A kind of ultra-high elastic photocuring temporary resin composition, its preparation method and application

A resin composition and light-curing technology, applied in the field of materials, can solve the problems of high price, urgent demand for elastic materials, cumbersome operation, etc., achieve high elastic modulus, fill the gap in the industry, and be simple and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

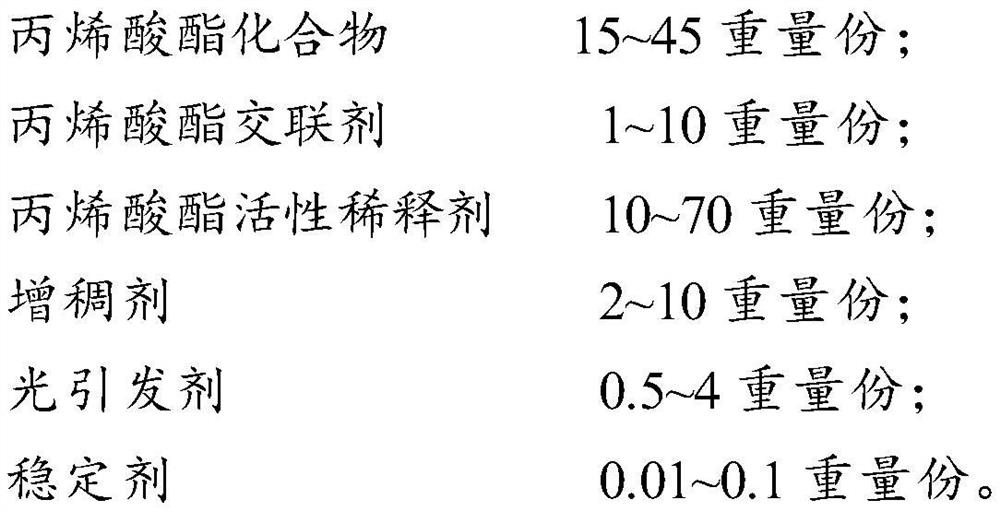

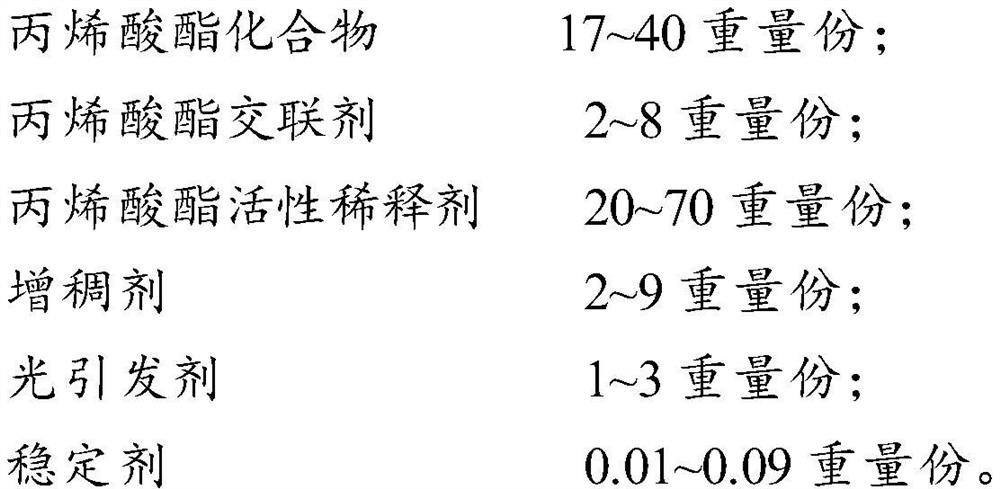

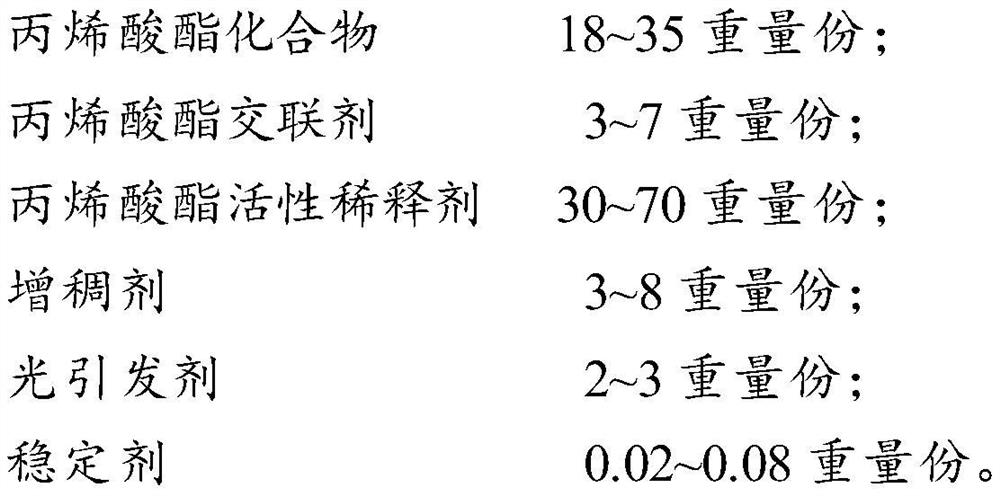

[0046] The present invention provides a method for preparing the ultra-high elastic light-cured temporary resin composition described in any one of the above technical solutions, comprising:

[0047] It is obtained by mixing an acrylate compound, an acrylate crosslinking agent, an acrylate reactive diluent, a thickener, a photoinitiator and a stabilizer.

[0048] The present invention has clearly described the specific components and proportions of the above-mentioned acrylate compound, acrylate crosslinking agent, acrylate reactive diluent, thickener, photoinitiator and stabilizer, and will not repeat them here.

[0049]The mixing in the present invention is preferably carried out in a mixing tank; the mixing temperature can be at room temperature; it is 20-35° C.; the mixing time is preferably 3-8 hours.

[0050] The present invention provides the application of the ultra-high elastic photocuring temporary resin composition described in any one of the above technical solutio...

Embodiment 1

[0058] The following components were stirred together to form a paste (mass %):

[0059]

[0060] Mix the above-mentioned components through a mixing tank at room temperature for 3 to 8 hours.

[0061] Apply the paste of the present invention to the parts that need to be covered, and it can be cured for 3 seconds by light to complete the covering and isolation. After the oral operation is completed, it can be directly torn off by hand.

[0062] Test results: flexural strength 70±5MPa, modulus 1.0±0.2GPa.

Embodiment 2

[0064] The following components were stirred together to form a paste (mass %):

[0065]

[0066] Mix the above-mentioned components through a mixing tank at room temperature for 3 to 8 hours.

[0067] Apply the paste of the present invention to the parts that need to be covered, and it can be cured for 3 seconds by light to complete the covering and isolation. After the oral operation is completed, it can be directly torn off by hand.

[0068] Test results: flexural strength 70±5MPa, modulus 1.0±0.2GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com