A highly stable modified silicone oil emulsion

A technology for modifying silicone and oil emulsions, which is applied in the treatment of dyed organosilicon compounds and fibrous fillers, etc. It can solve the problem of not mentioning the stability of modified silicone oil, the inability to conveniently adjust the length and quantity of side chains, and the inability to obtain modification Solve problems such as silicone oil emulsion, achieve good dispersion and improve oil dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

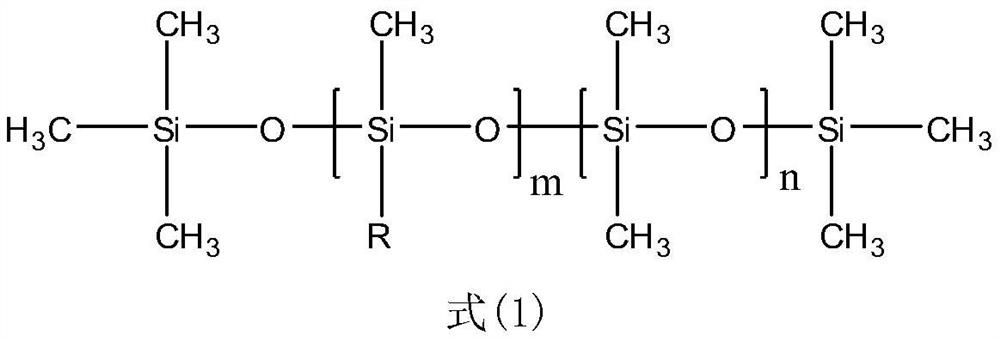

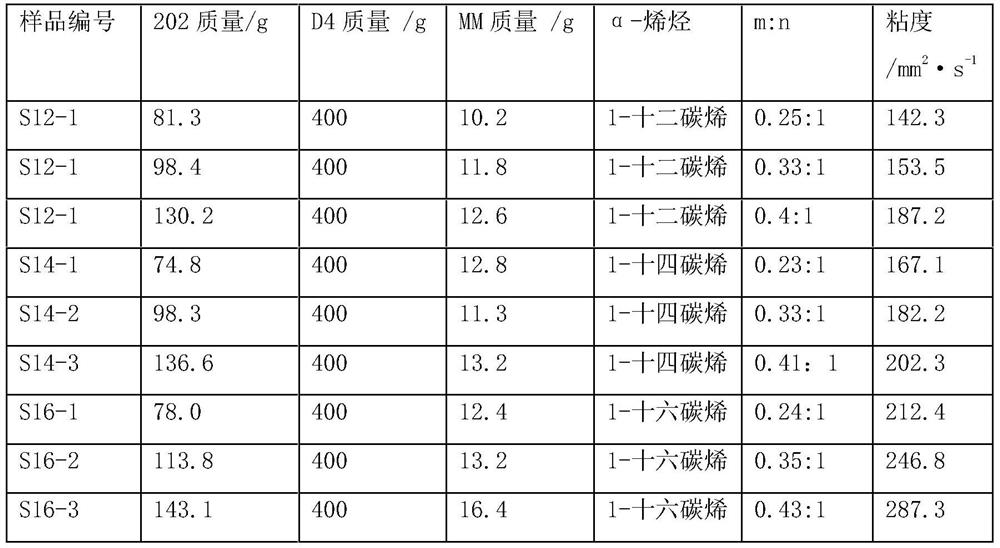

[0039] Preparation of long chain alkyl modified silicone oil:

[0040] The preparation method of the long-chain alkyl modified silicone oil can refer to the method described in CN101434702A. Specifically, it is composed of a certain proportion of high hydrogen-containing silicone oil (202), octamethylcyclotetrasiloxane (D 4 ) and hexamethyldisiloxane (MM) reaction, adding 5% concentrated sulfuric acid of the total mass of the above materials as a catalyst, reacting at 60-70°C for 3-6 hours, at 120-140°C, 0.1MPa vacuum condition The volatile matter was distilled off to obtain a low hydrogen-containing silicone oil (PHMS) intermediate product. Under nitrogen protection, add catalyst H to α-olefins with a carbon chain length of 12-18 2 PtCl 6 , added dropwise to the above-mentioned low hydrogen-containing silicone oil (PHMS), and reacted at 80°C for 1-4 hours; at 120-140°C, volatile substances were evaporated under 0.01MPa pressure to obtain long-chain alkanes base modified ...

Embodiment 13

[0090] Get 200g NR950 rutile titanium dioxide (purchased from Jinpu Titanium Industry), stir and beat with deionized water to obtain a slurry with a concentration of 240-260g / L, add 0.72g of the silicone oil emulsion prepared in Example 3 of the present invention to it , After stirring for 30min, dry at 110°C for 12h. After grinding, it is pulverized by a jet mill to obtain a titanium dioxide sample.

Embodiment 14

[0092] Use 0.72 g of the silicone oil emulsion prepared in Example 5 of the present invention as a dispersant, and the other steps are the same as in Example 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com