Hydraulic jet energy-saving anti-blocking device

A technology of hydraulic jet and anti-blocking device, which is applied in the direction of cleaning equipment, isolation devices, wellbore/well parts, etc., can solve the problems of ineffectiveness, single viscosity reduction principle, and low efficiency of sonic wax removal technology, so as to increase production , good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

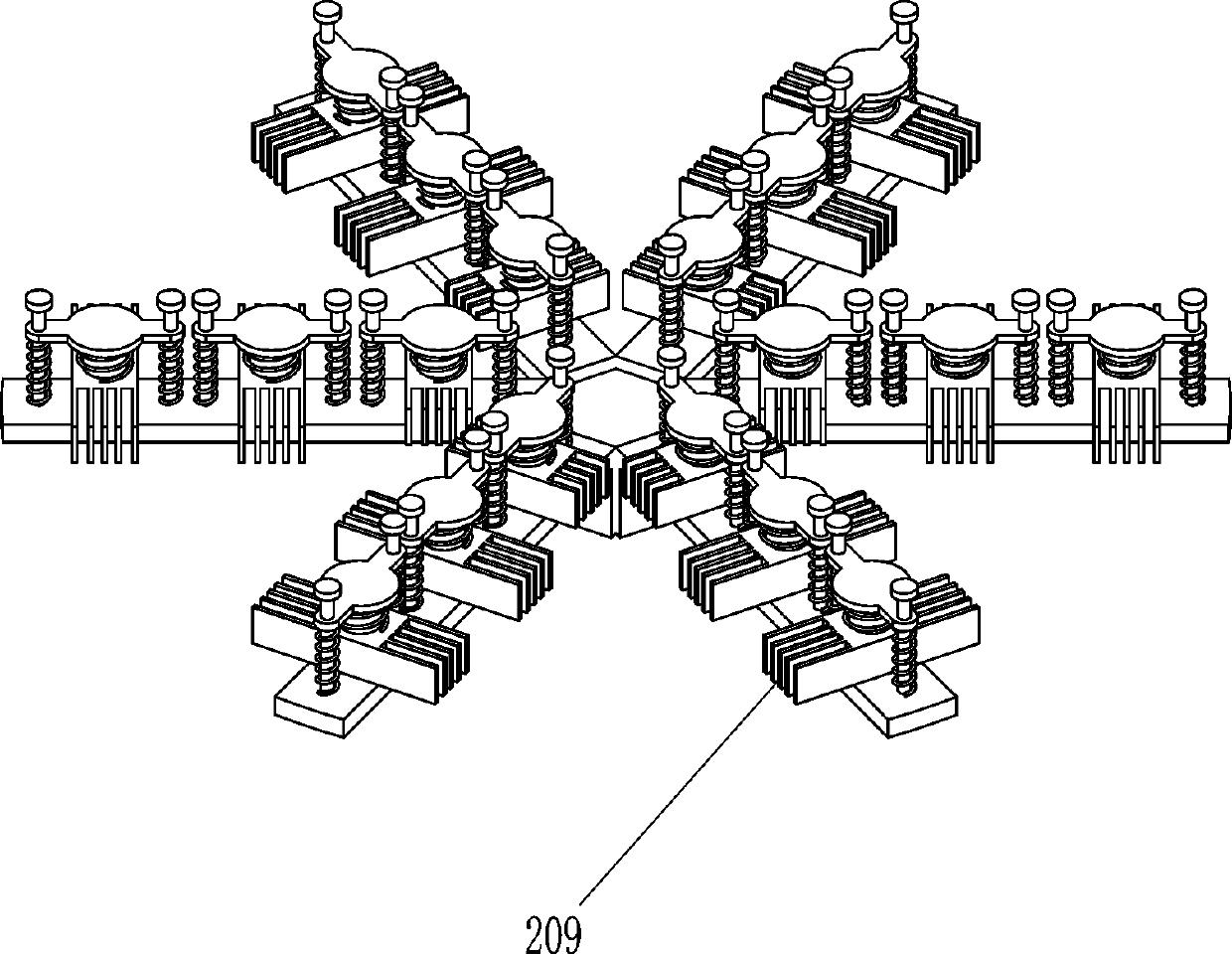

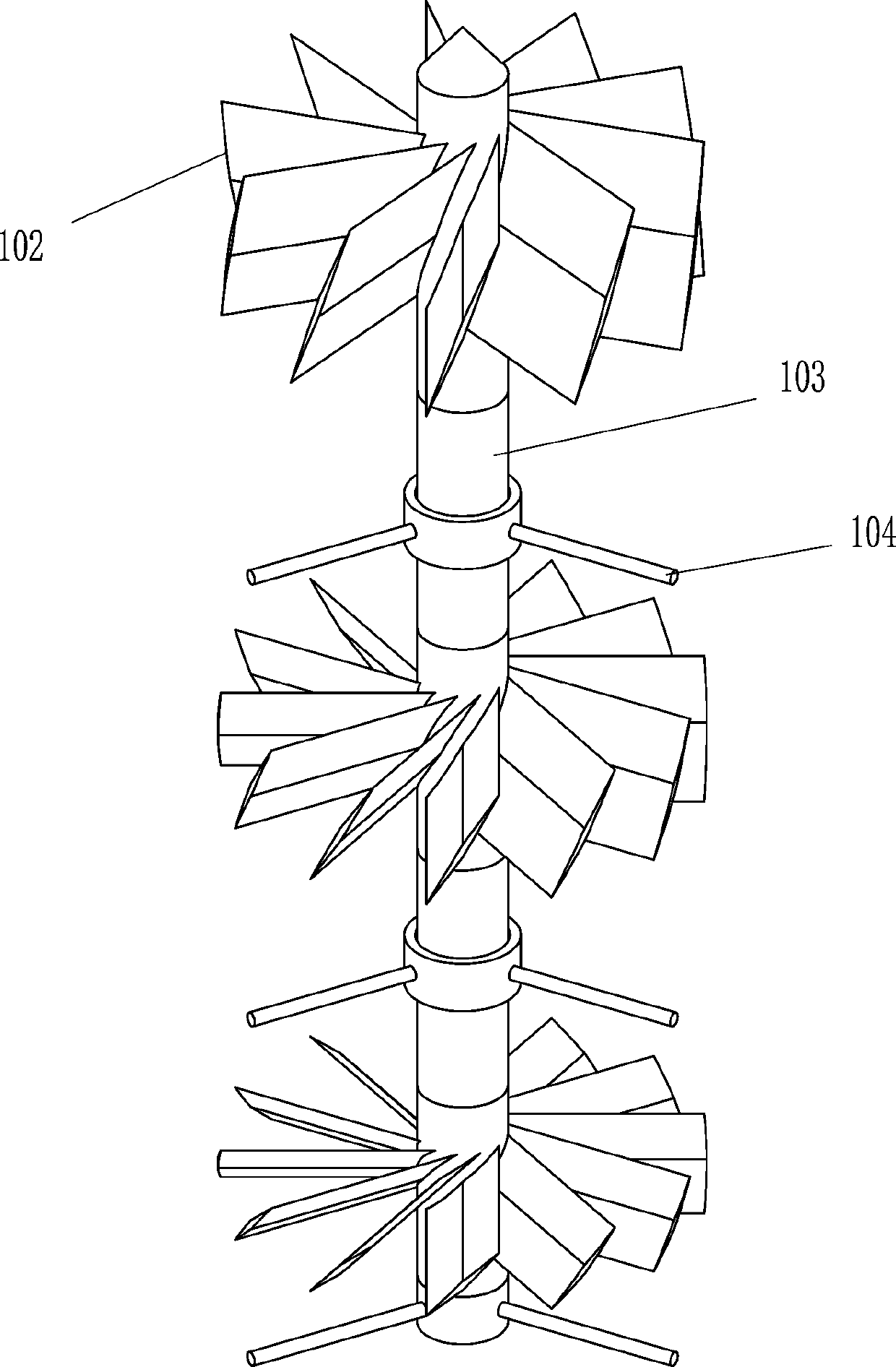

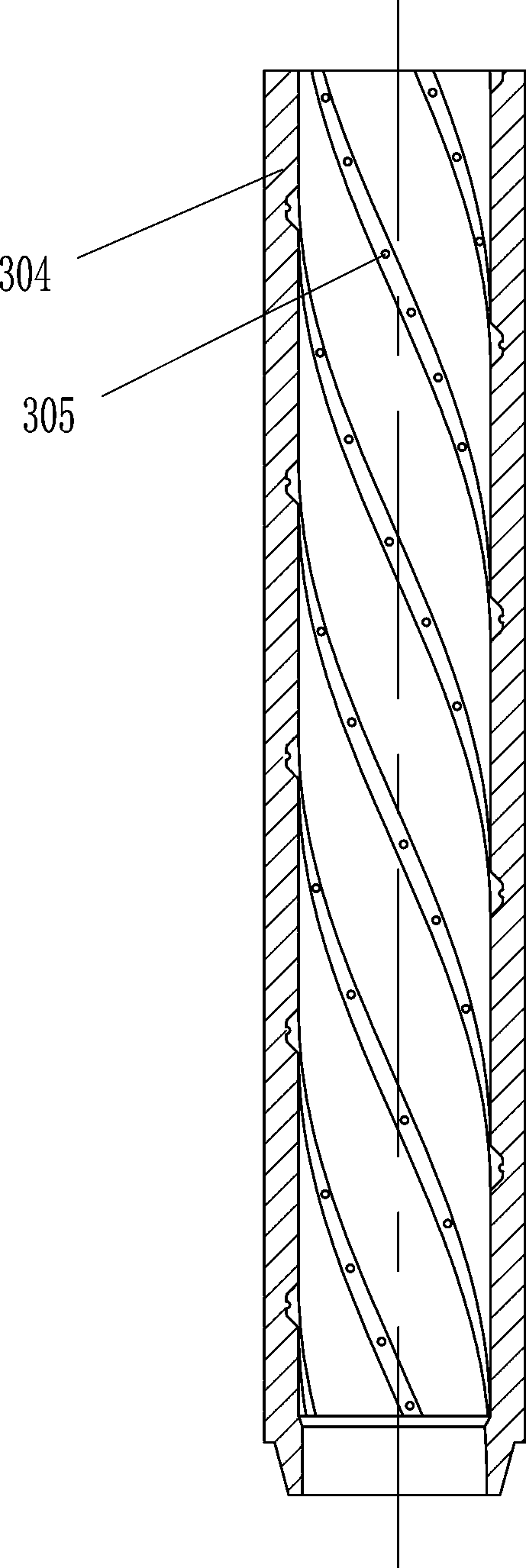

[0029] A hydrojet energy-saving anti-blocking device, such as Figure 1-9As shown, it includes a multi-stage rotary cutting particle refiner 1, a self-heating separator 2, a swirl generator 3 and a multi-stage ultrasonic oscillator 4. The lower side of the multi-stage rotary cutting particle refiner 1 is detachably connected with Self-heating separator 2, the swirl generator 3 is detachably connected to the lower side of the self-heating separator 2, and the swirl generator 3 includes an inner swirl fixed frame 301, a multi-stage inner swirl 302, an arc-shaped inner swirl The flow fixing seat 303, the outer swirl sleeve 304 and the circular convex ball 305, the lower side of the self-heating separator 2 and the upper side of the outer swirl sleeve 304 are detachably connected, and the inner wall of the outer swirl sleeve 304 is processed with an arc Guide groove, the inner wall of the arc-shaped guide groove is discretely distributed with circular convex balls 305, the inner s...

Embodiment 2

[0031] A hydrojet energy-saving anti-blocking device, such as Figure 1-9 As shown, it includes a multi-stage rotary cutting particle refiner 1, a self-heating separator 2, a swirl generator 3 and a multi-stage ultrasonic oscillator 4. The lower side of the multi-stage rotary cutting particle refiner 1 is detachably connected with Self-heating separator 2, the swirl generator 3 is detachably connected to the lower side of the self-heating separator 2, and the swirl generator 3 includes an inner swirl fixed frame 301, a multi-stage inner swirl 302, an arc-shaped inner swirl The flow fixing seat 303, the outer swirl sleeve 304 and the circular convex ball 305, the lower side of the self-heating separator 2 and the upper side of the outer swirl sleeve 304 are detachably connected, and the inner wall of the outer swirl sleeve 304 is processed with an arc Guide groove, the inner wall of the arc-shaped guide groove is discretely distributed with circular convex balls 305, the inner ...

Embodiment 3

[0034] A hydrojet energy-saving anti-blocking device, such as Figure 1-9 As shown, it includes a multi-stage rotary cutting particle refiner 1, a self-heating separator 2, a swirl generator 3 and a multi-stage ultrasonic oscillator 4. The lower side of the multi-stage rotary cutting particle refiner 1 is detachably connected with Self-heating separator 2, the swirl generator 3 is detachably connected to the lower side of the self-heating separator 2, and the swirl generator 3 includes an inner swirl fixed frame 301, a multi-stage inner swirl 302, an arc-shaped inner swirl The flow fixing seat 303, the outer swirl sleeve 304 and the circular convex ball 305, the lower side of the self-heating separator 2 and the upper side of the outer swirl sleeve 304 are detachably connected, and the inner wall of the outer swirl sleeve 304 is processed with an arc Guide groove, the inner wall of the arc-shaped guide groove is discretely distributed with circular convex balls 305, the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com