Existing line tunnel lining structure of railway and construction method thereof

A technology for existing lines and tunnels, which is applied to the lining structure of existing railway line tunnels and its construction, and can solve problems affecting the strength of the existing lining structure, disturbance of the existing lining, and potential safety hazards, so as to reduce potential safety hazards and strengthen construction Convenience and the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

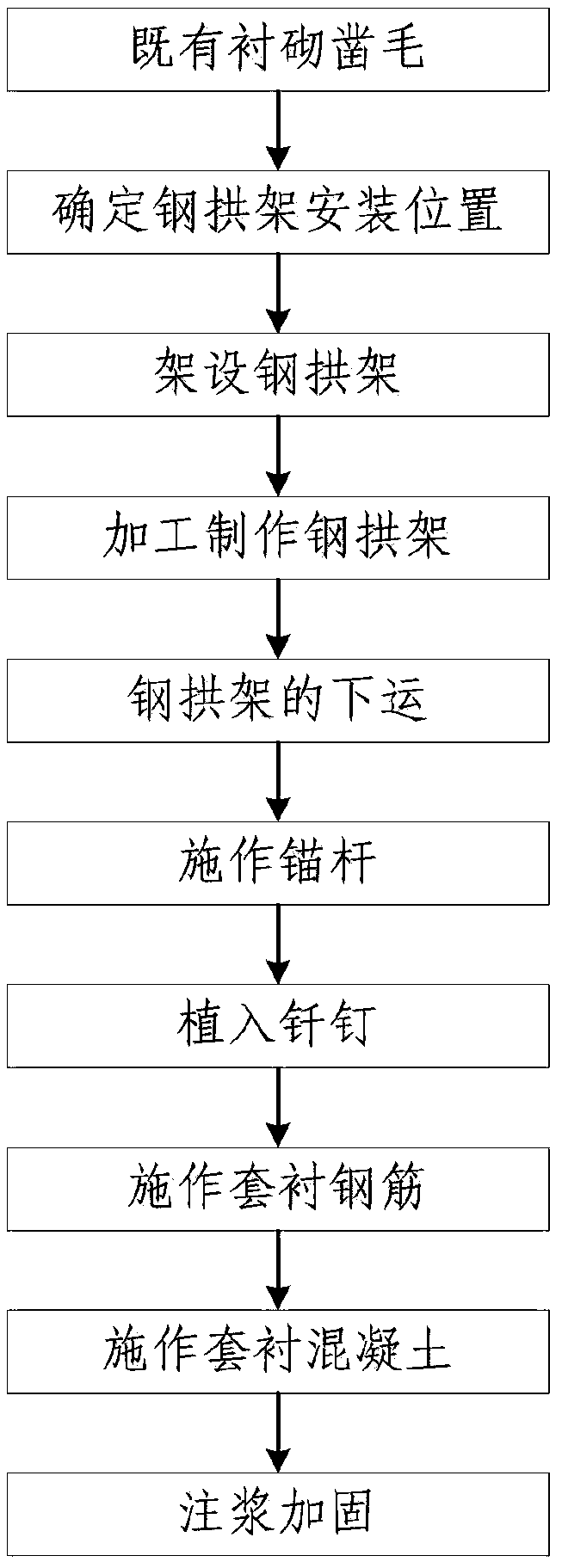

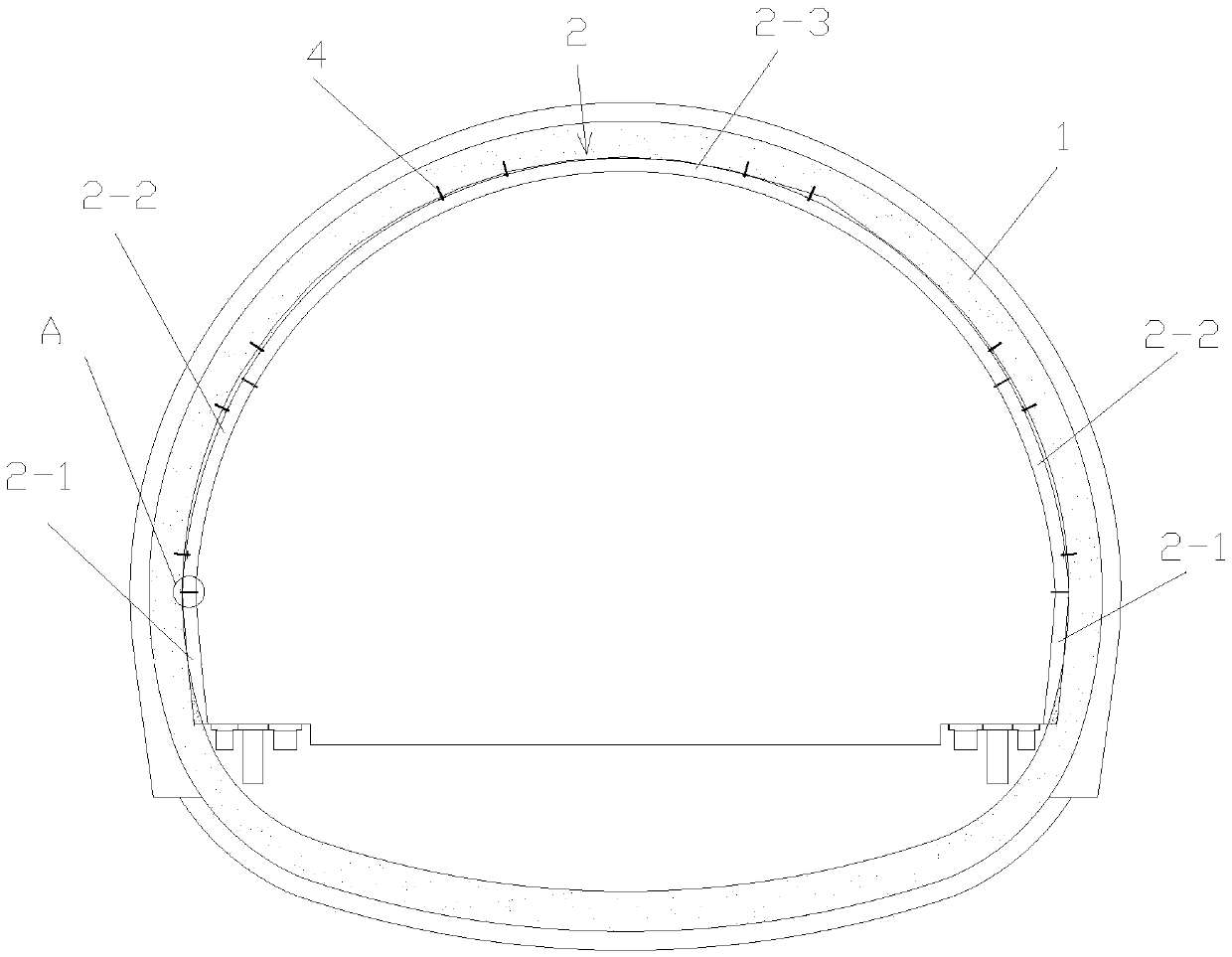

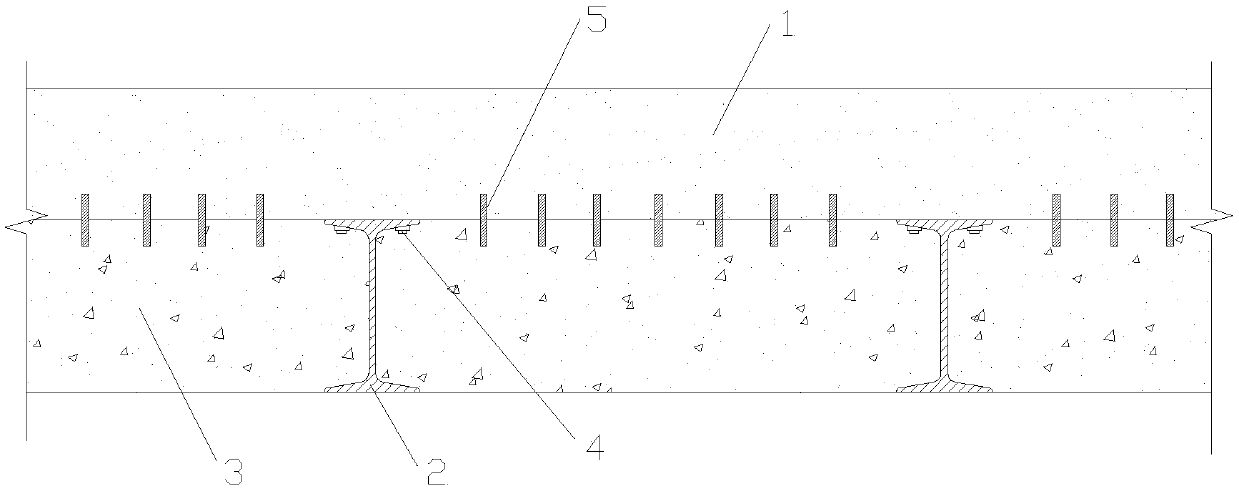

[0047] Such as figure 2 and image 3 The tunnel lining structure of an existing railway line is shown, which includes a multiple steel arch frame 2 arranged on the inner side of the existing lining 1, and a mold for pouring the existing lining 1 and the multiple steel arch frame 2 into one Cast-in-place reinforced concrete lining, the steel arch 2 includes an upper steel arch segment 2-3 and steel arch units symmetrically arranged on both sides of the upper steel arch segment 2-3, the steel arch unit Including the lower steel arch segment 2-1 and the middle steel arch segment 2-2, the lower steel arch segment 2-1, the middle steel arch segment 2-2 and the upper steel arch segment 2 -3 are all fixed on the inner side of the existing lining 1 by expansion bolts 4, and the cast-in-place reinforced concrete lining includes a plurality of linings arranged along the length direction of the existing line tunnel and arranged between two adjacent steel arches 2 A bushing segment 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com