High-voltage power temperature measuring system

A technology of high-voltage electric power and infrared temperature measurement, which is applied in the field of power systems, can solve problems such as electrical equipment damage, fire, and aggravated contact surface oxidation, and achieve the effects of good reliability, reduced faults, and perfect functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to further illustrate the present invention, the present invention will be further described in detail below in conjunction with preferred embodiments.

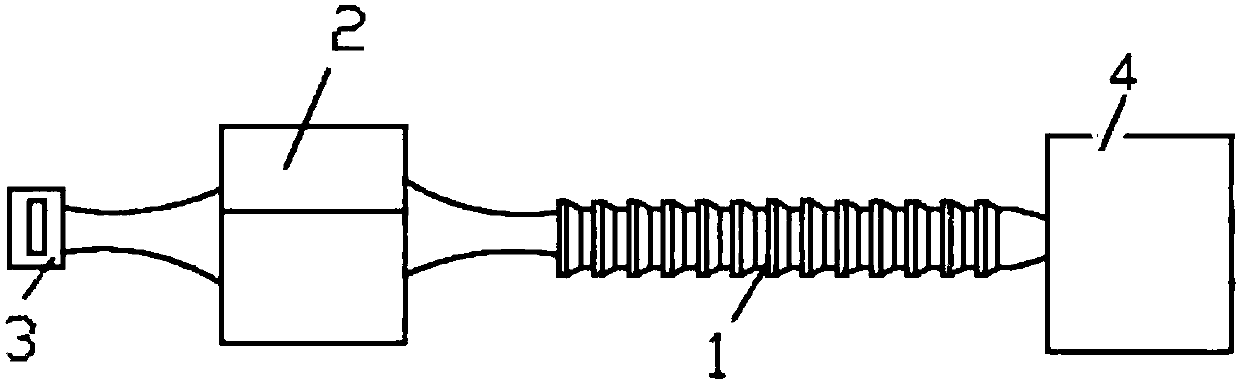

[0009] Such as figure 1 As shown, it includes an infrared temperature measurement probe 4 and a non-contact infrared temperature measurement sensor 1; the infrared temperature measurement probe 4 collects data and is connected to a non-contact infrared temperature measurement sensor 1, and one end of the non-contact infrared temperature measurement sensor 1 is connected to a The wireless temperature measurement transmitter module 2, the non-contact infrared temperature measurement sensor 1 transmits the monitored temperature signal through the wireless temperature measurement transmitter module 2, and the non-contact infrared temperature measurement sensor 1 and the wireless temperature measurement transmitter module 2 are connected The bands 3 are connected together to realize the installation of the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com