Gluing head control mechanism of full automatic gluing flanging machine

A technology of a control mechanism and a folding machine, which is applied to the field of gluing mechanism of leather products, can solve the problems of overflowing glue, unstable glue control of automatic folding machine, and inability to lift the glue head, so as to avoid trimming and removing glue. work, avoid unstable operation, and overcome the effect of work fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

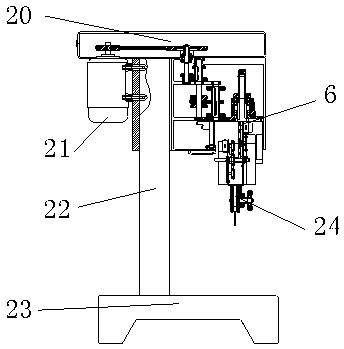

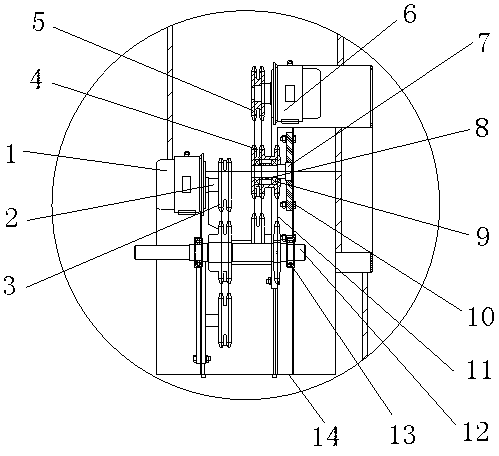

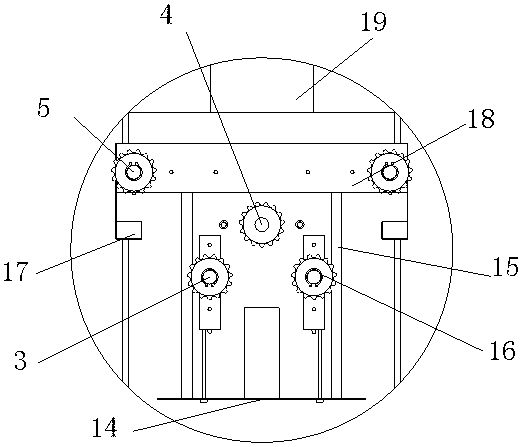

[0018] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

[0019] see Figure 1-4 , the present invention provides a technical solution: a rubber head control mechanism of a fully automatic gluing and folding machine, including a first motor 1, the first motor 1 is a stepping motor that converts electrical pulse signals into angular displacement or The electromechanical components of linear displacement, the input of the stepping motor is a pulse sequence, and the output is the corresponding incremental displacement or stepping motion. Under normal motion, it has a fixed number of steps per revolution and performs continuous stepping motion. , its rotation speed and the frequency of the input pulse maintain a strict corresponding relationship, and it is not affected by voltage fluctuations and load changes. Since the stepping motor can directly accept digital control, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com