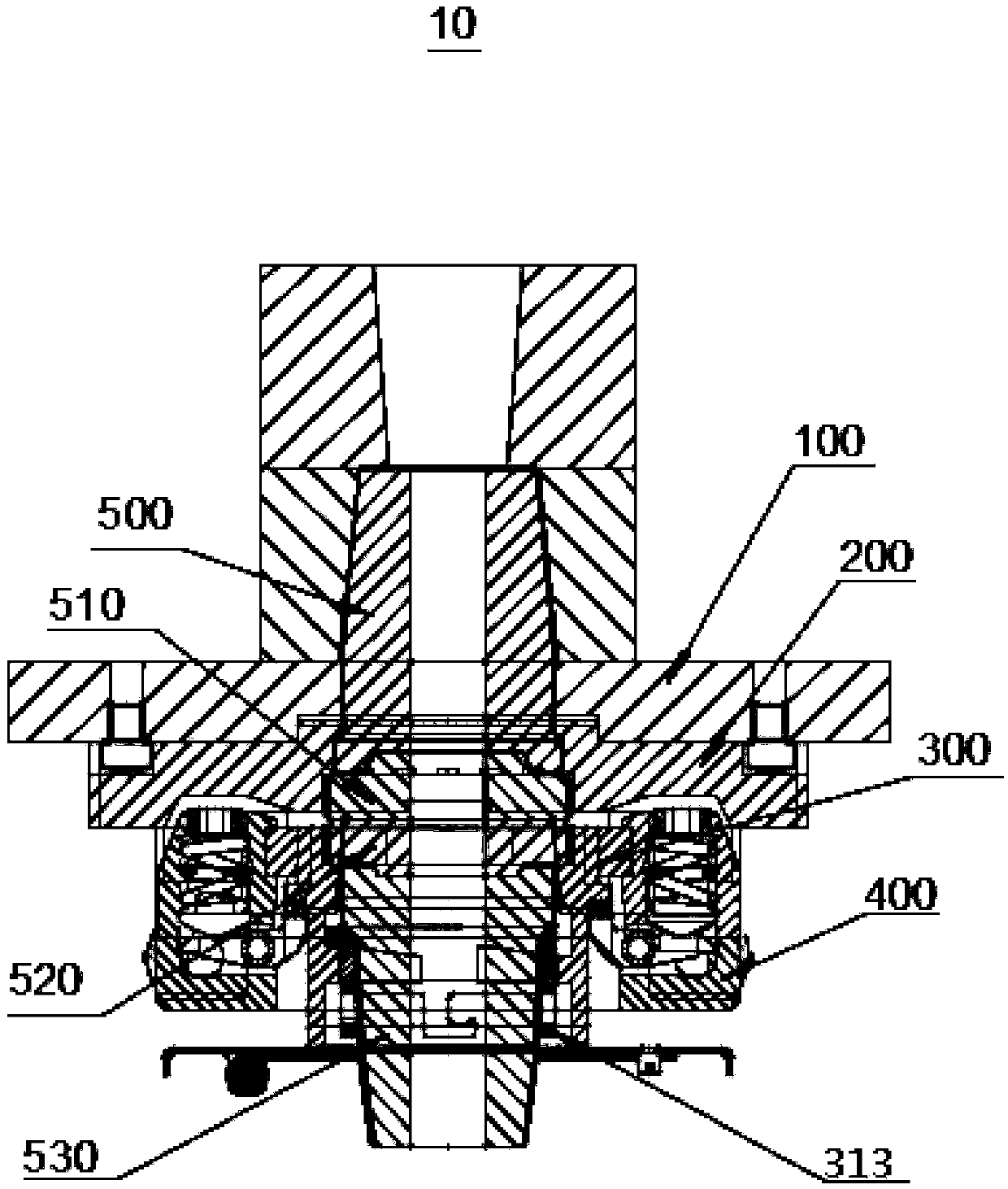

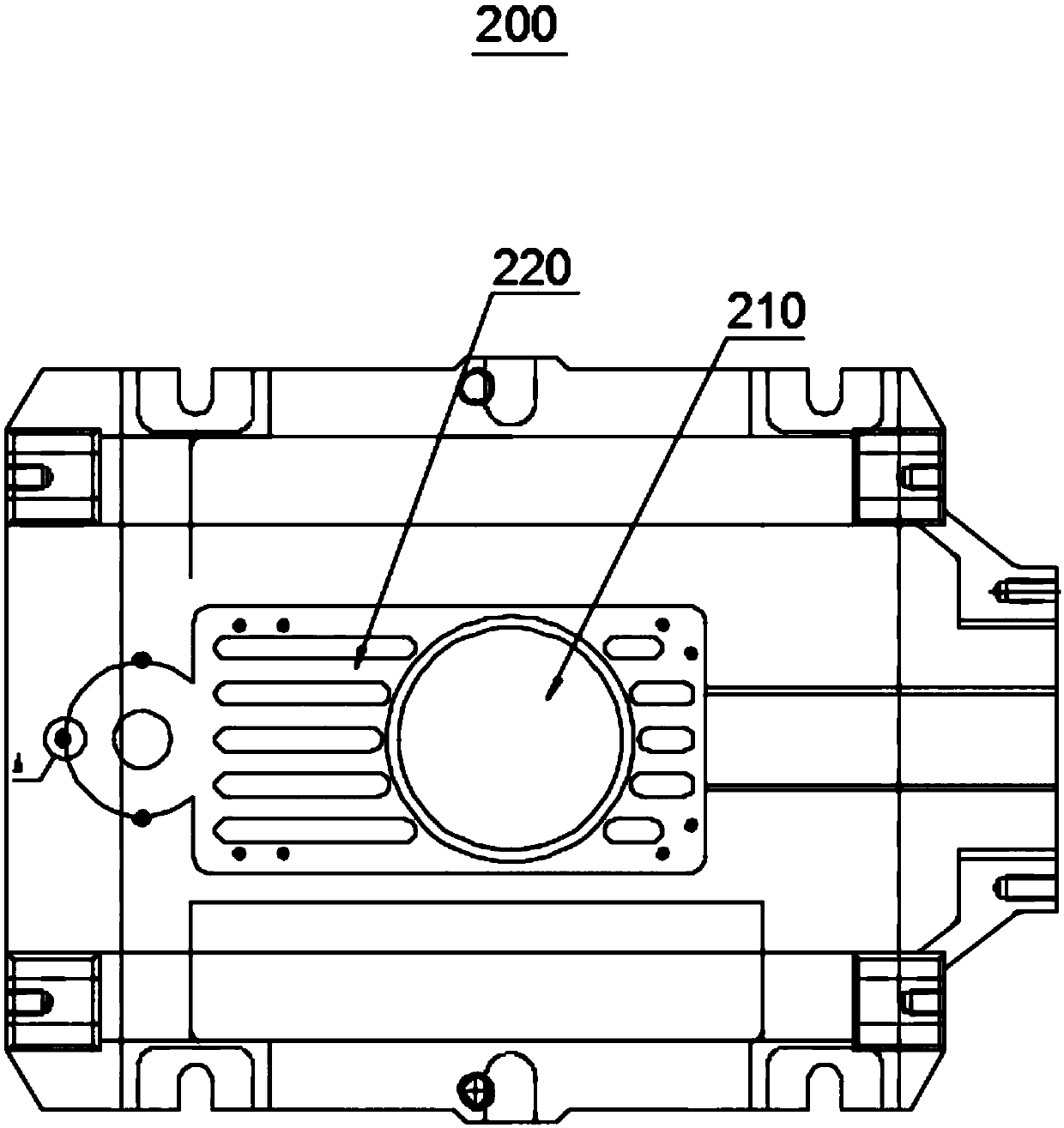

[0041] Please refer to the attached Figure 1~2 , the present embodiment provides a ladle sliding nozzle mechanism 10, which includes a mounting plate part 100 for connecting the ladle sliding nozzle mechanism 10 with the ladle, a base part 200, a sliding car part 300 and a surface pressure spring 413 frame part Pack.

[0042] The ladle sliding nozzle mechanism 10 can improve the accuracy of flow control of molten steel, avoid or reduce the situation that the sliding nozzle device fails and needs to be shut down for maintenance, can effectively improve work efficiency, and reduce and save production costs.

[0043] Specifically, the installation board part 100 is provided with: the upper nozzle 500 for installing the upper nozzle 500 is installed through a positioning hole. Mounting plate part dresses 100 and is used for being installed on the ladle bottom, is used for placing seat brick, upper nozzle 500 and connects fixed base part dresses 200, and then makes ladle sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com