Rotary recliner for vehicle seat

A vehicle seat and rotary technology, which is applied to vehicle seats, vehicle parts, special positions of vehicles, etc., can solve difficult problems such as clutch discs, and achieve the effects of simple structure, slack prevention, and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

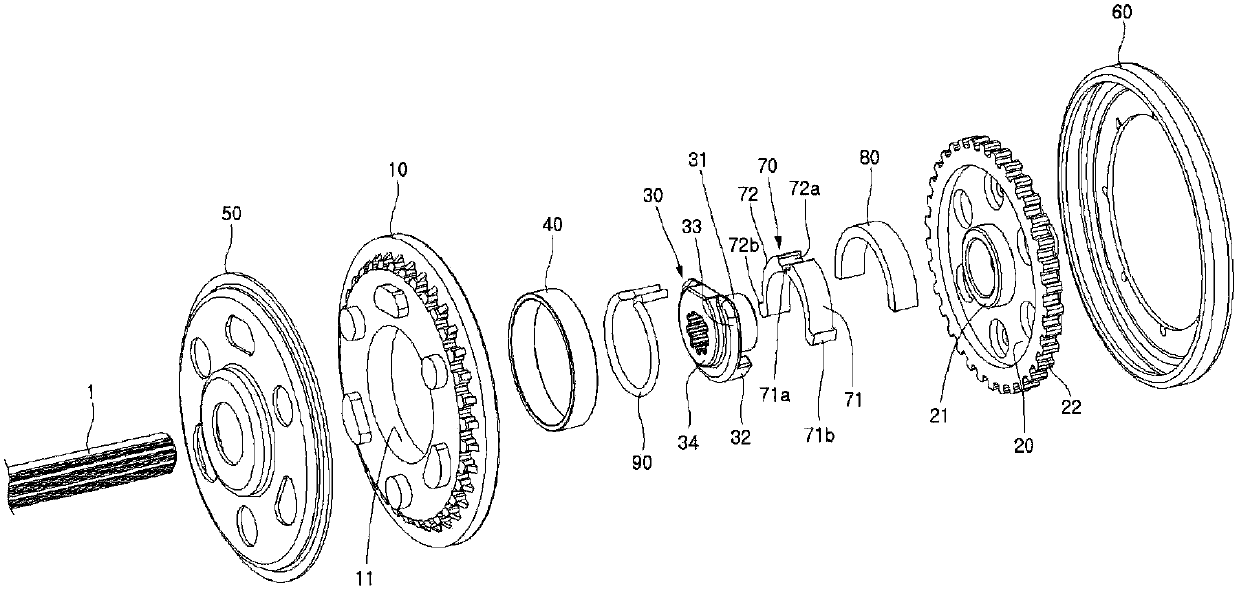

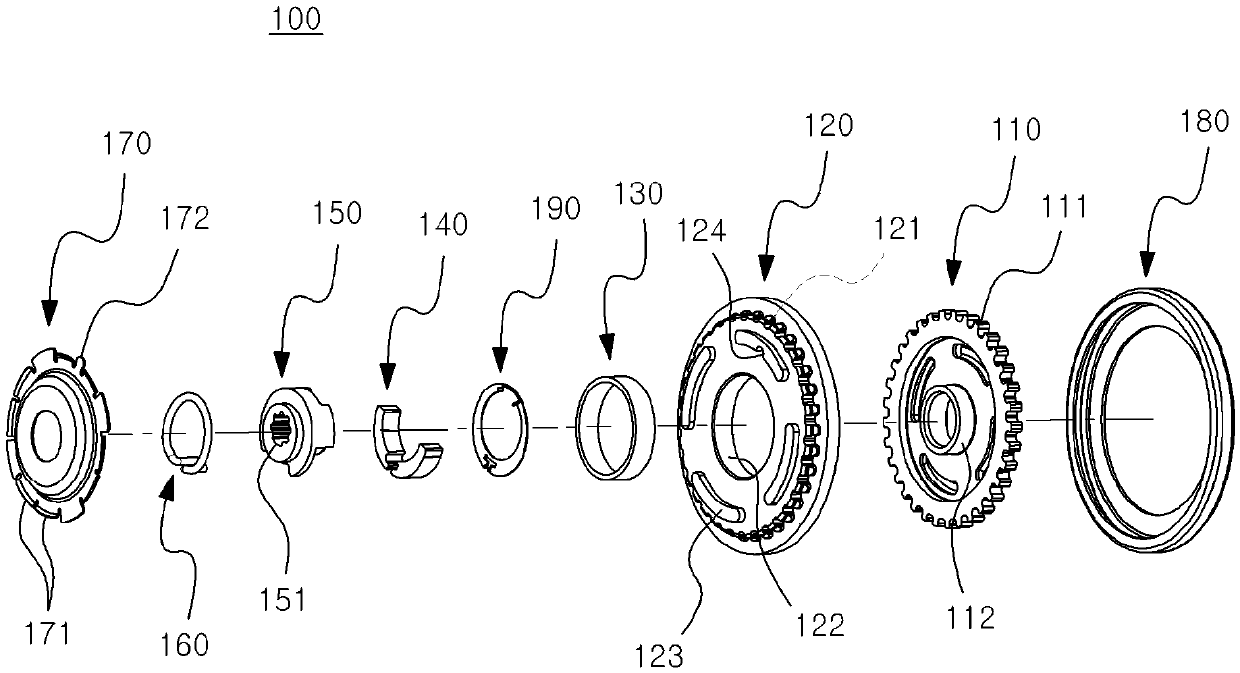

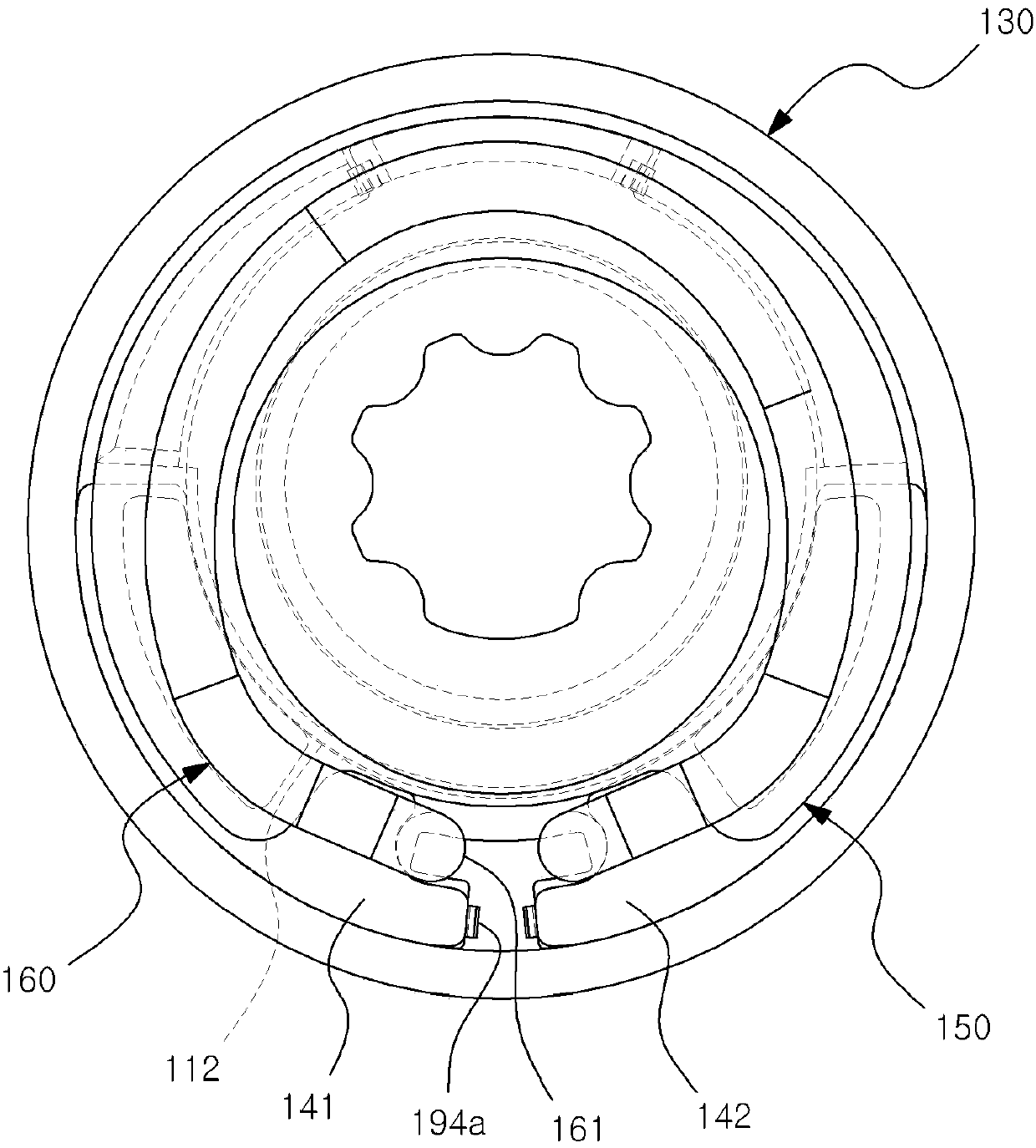

[0030] Such as figure 2 As shown, the structural configuration of the vehicle seat rotary recliner 100 according to the first embodiment of the present invention is as follows, a bearing 130, a pair of wedges 140, a cam 150, and a spring are accommodated between the large gear plate 110 and the ring gear plate 120. 160 and leaf spring 190 are covered and supported by cover plate 170 and outline cover 180 in their state.

[0031] The large gear plate 110 forms outer teeth (outer teeth, 111 ) on the outer peripheral surface and protrudes from the center to form a hub portion (bush, 112 ).

[0032] The ring gear plate 120 has inner teeth (121) for meshing with the outer teeth 111 on the outer peripheral surface, and a circular bearing support hole 122 is formed on the inner side, and the center of the circular bearing support hole 122 is deviated from the hub. Section 112 Center.

[0033] The bearing 130 is sandwiched into the bearing support hole 122 of the ring gear plate 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com